High-precision intelligent portable coal-mine gas outburst prediction instrument

A coal mine gas, portable technology, applied in the direction of liquid tightness measurement, instruments, and measuring devices using liquid/vacuum degree, can solve the problems of time parameter gas outburst predictor error, increase measurement failure, cumbersome operation, etc., to achieve Accurate timekeeping, the effect of improving the accuracy of time measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

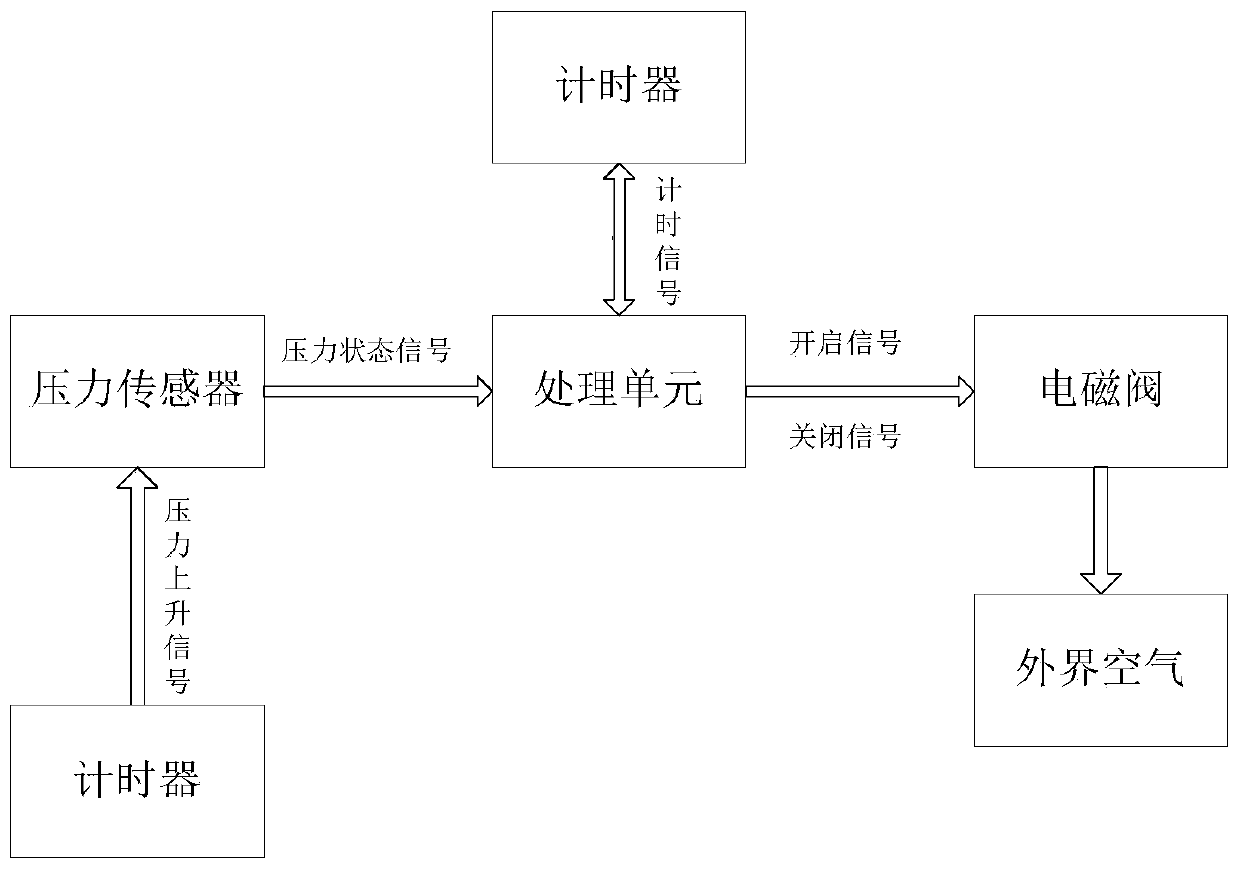

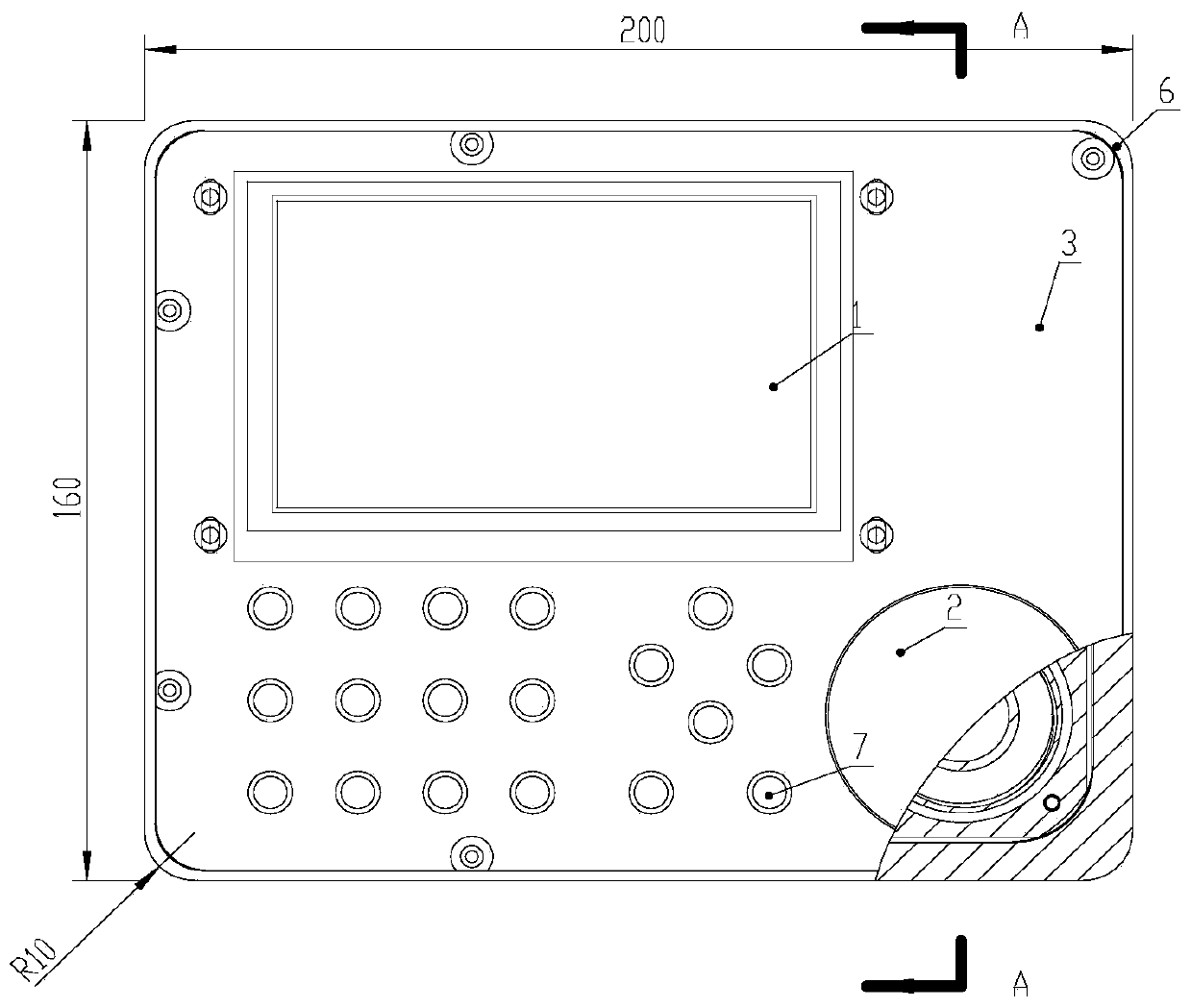

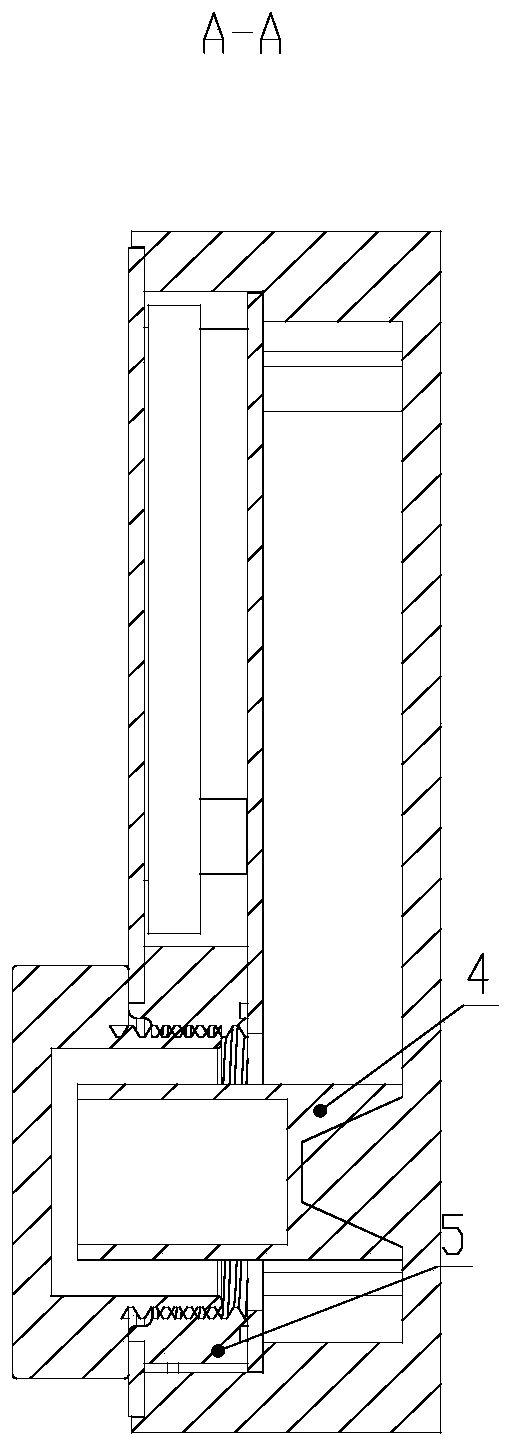

[0036] Such as figure 1 As shown, a high-precision intelligent portable coal mine gas outburst predictor includes a gas chamber 13 with a first straight hole 10, and also includes: a pressure sensor 9 that sends a pressure state signal after obtaining a pressure rise signal, and receives the pressure state signal. The processing unit 7 that sends the opening signal and the timing signal, the solenoid valve that opens the first straight hole 10 after obtaining the opening signal, the timer that obtains the timing signal and sends the timing completion signal after the timing is completed, and the control that sends the closing after the timing signal is obtained The signal processing unit 7 closes the solenoid valve of the first straight hole 10 after obtaining the closing signal; the first straight hole 10 is provided with a pressure sensor 9 .

[0037] In the prior art, the air in the air chamber is compressed during the tightening process of the air chamber cover 2. At this ...

Embodiment 2

[0039] Such as figure 1 As shown, this embodiment provides a gas outburst prediction method on the basis of Embodiment 1. When the hole is turned, it is a trigger signal. After the timer receives the trigger signal, it records this moment and then records this moment T1. After the sample is tightened, a pressure rise signal is generated, and the pressure sensor 9 obtains the pressure rise signal and sends it to the processing unit 7. After receiving the pressure rise signal, the processing unit 7 sends an opening signal to the solenoid valve and simultaneously sends a timing signal to the timer. The timer Start timing after receiving the timing, the timing time is X, and after the timing is completed, the first timing completion signal is fed back to the processing unit 7, and after the processing unit 7 receives the first timing completion signal, it sends a closing signal to the solenoid valve and records This moment is T2, the solenoid valve closes the first straight hole 1...

Embodiment 3

[0044] Such as figure 1 As shown, the present embodiment is improved on the basis of embodiment 2;

[0045] After the solenoid valve closes the first straight hole 10, the timing signal is sent to the processing unit 7 again, and the processing unit 7 sends the timing signal to the timer after obtaining it. The timer starts counting after receiving the timing, and the timing time is the preset time Y , and after the timing is completed, the second timing completion signal is fed back to the processing unit 7. After the processing unit 7 receives the second timing completion signal, it sends an opening signal to the solenoid valve and records this moment as T3, and the solenoid valve opens for the first time. For the straight hole 10, the processing unit 7 obtains the second time period as T3-T2. The time period T3-T2 plays a key role in subsequent accurate measurement

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com