Multi-milling cutter processing device of multi-groove carving drilling rod

A technology of processing equipment and milling cutters, which is applied in the direction of metal processing equipment, milling machine equipment, milling machine equipment details, etc., can solve problems such as weak slag discharge ability, drill sticking, drilling blockage, etc., achieve consistent speed and depth, and improve production efficiency , to ensure the effect of quality and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

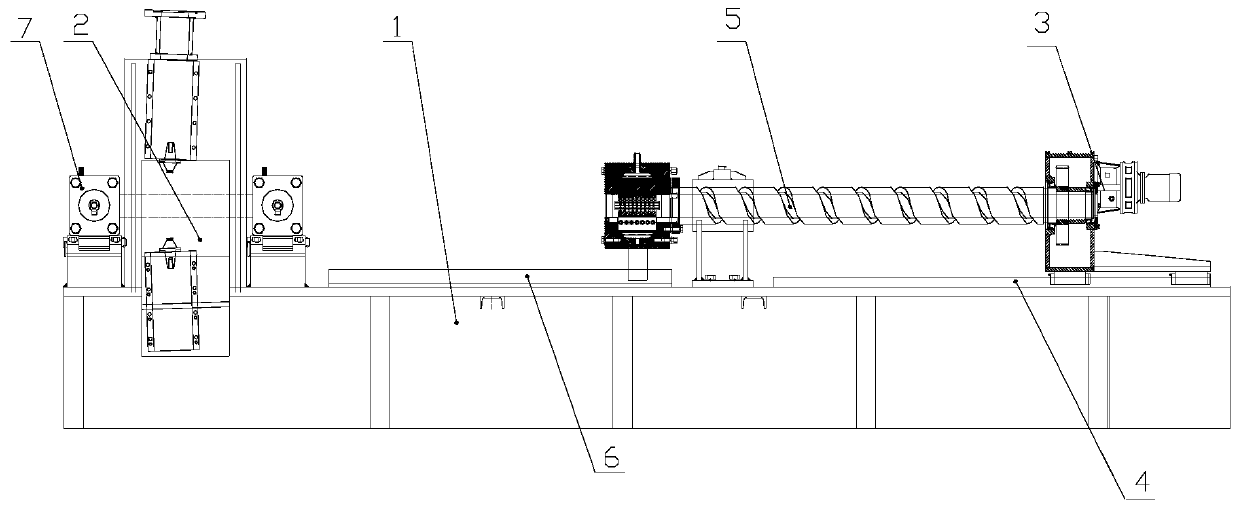

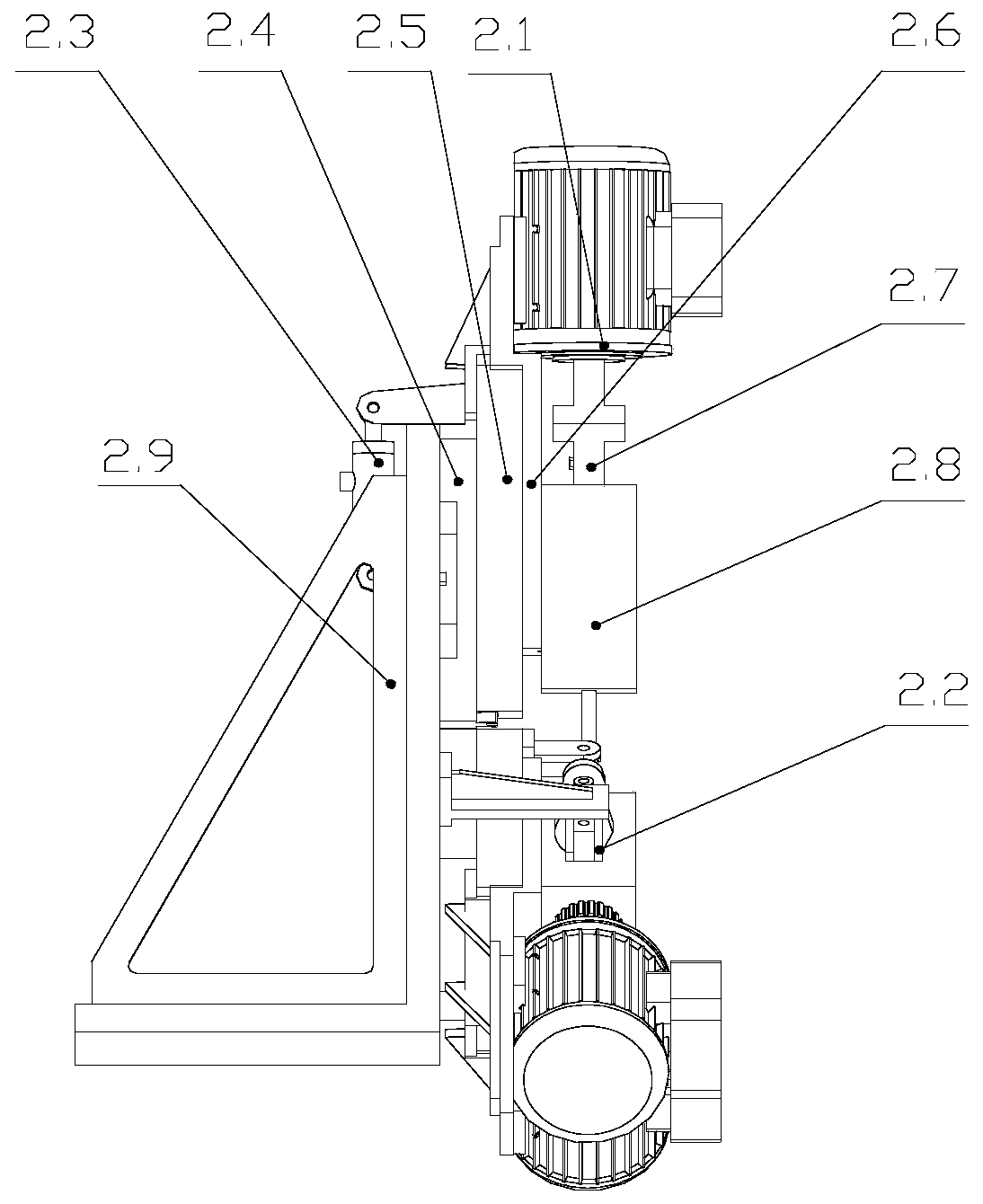

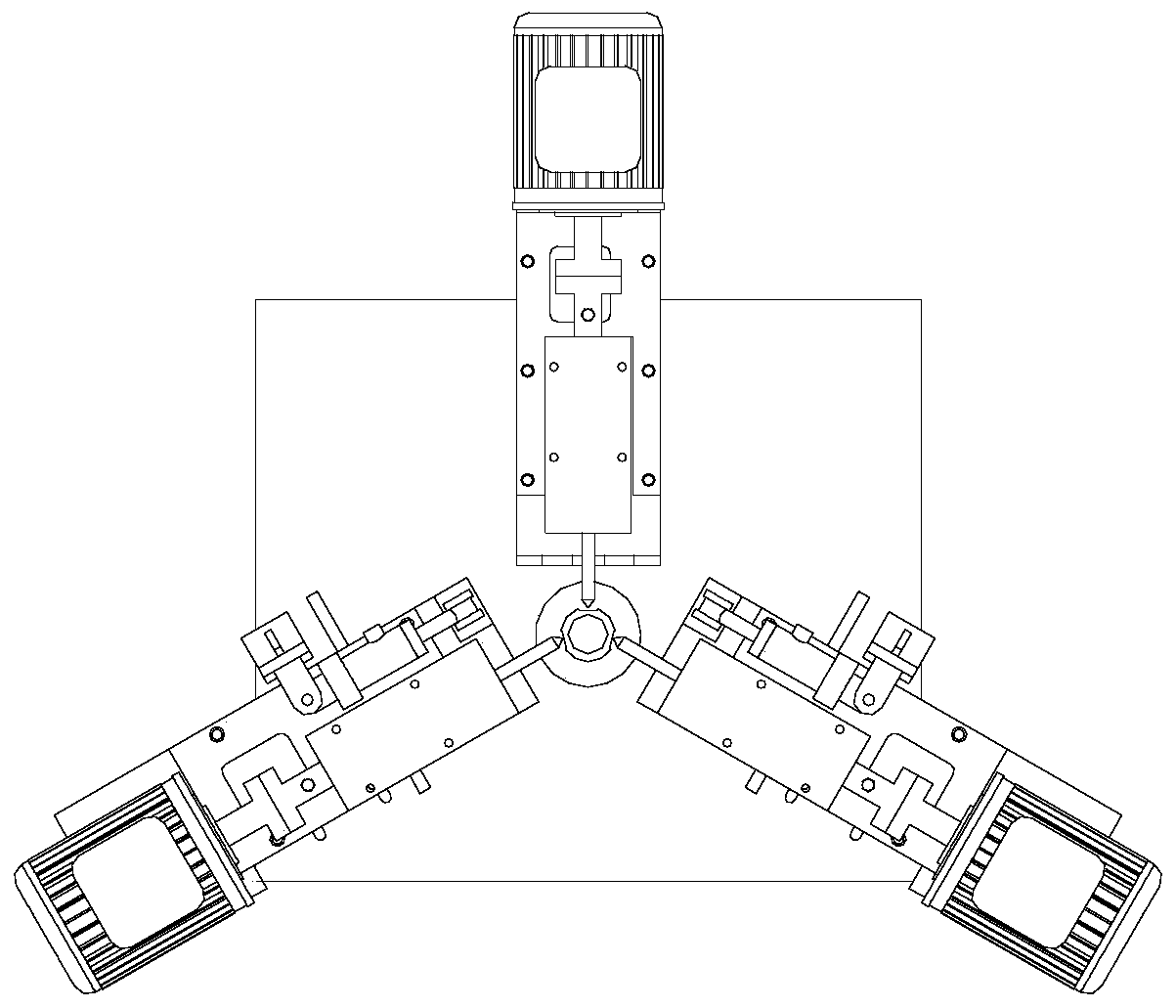

[0029] Such as figure 1 As shown, a multi-milling cutter processing equipment for a multi-grooved drill rod in this embodiment includes a frame 1 placed on the ground and a milling mechanism 2, and the milling mechanism 2 is installed on the discharge port of the frame 1. At the inlet position of the frame 1, a drive mechanism 3 is installed on the side of the feed port of the frame 1, and the drive mechanism 3 cooperates with the frame 1 through the first linear guide rail 4, so that the drive mechanism 3 can be processed along the drill pipe of the frame 1 Direction movement, a screw guide assembly 5 is installed at the output end of the drive mechanism 3, and the screw guide assembly 5 is slidingly connected with the frame 1 through the second linear guide rail 6, and the screw guide assembly 5 connects the feed port side The drill rod is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com