Integrated electromagnetic head structure

A technology of solenoid head and armature push rod, which is applied in the direction of valve details, engine components, valve operation/release devices, etc., can solve the problems of complex structure, many parts and high cost of solenoid valves, reduce assembly requirements and reduce production costs , the effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

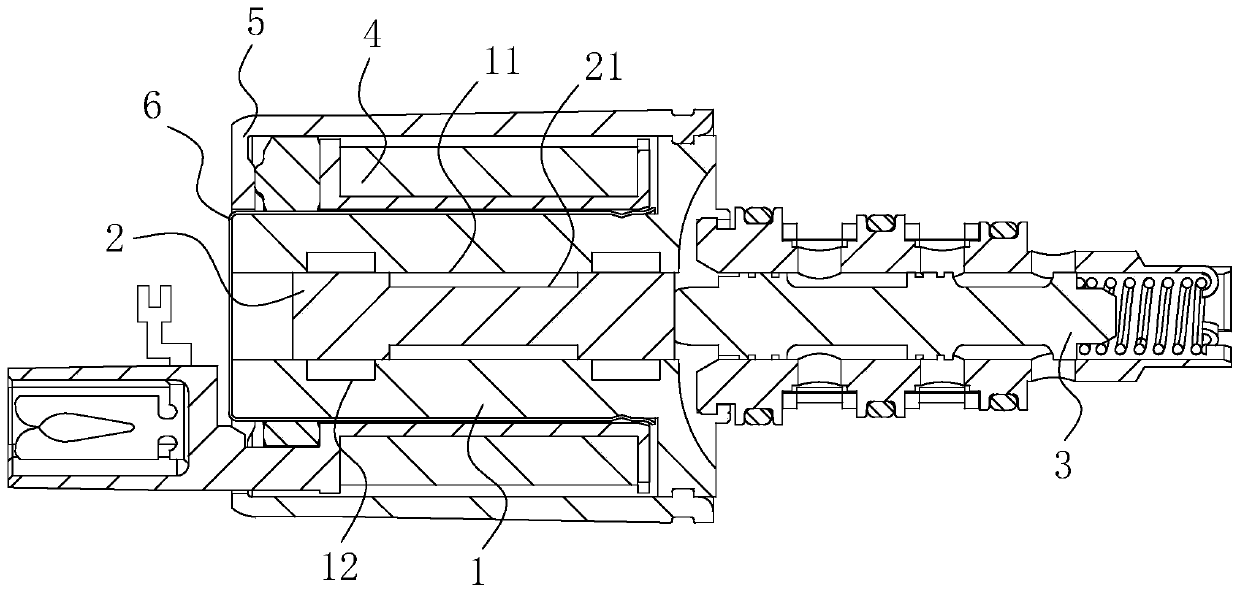

[0019] An integrated magnetic head structure, refer to figure 1 , which includes a housing 5, the housing 5 is provided with an iron stopper 1, the middle of the iron stopper 1 is provided with a slide hole 11, and the slide hole 11 is provided with an armature push rod 2; in this embodiment, the iron stopper 1 is T-shaped as a whole, It can also be in the shape of a straight cylinder; the iron stopper 1 is covered with an end cover 6, so that one end of the sliding hole 11 can be closed; a coil 4 is arranged between the shell 5 and the iron stopper 1, and the coil 4 generates electromagnetic force after being energized to control The armature push rod 2 moves, and after the armature push rod 2 moves, the valve core 3 in the electromagnetic valve is pushed to move, so as to realize the function of the electromagnetic valve.

[0020] A stepped ring groove 21 is provided in the middle of the side wall of the armature push rod 2, so that the armature push rod 2 is in the shape of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com