Flexible packaging container for liquid-state materials

A flexible packaging and material technology, applied in the direction of containers, packaging, flexible containers, etc., can solve the problems of consuming resources and components, difficult to use the filling tube space, and many manufacturing steps, and achieve effective use of space and structural design. Ingenious, resource-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

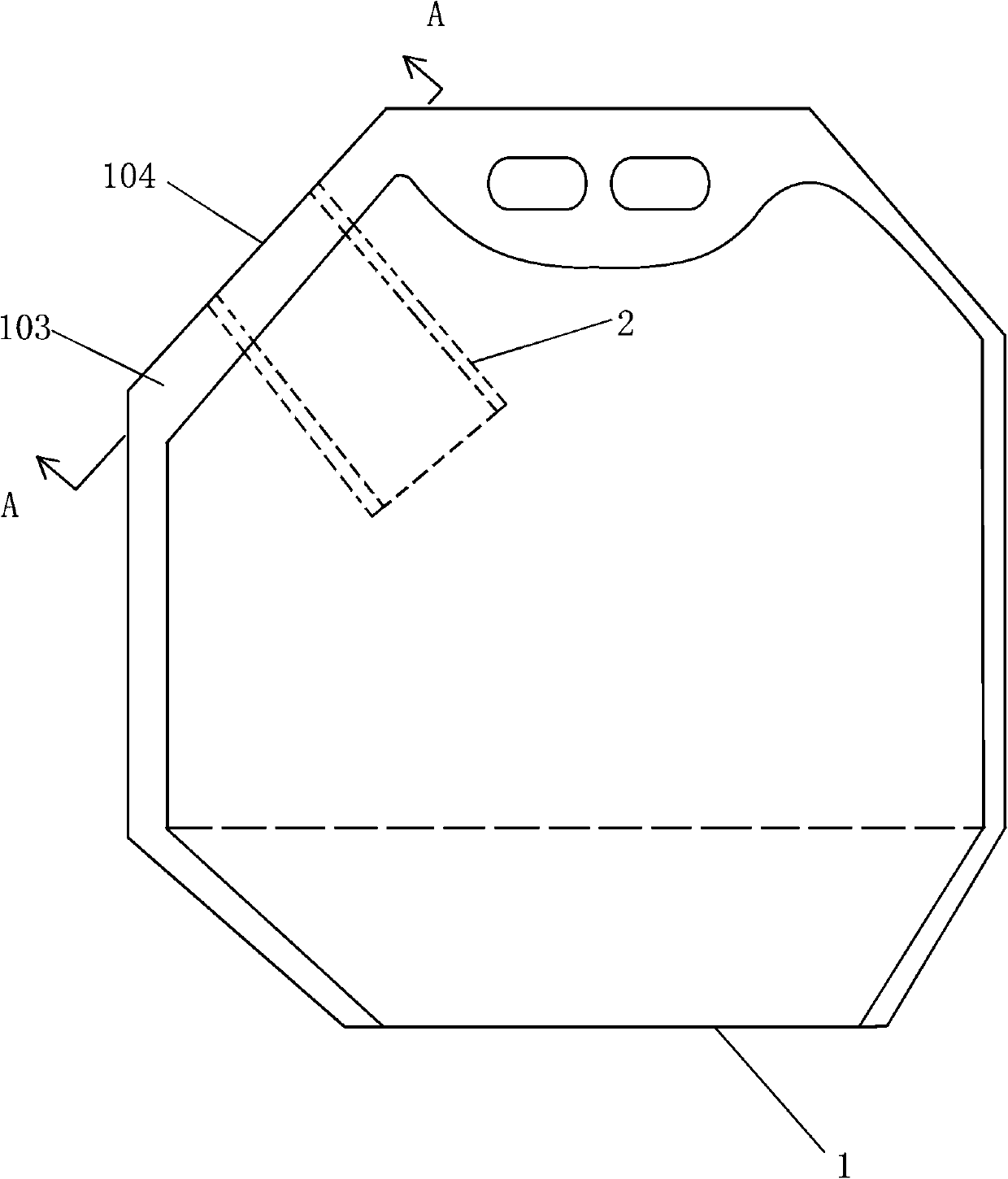

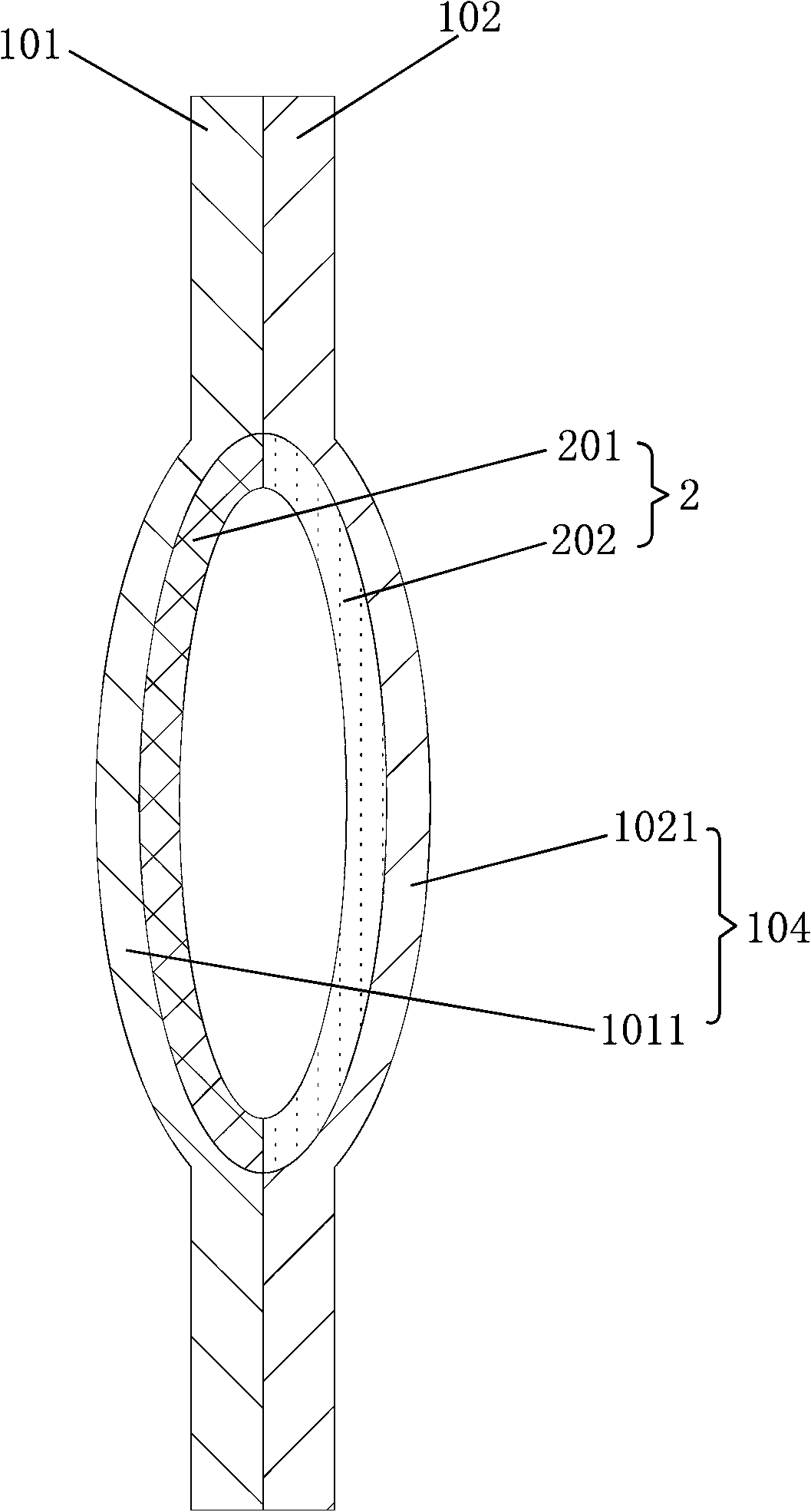

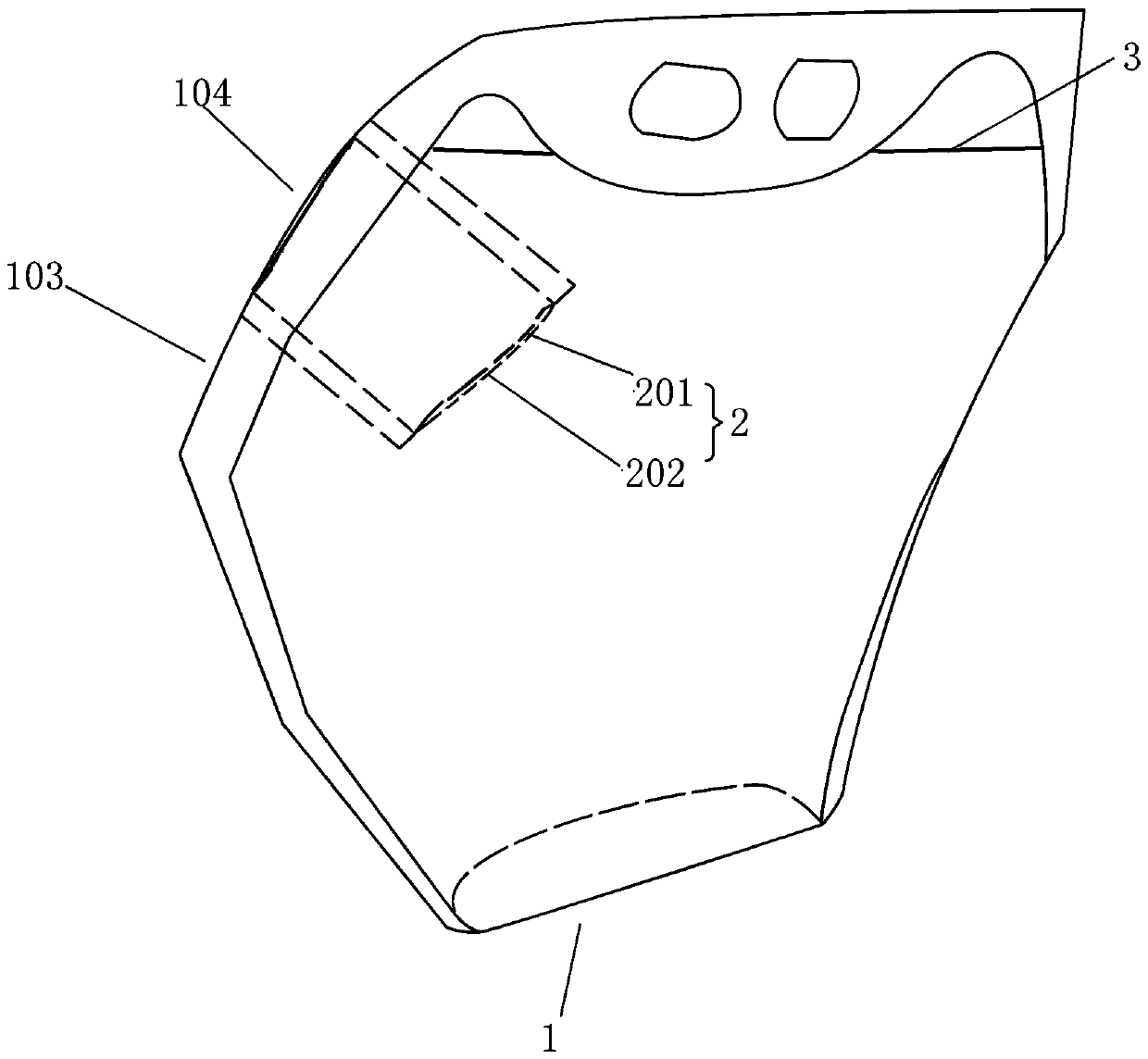

[0019] Such as Figure 1-4 As shown, the flexible packaging container for liquid materials in this embodiment includes a bag body 1 and a multifunctional tube. The bag body 1 has a filling port 103. The multifunctional tube is a film sleeve 2 and a film sleeve 2. The fixed end 203 is connected to the filling port of the bag body 1. In the initial state, the film sleeve 2 is located in the bag body 1. When the liquid material is filled with the bag body 1, the film sleeve 2 is squeezed into a sheet by the liquid material and the filling port It is sealed, and the film sleeve 2 is turned inside and out and extends out of the bag body 1 when it is poured.

[0020] The film sleeve 2 is composed of a first film sheet 201 and a second film sheet 202. The top of the inner side wall of the first film sheet 201 and the top of the inner side wall of the second film sheet 202 are connected together. The bottoms of the inner side walls of the second film sheet 202 are connected together to ...

Embodiment 2

[0028] Such as Figure 5 As shown, the difference between the flexible packaging container for liquid materials in this embodiment and Embodiment 1 is:

[0029] The inner wall of the film sleeve 2 is provided with a turning auxiliary pull tab 4, the rear end of the turning auxiliary pull tab 4 is connected to the outlet 204 of the film sleeve 2, and the front end of the turning auxiliary pull tab 4 is located at the filling port 104 of the bag body 1. In other words, the front end of the auxiliary turning pull tab 4 does not exceed the filling opening 104 of the bag body 1, so as to prevent the front end of the turning auxiliary pull 4 from being unintentionally pulled and causing liquid leakage.

[0030] In this way, the film sleeve 2 can be taken out quickly and conveniently by dragging the front end of the flip auxiliary pull tab 4 during dumping, and the inside and outside of the film sleeve 2 can be flipped, which is more convenient and quick to use.

[0031] The wall thickness ...

Embodiment 3

[0034] The difference between the flexible packaging container for liquid materials in this embodiment and Embodiment 1 is:

[0035] The wall thickness of the film sleeve 2 is 0.02 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com