A method for assembling sear parts of a pistol

A sear and component technology, which is applied in the field of assembling pistol sear parts, can solve the problems of waste of previous efforts, difficult operation, and short lap length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

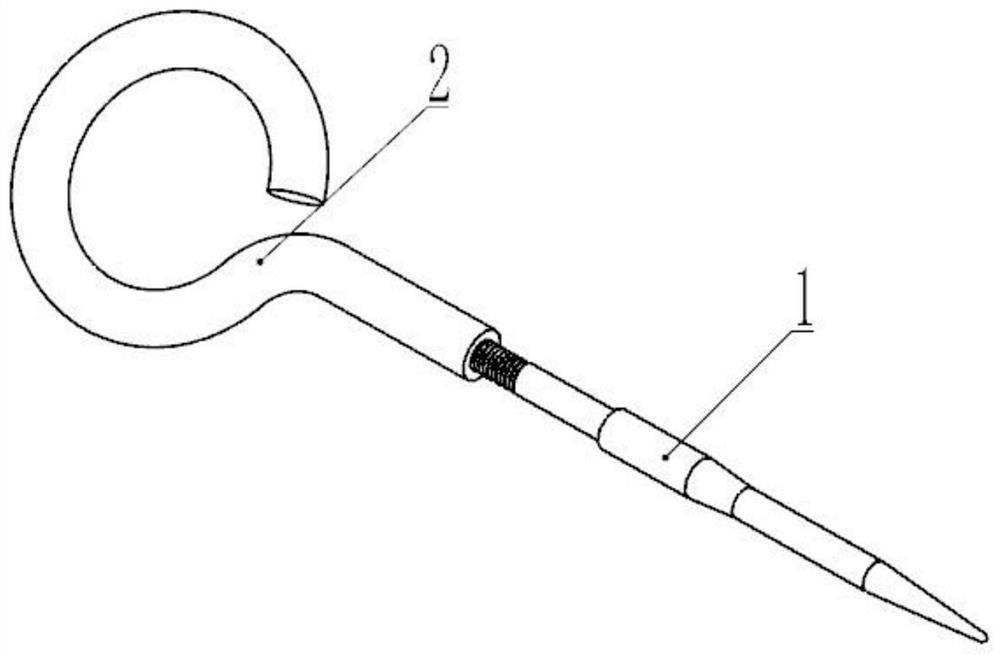

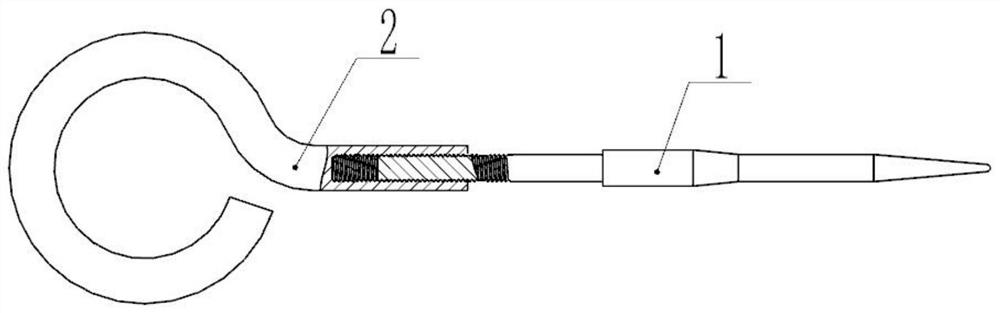

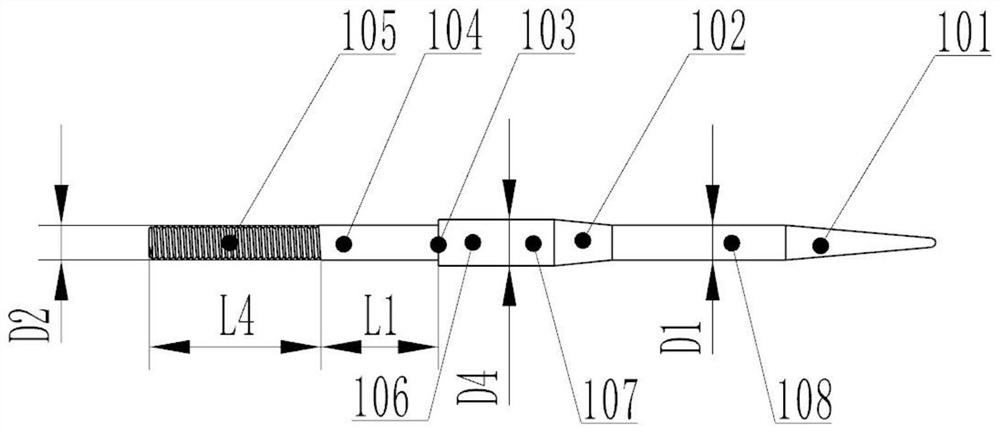

[0035] Below in conjunction with accompanying drawing, the present invention is further described, among the accompanying drawings, 1-punch body, 2-punch handle, 3-sleeve, 4-seater spring guide rod, 5-seater, 6-seater spring; 101-conical tip, 102-conical shoulder, 103-right-angled shoulder, 104-sleeve installation section, 105-thread connection section, 106-positioning section, 107-second transition section, 108-first Transition section, 201-internal thread connecting rod, 202-handle, 501-casing hole, 601-shorter spring foot of resistance spring, 602-longer spring foot of resistance spring, 603-cylindrical helix of resistance spring part.

[0036] Referring to the accompanying drawings of the description, a method for assembling a sear part of a pistol, the method includes the following steps:

[0037] S1. Prepare tools

[0038] Take the punch body 1, the punch handle 2, the casing 3, the resistance spring guide rod 4,

[0039] The punch body 1 is in the shape of a straight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com