A fully automatic shoe washing machine

A shoe washing machine, fully automatic technology, applied in the direction of cleaning boots and shoes, household cleaning devices, household appliances, etc., can solve the problems of wasting water resources, shoes are easy to get dirty, easy to wet, etc., and achieve the effect of easy access to shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

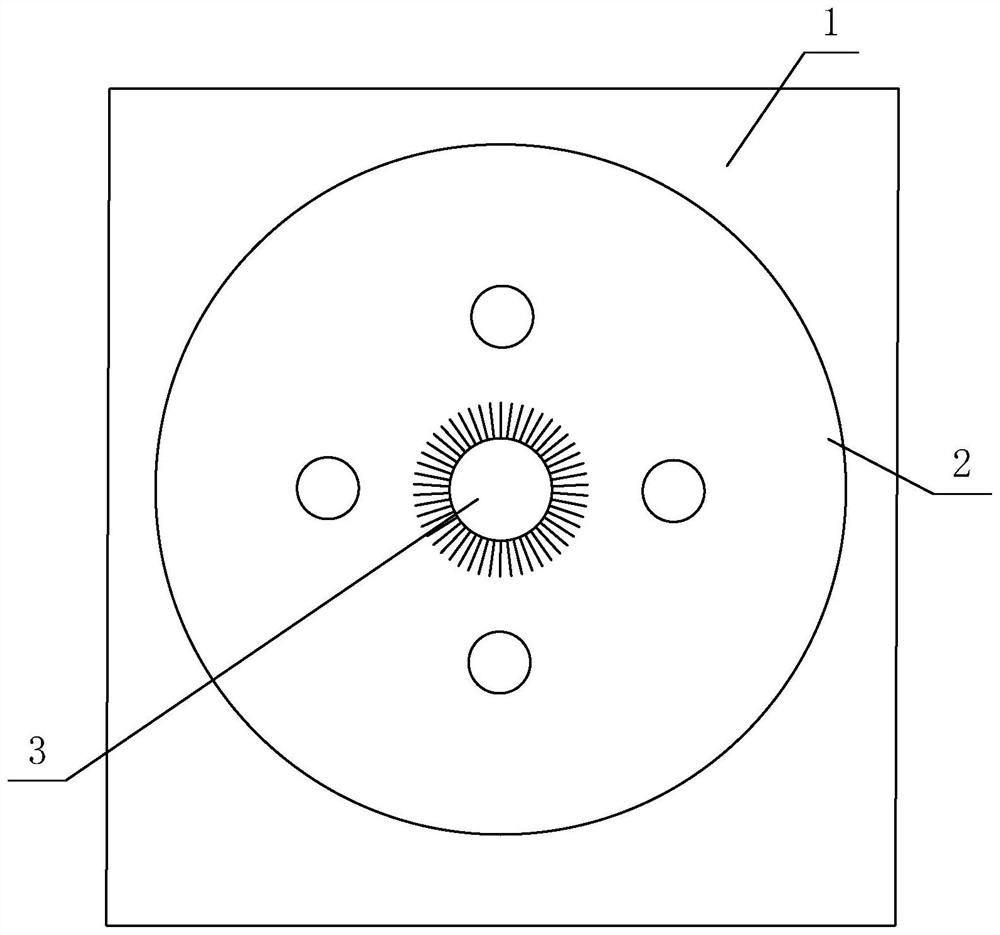

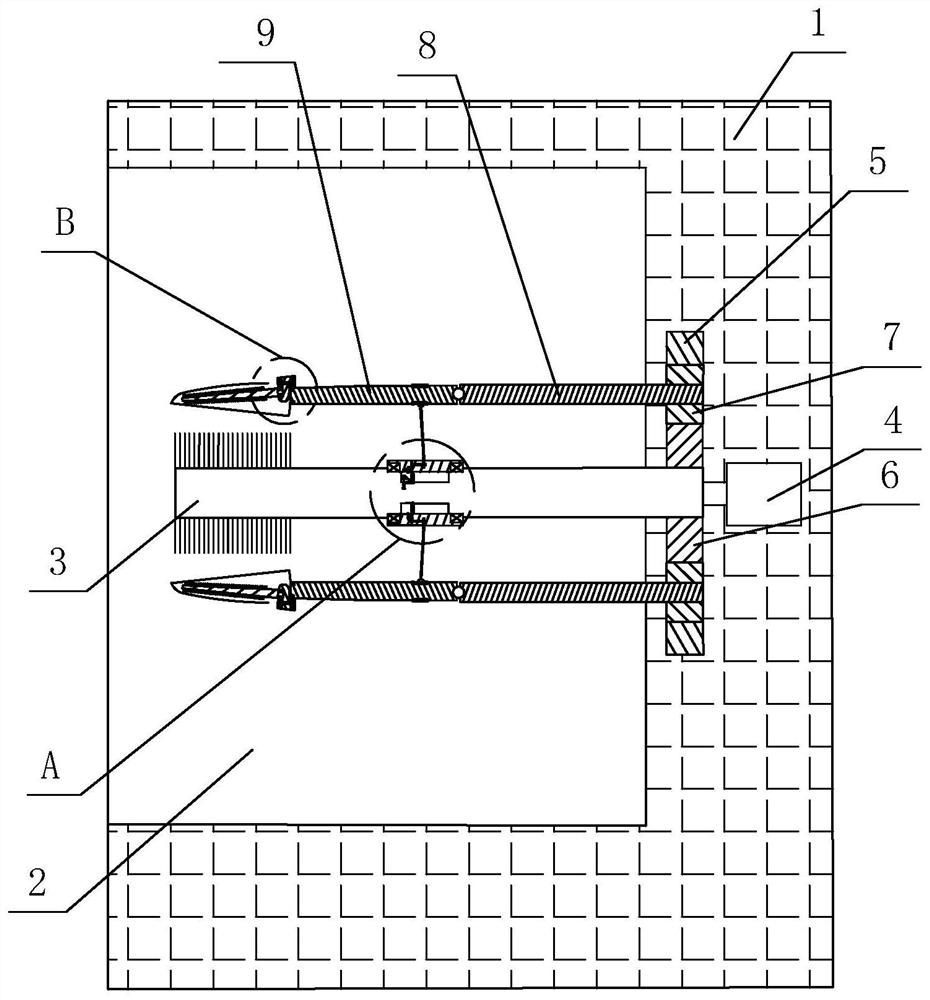

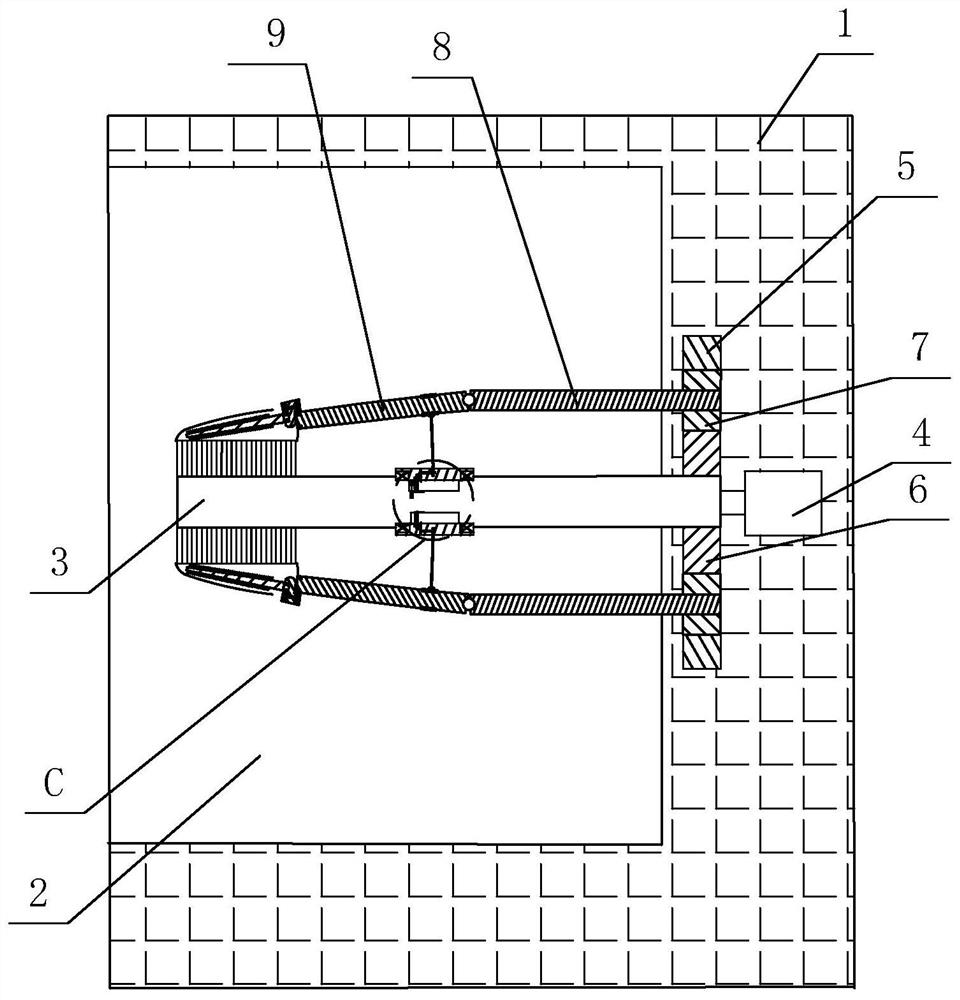

[0019] Such as Figure 1 to Figure 7 As shown, a fully automatic shoe washing machine includes a body 1, a motor 4 and a washing bucket 2 disposed in the body 1, the opening of the washing bucket 2 is hinged with a sealed door, and the upper and lower ends of the body 1 are respectively provided with water injection pipes and The water outlet, the water injection pipe, and the water outlet are all connected to the washing bucket 2. The planetary gear structure located on the right side of the washing bucket 2 is arranged in the body 1. The planetary gear structure includes a planetary frame 5 and a main shaft gear 6 located in the middle of the planetary frame 5. There are several inner ring gears 7 engaged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com