Device integrating rearview mirror adjusting switch and rearview mirror reversing and downward-turning main machine

A technology for adjusting switches and rear-view mirrors, applied in the field of auto parts, can solve the problems of complex wiring harness in the car, time-consuming and laborious, unfavorable parts replacement or maintenance, etc., to avoid reversing accidents, improve safety, and facilitate the effect of modification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

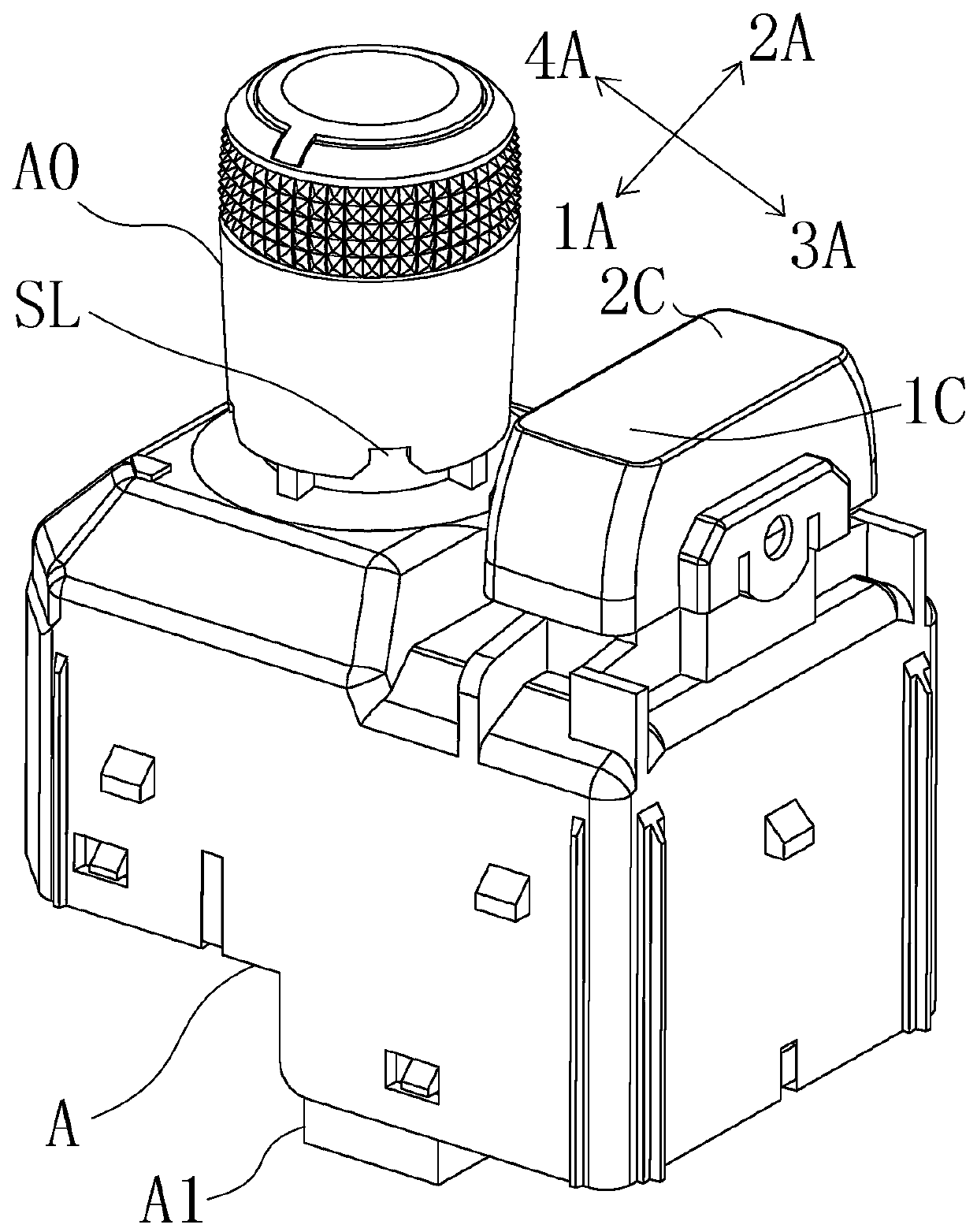

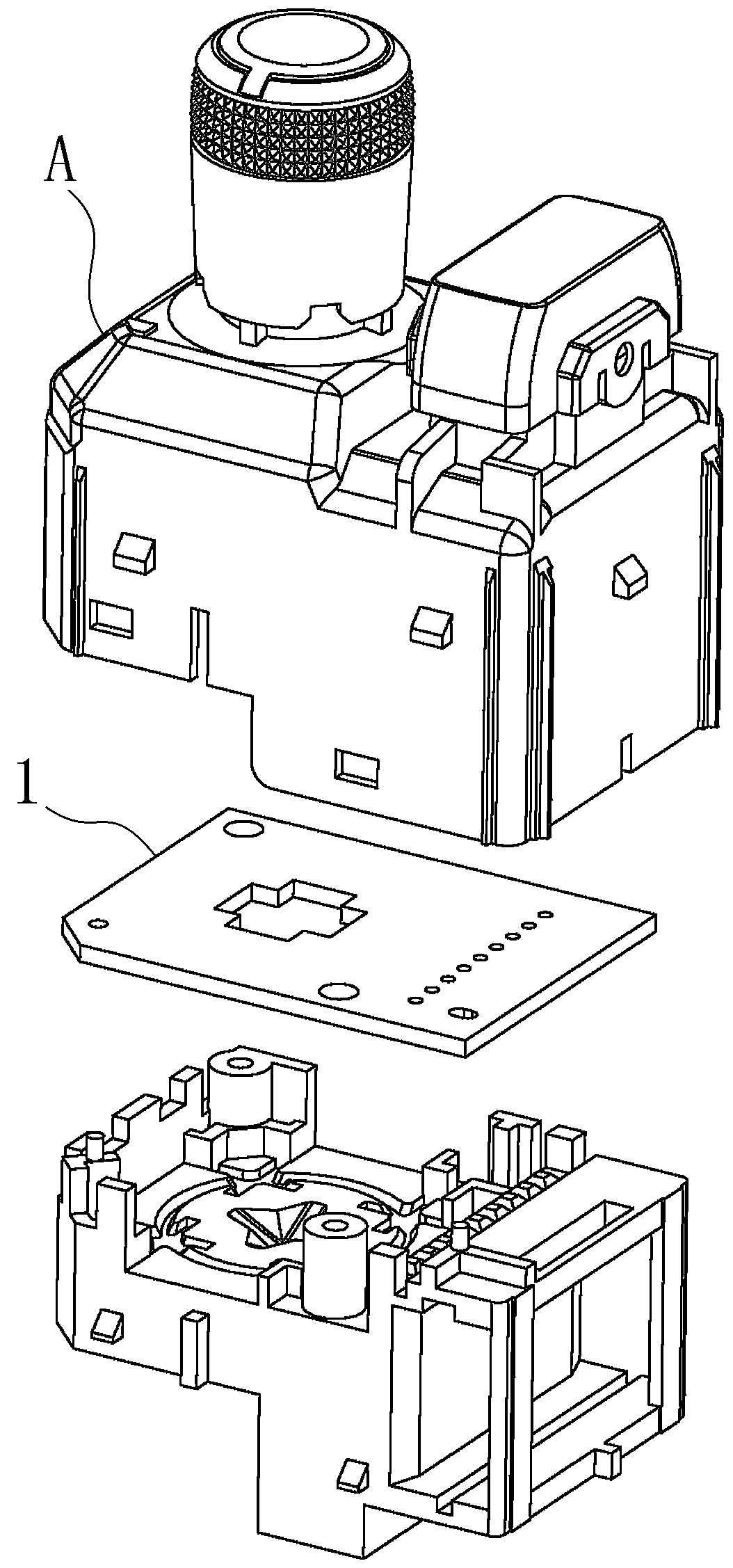

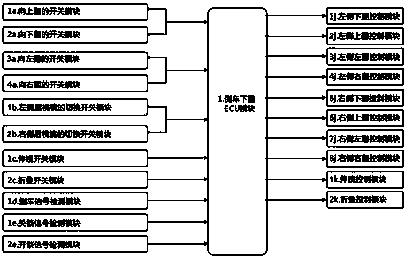

[0029] Such as figure 1 , 2 , the rearview mirror is reversed and turned down. The shell of the host A is equipped with a rotary rocker switch A0. The rearview mirror adjustment switch is the rocker direction gear switch of the rotary rocker switch A0. Rotary range switch for lever switch A0.

Embodiment 2

[0031] Such as Figure 10 As shown, the flip-up switch 1A, the flip-down switch 2A, the flip-to-left switch 3A and the flip-to-right switch 4A on the housing of the host A when the rearview mirror reverses and flips down are closely arranged in the shape of a "field". The selection switch SL is provided beside the flip-up switch 1A, the flip-down switch 2A, the flip-left switch 3A, and the flip-right switch 4A.

Embodiment 3

[0033] Such as Figure 11As shown, the housing of the rearview mirror reversing and downturning host A is provided with a rotary rocker switch A0, and the rearview mirror adjustment switch is the rocker direction gear switch of the rotary rocker switch A0. The difference from Embodiment 1 is that The rearview mirror adjustment switch SL, the mirror extension switch 1C and the folding switch 2C are integrated in the rotary position switch of the rotary rocker switch A0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com