Built-in ltps display panel pixel monitoring system

A technology of display panel and monitoring system, applied in static indicators, instruments, etc., can solve the problems of waste of display screen, incomplete display of information, and inability to determine the specific position or more specific position of dead pixels in the pixel array, etc. achieve direct effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

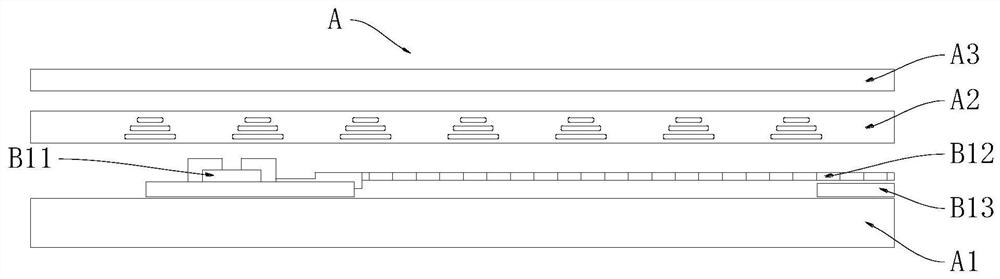

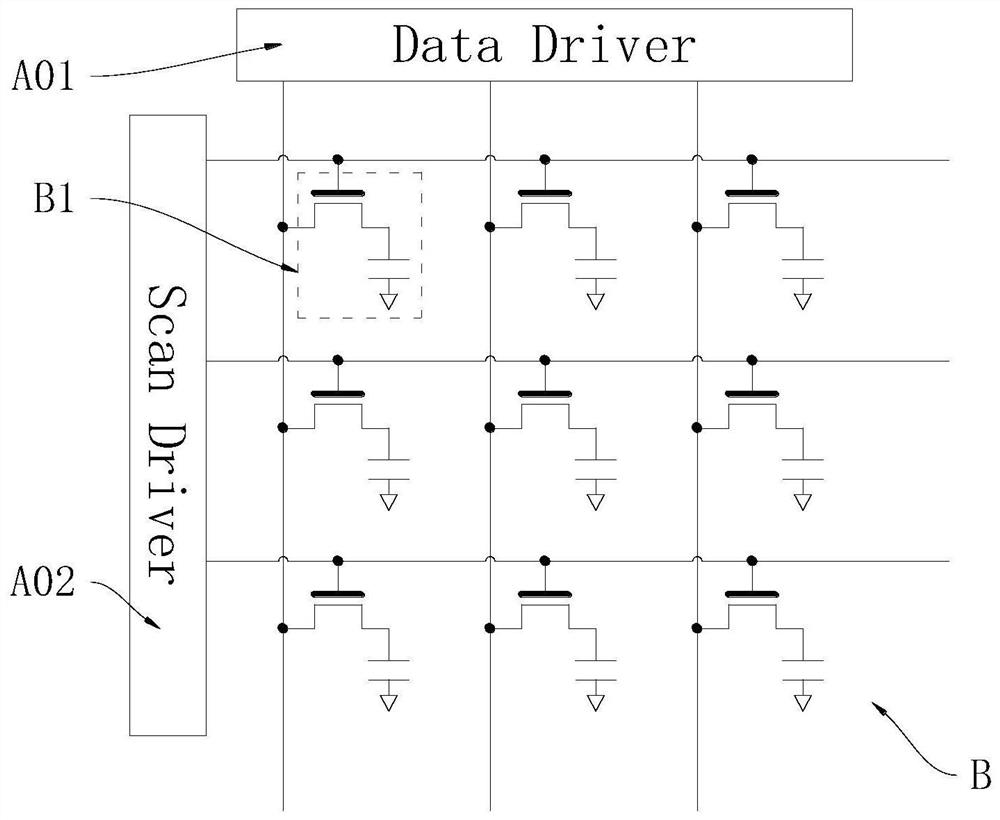

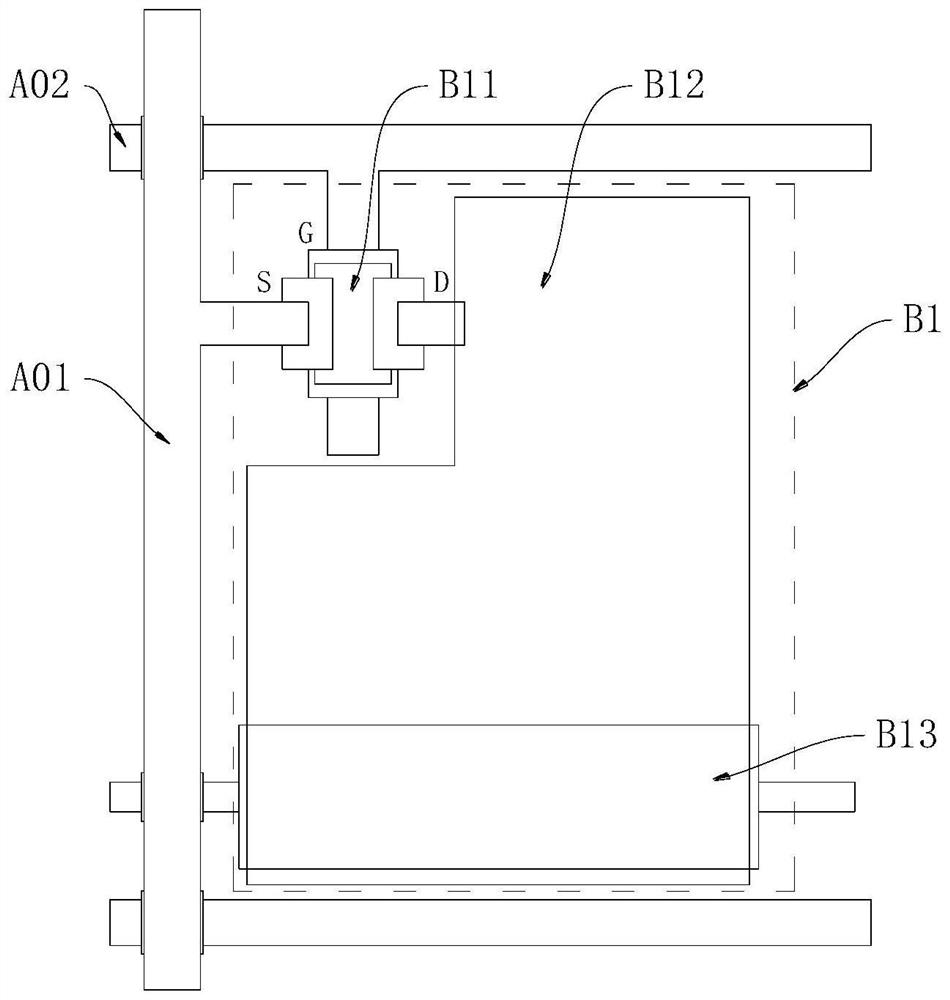

[0040]A built-in LTPS display panel pixel point monitoring system, including a display panel A, the display panel A such asfigure 1 As shown, the panel substrate A1, the liquid crystal layer A2, and the polarizing layer A3 are sequentially included from the inside to the outside. The panel substrate A1 is etched with a pixel point array B of m×n pixels B1, where n is the number of rows, m is the number of columns, such asfigure 2 ,3The pixel point B1 includes a MOSFETB11 and a pixel electrode B12, the source S of the MOSFETB11 is connected to the pixel point data driving line A01, the gate G is connected to the pixel point scanning driving line A02, and the drain D is connected to the pixel electrode B12 , Wherein, a storage capacitor B13 is also provided next to each pixel electrode B12, and its function is similar to that of the pixel electrode B12, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com