Key switch

A switch and button technology, applied in the field of electric switch production, can solve the problem of not being able to completely eliminate the bad state of power-on, and achieve the effect of superior power-on state and full contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

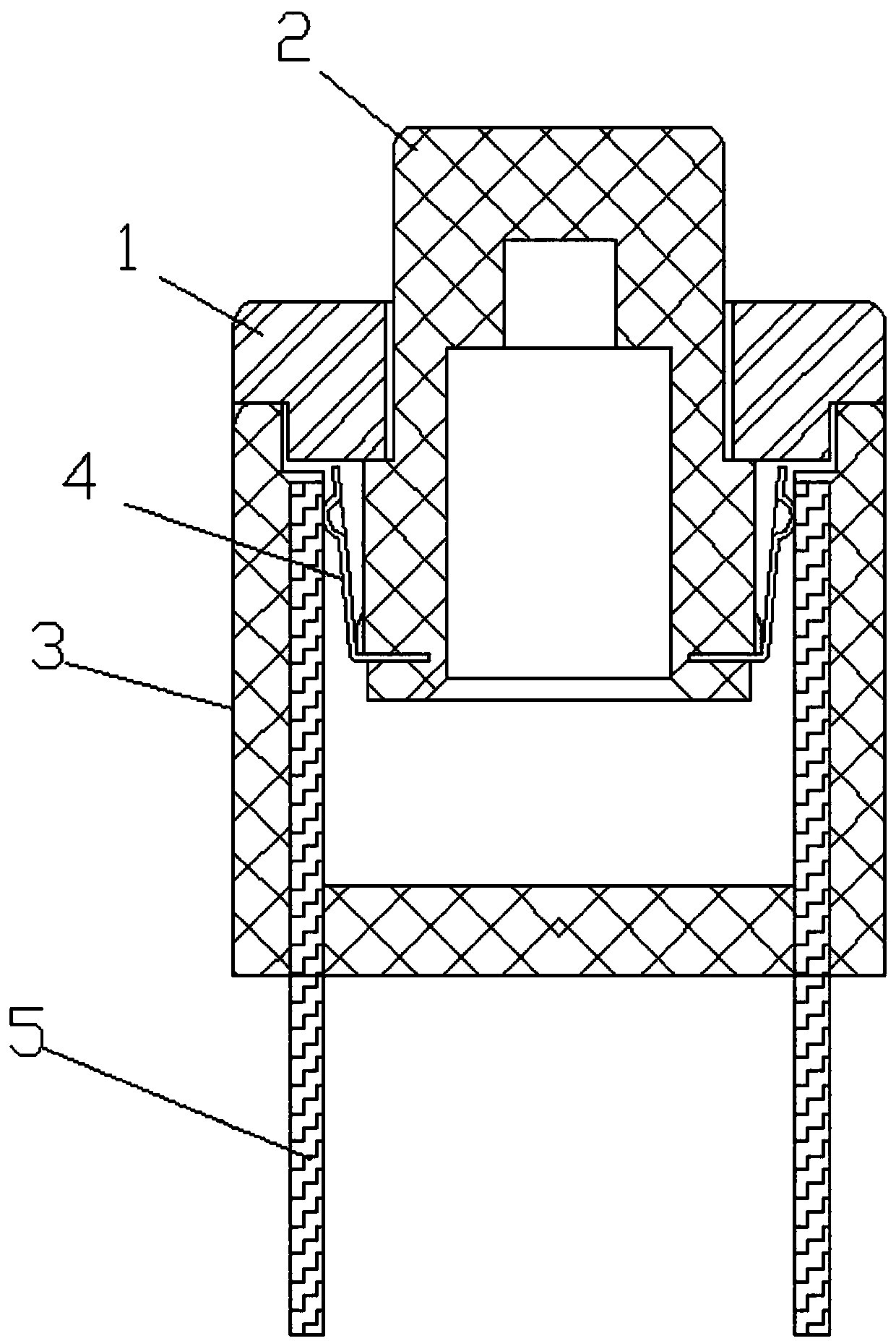

Image

Examples

Embodiment 2

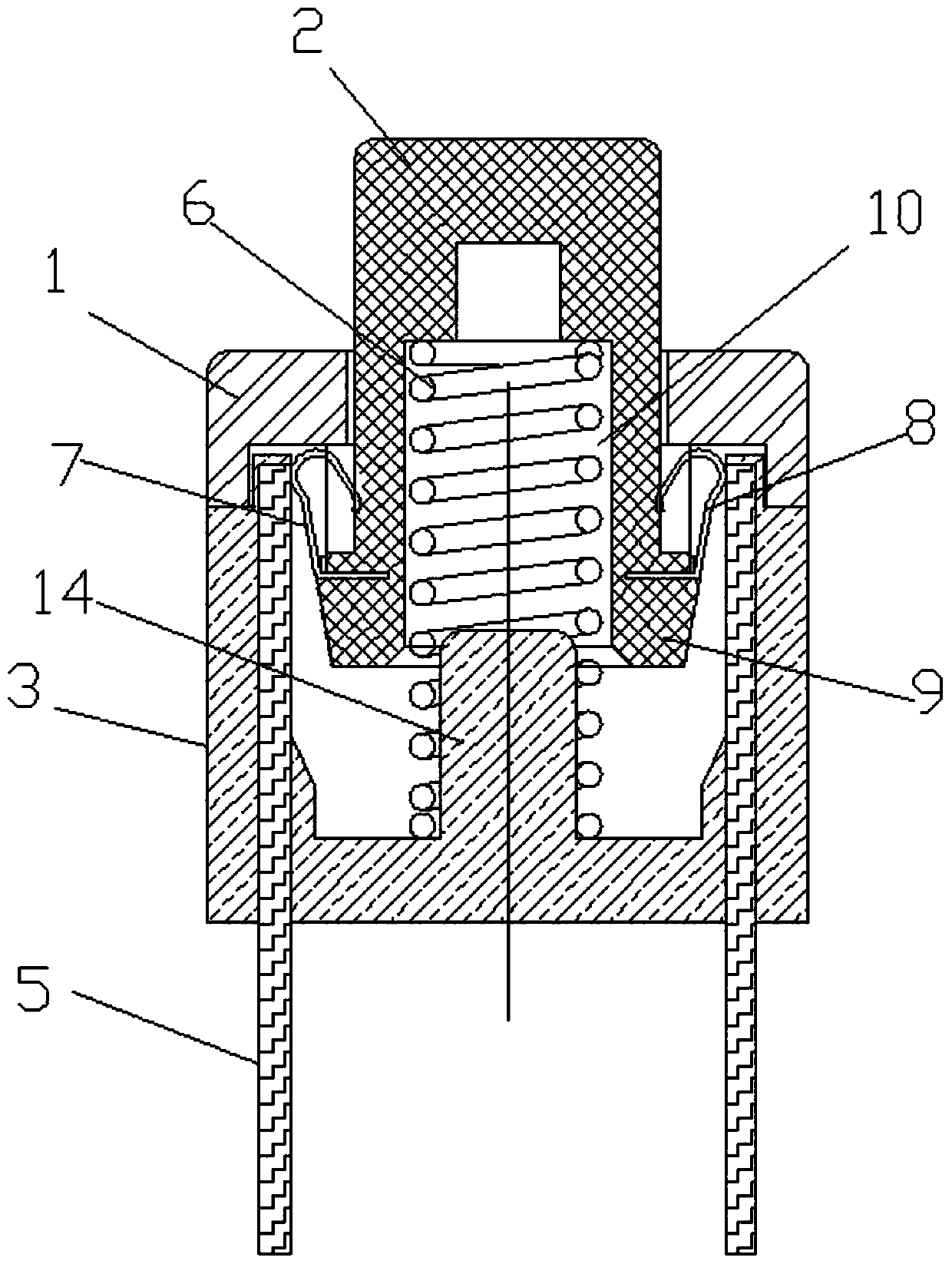

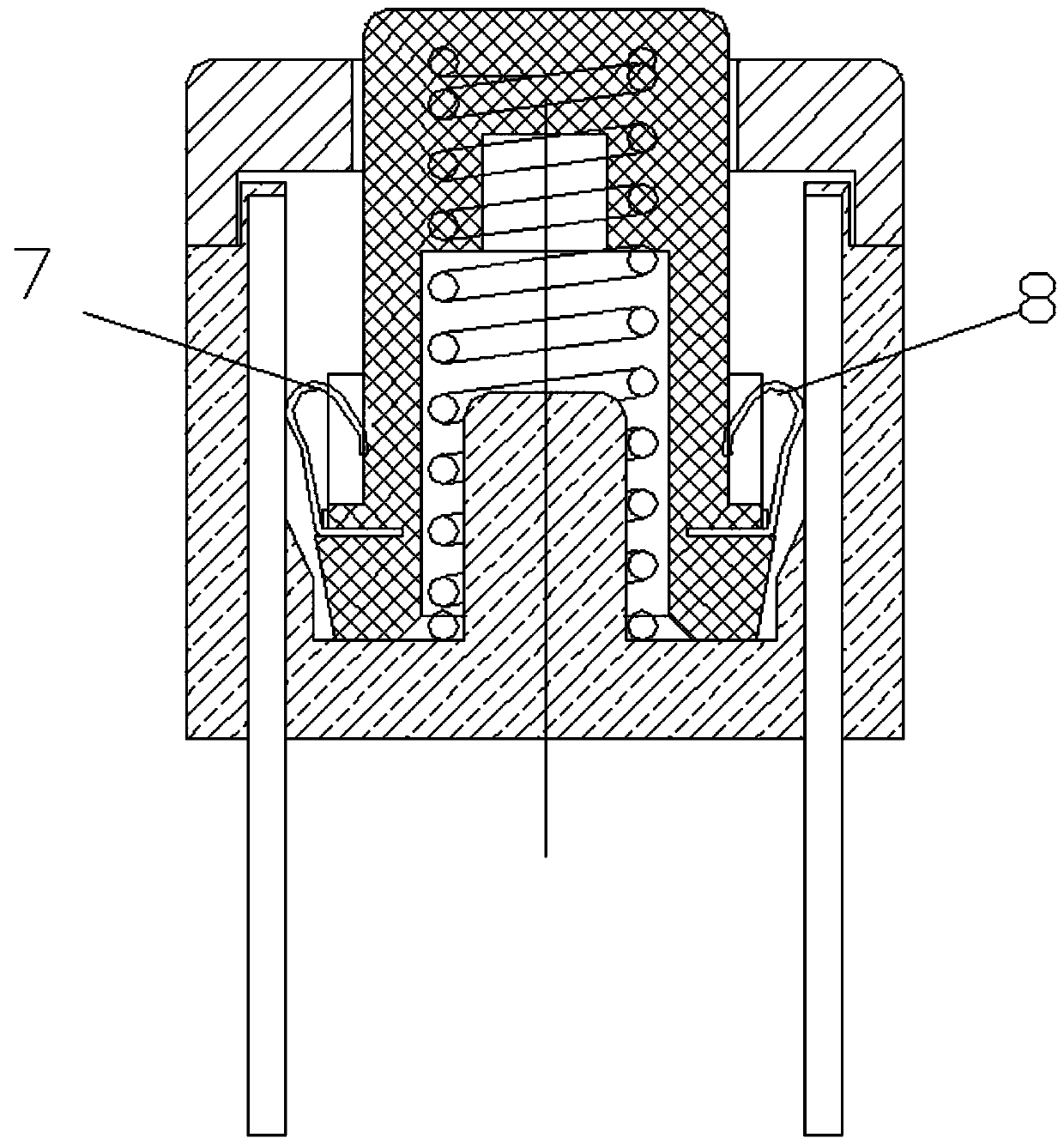

[0032] Figure 5 It is the expression structure of the extended shrapnel of the left shrapnel 7 and the right shrapnel 8, and other structures are not limited thereto.

[0033] The working process of this example: this structure is through the setting of the left elastic piece 7 and the right elastic piece 8, the elastic force of the elastic piece is doubled, so that the contact surface of the elastic piece and the energized foot is completely and fully contacted, so as to achieve a better energized state during the energization process.

[0034] First, through the bending point 15 of the left shrapnel 7 and the right shrapnel 8 (hereinafter, the left shrapnel and the right shrapnel are collectively referred to as shrapnel), the shrapnel is bent to an effective curvature to ensure the shrapnel and the contact point 16 of the energized foot. The contact at this position; at the same time, after assembly, the shrapnel and the plastic contact point 17 of the push shaft are design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com