Pin puller

A pin puller and pin shaft technology, which is applied in the field of mining auxiliary equipment and coal mine hydraulic supports, can solve the problems of large space occupied by parts, long pin length, low efficiency, etc. High efficiency and the effect of improving the safety factor of pin removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

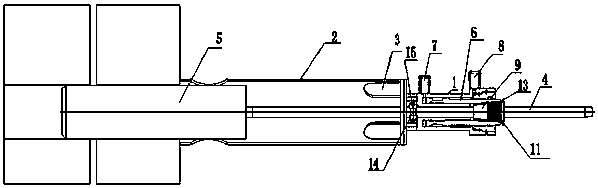

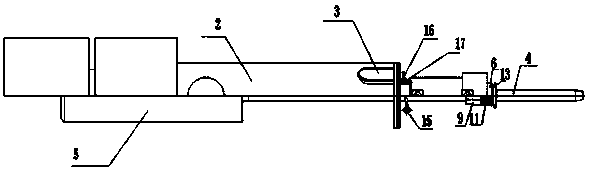

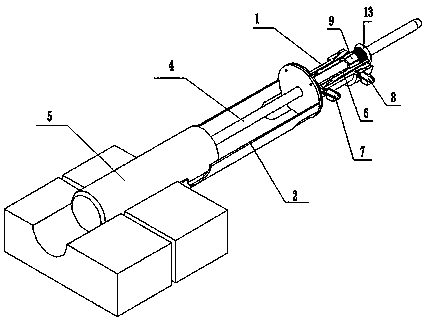

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] Such as Figure 1-10 As shown, the pin puller includes a hydraulic cylinder and a support device 2 arranged on one side of the hydraulic cylinder, and the support device 2 is fixed to one end of the cylinder body 1 of the hydraulic cylinder through a flange; the inner center of the cylinder body 1 is provided with a through hole, A tie rod shaft 4 is set inside the through hole, and the tie rod shaft 4 runs through the cylinder body 1 and penetrates the center of the support device 2 to extend into the pin shaft 5; the cylinder 1 on both sides of the through hole is provided with a piston cavity, The piston 6 is arranged in the cavity; the cylinder 1 is provided with an oil hole, and the oil hole is connected to the cavity of the piston;

[0032] The end of the piston 6 is provided with a tapered inclined surface structure on the inner wall; between the inner...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap