Sleeping berth of high-speed train

A sleeping berth and high-speed rail technology, applied in sleeping berth appliances, railway car body parts, transportation and packaging, etc., can solve the problems of low comfort for passengers and inconvenient getting on and off the sleeper, and achieve high comfort and increase the anti-theft function Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

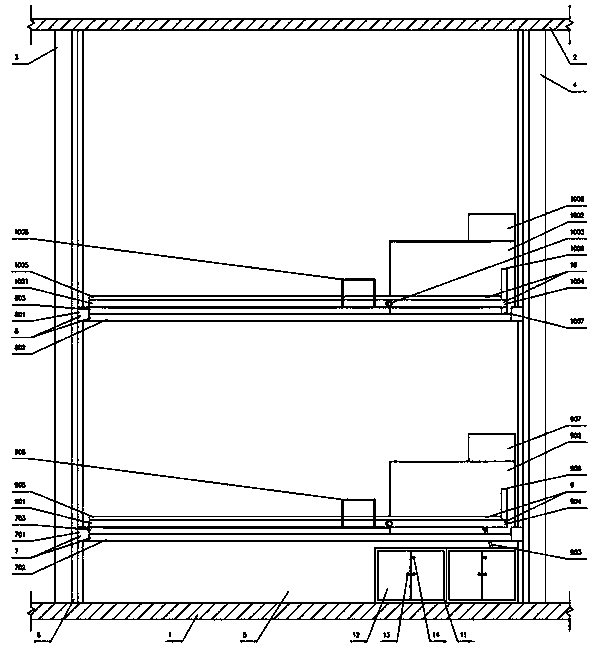

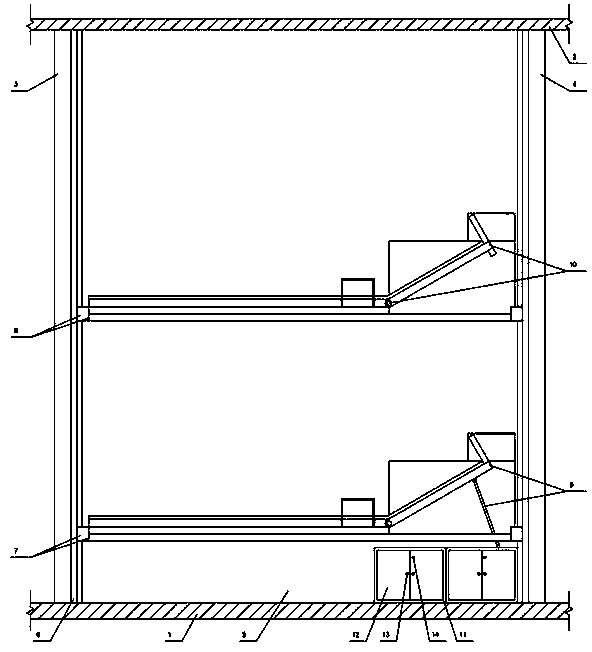

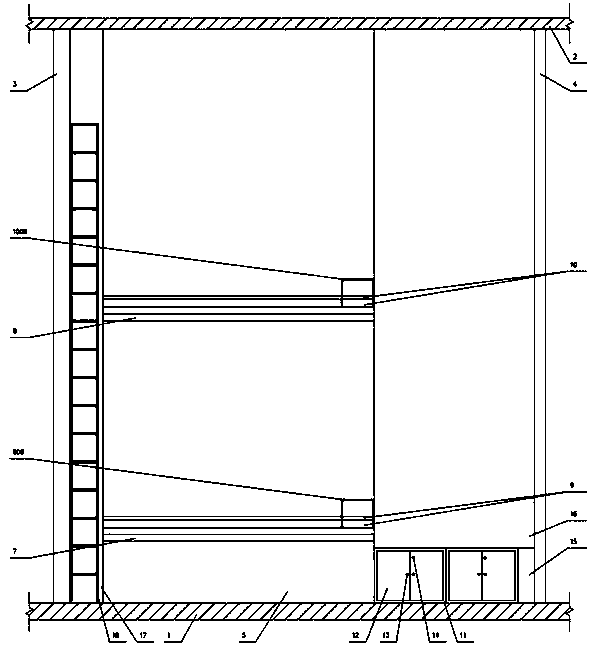

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] refer to Figure 1-3, a high-speed rail sleeper described in this specific embodiment, comprising a compartment floor 1, a compartment top 2, a partition A3, a partition B4, a compartment side wall 5, a linear motor guide rail 6, a lift assembly A7, a lift assembly B8, and a sleeper assembly A9, the sleeper component B10, the lower ends of the partition A3 and the partition B4 are respectively fixedly connected with the compartment floor 1, the partition A3 is located at the front side of the partition B4, and the right side walls of the partition A3 and the partition B4 are respectively connected to The compartment side wall 5 is fixedly connected, and the upper ends of the partition A3 and the partition B4 are respectively fixedly connected with the top 2 of the compartment. The space surrounded by the partition A3 and the partition B4 is diagon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com