A polymer pavement brick

A polymer and trail technology, applied in the direction of roads, roads, pavements, etc., can solve the problems of polluting groundwater, occupying land, polluting the environment by harmful gases, etc., and achieves the effect of protection safety, strong pollution resistance, and bright appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

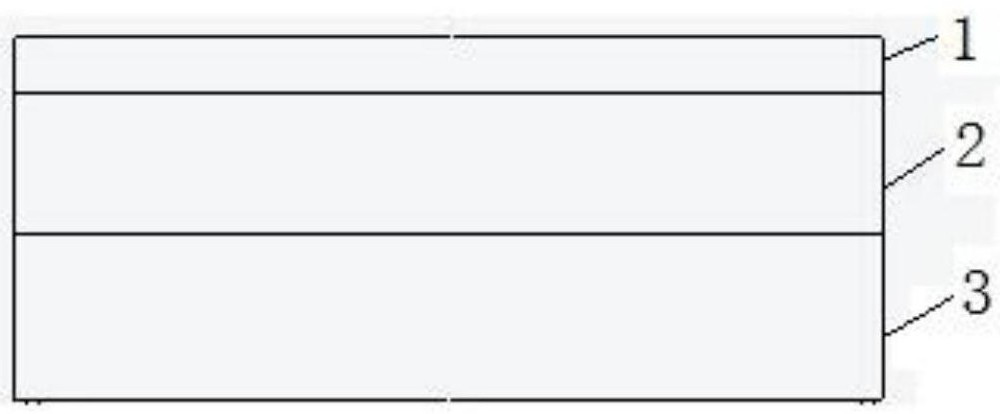

[0011] The main structure of the polymer walkway brick involved in this embodiment includes a surface wear-resistant layer 1, a wear-resistant layer 2 and a reinforcing layer 3; the surface wear-resistant layer 1, the wear-resistant layer 2 and the reinforcing layer 3 are firmly integrated; the surface The wear-resistant layer 1 is composed of 60 parts by weight of benzene unsaturated resin containing accelerator and curing agent, 15 parts of 50-60 mesh glass flakes and 25 parts of 50-100 mesh anti-skid rubber particles. The number of parts consists of 50 parts of benzene unsaturated resin containing accelerator and curing agent, 30 parts of 350-450 mesh glass fiber reinforced plastic particles, 8.3 parts of 300-450 mesh toothpaste grade aluminum hydroxide, 10 parts of 350-400 mesh ceramic beads, 1.5 parts Color paste and 0.2 parts of defoaming agent, reinforcing layer 3 is composed of 20 parts of benzene unsaturated resin containing accelerator and curing agent, 50 parts of po...

Embodiment 2

[0013] The main structure of the polymer walkway brick involved in this embodiment includes a surface wear-resistant layer 1, a wear-resistant layer 2 and a reinforcing layer 3; the surface wear-resistant layer 1, the wear-resistant layer 2 and the reinforcing layer 3 are firmly integrated; the surface The wear-resistant layer 1 is composed of 70 parts by weight of benzene unsaturated resin containing accelerator and curing agent, 15 parts of 50-60 mesh glass flakes and 15 parts of 50-100 mesh anti-skid rubber particles. The number of parts consists of 50 parts of benzene unsaturated resin containing accelerator and curing agent, 30 parts of 350-450 mesh glass fiber reinforced plastic particles, 8.3 parts of 300-450 mesh toothpaste grade aluminum hydroxide, 10 parts of 350-400 mesh ceramic beads, 1.5 parts Color paste and 0.2 parts of defoaming agent, reinforcing layer 3 is composed of 20 parts of benzene unsaturated resin containing accelerator and curing agent, 50 parts of po...

Embodiment 3

[0015] The main structure of the polymer walkway brick involved in this embodiment includes a surface wear-resistant layer 1, a wear-resistant layer 2 and a reinforcing layer 3; the surface wear-resistant layer 1, the wear-resistant layer 2 and the reinforcing layer 3 are firmly integrated; the surface The wear-resistant layer 1 is composed of 60 parts by weight of benzene unsaturated resin containing accelerator and curing agent, 15 parts of 50-60 mesh glass flakes and 25 parts of 50-100 mesh anti-skid rubber particles. The number of parts consists of 45 parts of benzene unsaturated resin containing accelerator and curing agent, 35 parts of 350-450 mesh glass fiber reinforced plastic particles, 8.3 parts of 300-450 mesh toothpaste grade aluminum hydroxide, 10 parts of 350-400 mesh ceramic beads, 1.5 parts The color paste and 0.2 parts of defoamer are composed, and the reinforcing layer 3 is composed of 20 parts by weight of benzene unsaturated resin containing accelerator and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com