Cup printing machine equipment

A cup printing machine and cup printing technology, applied in the field of cup printing machine equipment, can solve the problems of difficulty in processing different types of cups, inconvenient maintenance, poor stability, etc., and achieve the effects of reducing procurement costs, easy maintenance, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

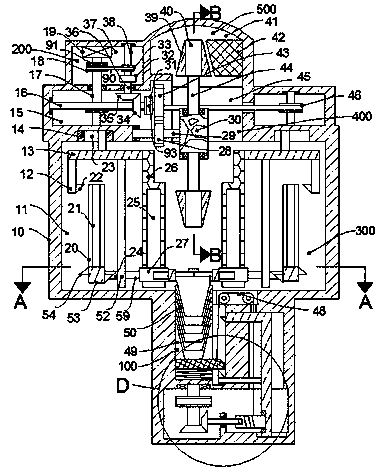

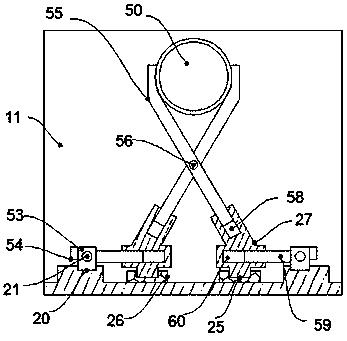

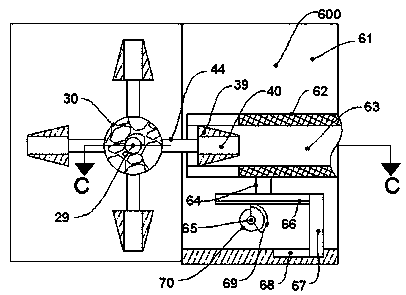

[0019] Such as Figure 1-5 As shown, a kind of cup printing machine equipment of the device of the present invention includes a cup printing box 10 and a cup putting chamber 49 arranged in the cup printing box 10, and a cup feeding device 100 is arranged in the cup putting chamber 49, so that A cup 50 is placed in the cup delivery device 100, a clamping chamber 11 is provided in the printed cup box 10, a clamping device 300 is provided in the clamping chamber 11, and a clamping device 300 is provided with a Moving threaded block 53, described printing cup box 10 is provided with transposition cavity 45, and described transposition cavity 45 is provided with transposition device 400, and described transposition device 400 is provided with described cup 50 to match The cup sleeve 39, the transposition device 400 is provided with an adsorption device 40 for sucking the cup 50, the printing cup box 10 is provided with a printing chamber 41, and the printing chamber 41 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com