Self-positioning tilting-pad bearing structure of marine movable nuclear power turbine

A mobile, steam turbine technology, applied to sliding contact bearings, rotating bearings, bearings, etc., can solve problems such as bearing misalignment, bearing bush wear, etc., and achieve the effect of improving safety, reliability and maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

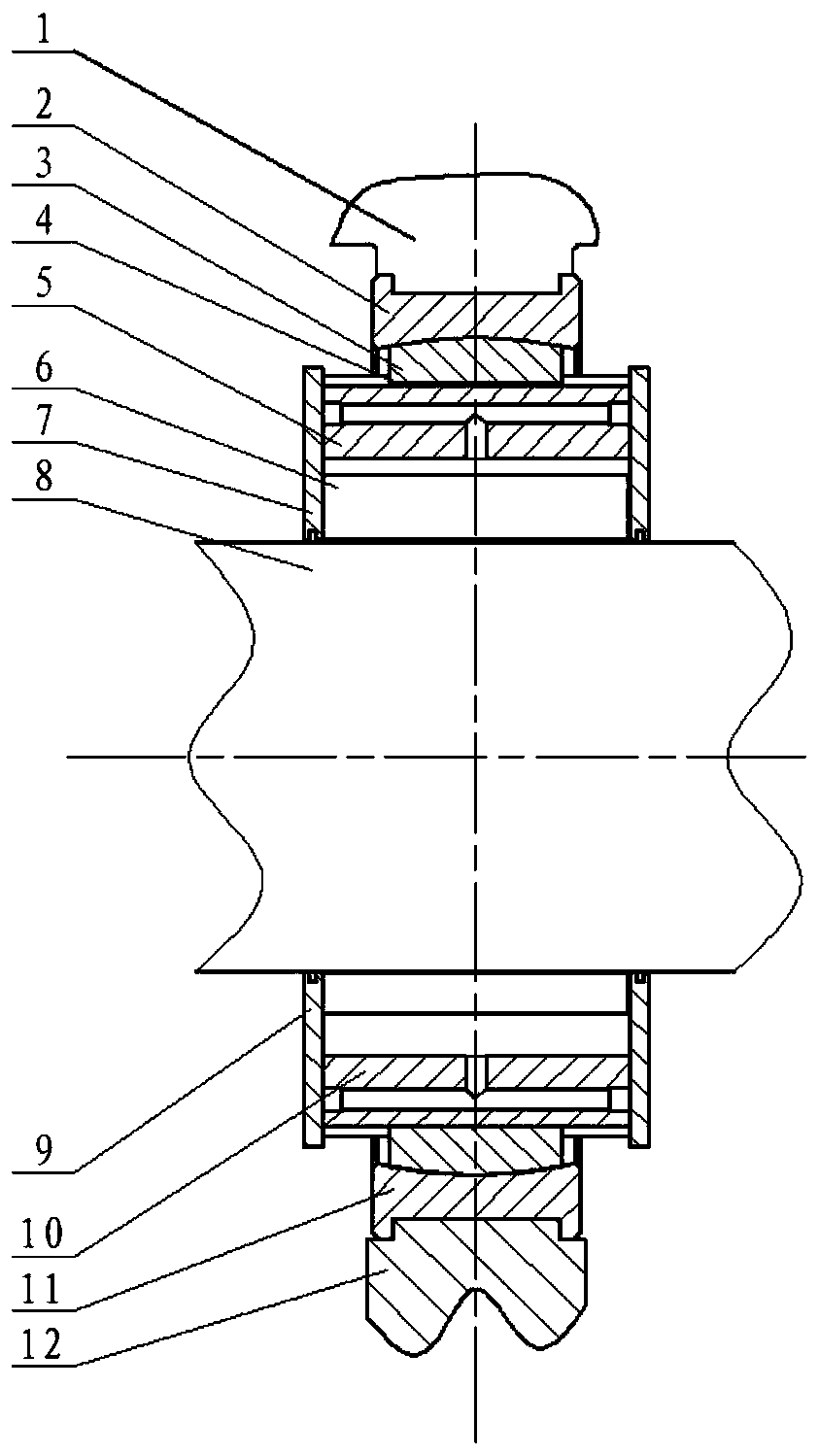

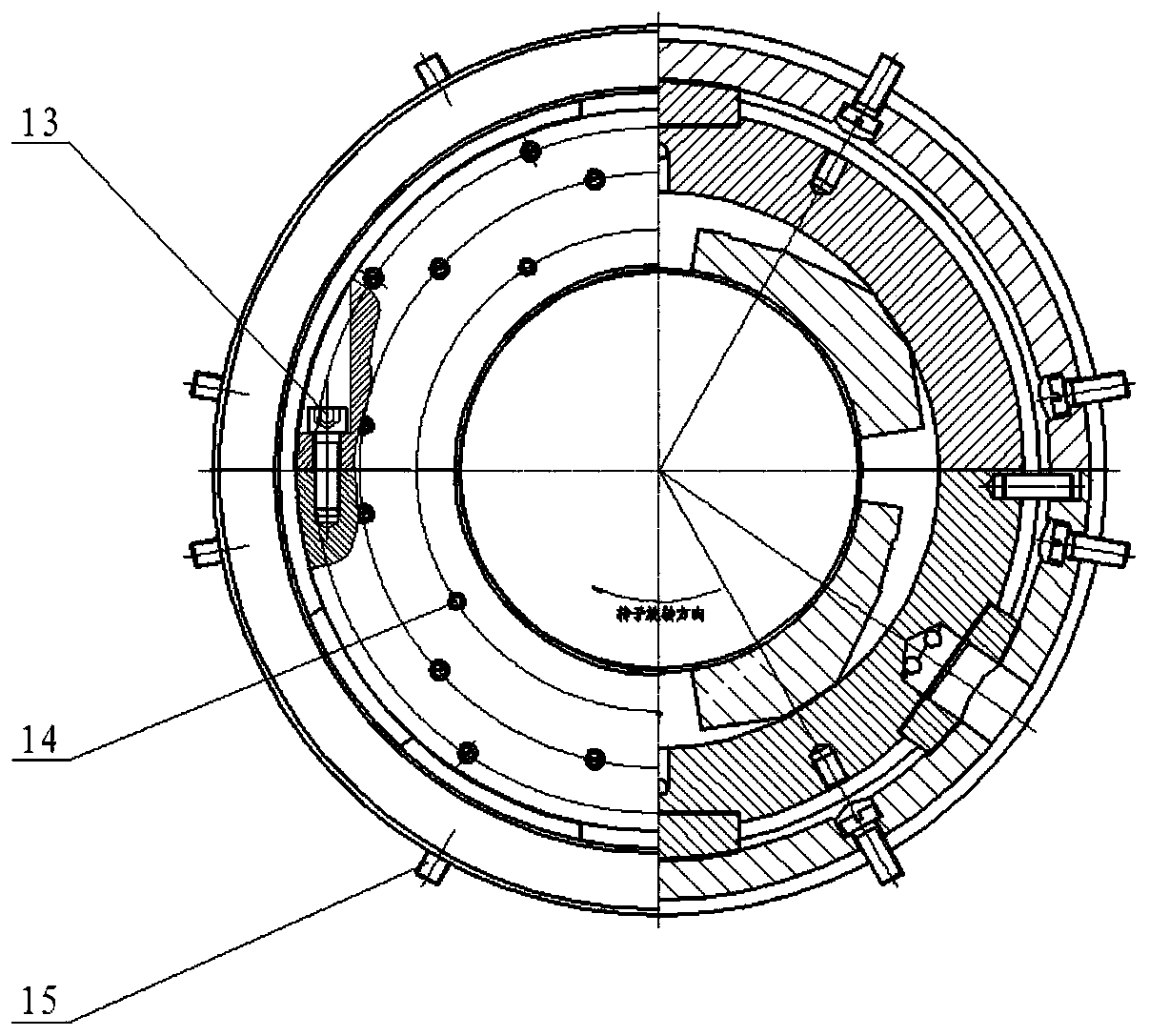

[0020] Specific implementation mode one: as figure 1 and figure 2 As shown, the self-positioning tilting pad bearing structure of the marine mobile nuclear power steam turbine in this embodiment mainly includes the upper half of the bearing housing 1, the upper half of the bearing sleeve 2, the bearing body, the upper half of the oil deflector ring 7, and the lower half of the oil deflector ring 9 , the lower half bearing housing 11, the lower half bearing housing 12, a plurality of spherical pads 3 and a plurality of tilting pads 6; the upper half bearing housing 1 and the lower half bearing housing 12 form a bearing housing, and the upper half bearing housing 2 and The lower half bearing sleeve 11 constitutes the bearing sleeve, the upper half oil deflecting ring 7 and the lower half oil deflecting ring 9 constitute the oil deflecting ring, the bearing sleeve is embedded in the bearing box, and the bearing body includes the upper half bearing body 5 and the lower half beari...

specific Embodiment approach 2

[0021] Specific implementation mode two: as figure 1 and figure 2 As shown, the number of tilting pads 6 in this embodiment is four. With this design, when the steam turbine rotor rotates, since the back arc of the tilting pad is different from the curvature of the inner arc of the bearing pad and is in line contact, the tilting pad will swing with the rotation speed of the steam turbine rotor. Due to the characteristics of the flexible rotor As well as the change of the rotor lift caused by the swaying and tilting of the hull, the tilting pad bearing contacts the spherical surface through the pad and the bearing sleeve, which can realize the axial swing of the pad. The thickness of the gasket between the bearing body and the cushion block is used to adjust the center of the steam turbine to return to the state before replacement. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0022] Specific implementation mode three: as figure 1 and figure 2 As shown, the number of spherical pads 3 in this embodiment is four. With such a design, the bearing body can be supported in the bearing sleeve by two spherical pads 3 . Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com