Glass pipe overflow down-draw molding apparatus and design method thereof

A glass tube and overflow technology, applied in glass molding, glass molding, glass manufacturing equipment, etc., to achieve the effects of small thickness deviation, excellent surface quality, and good surface characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

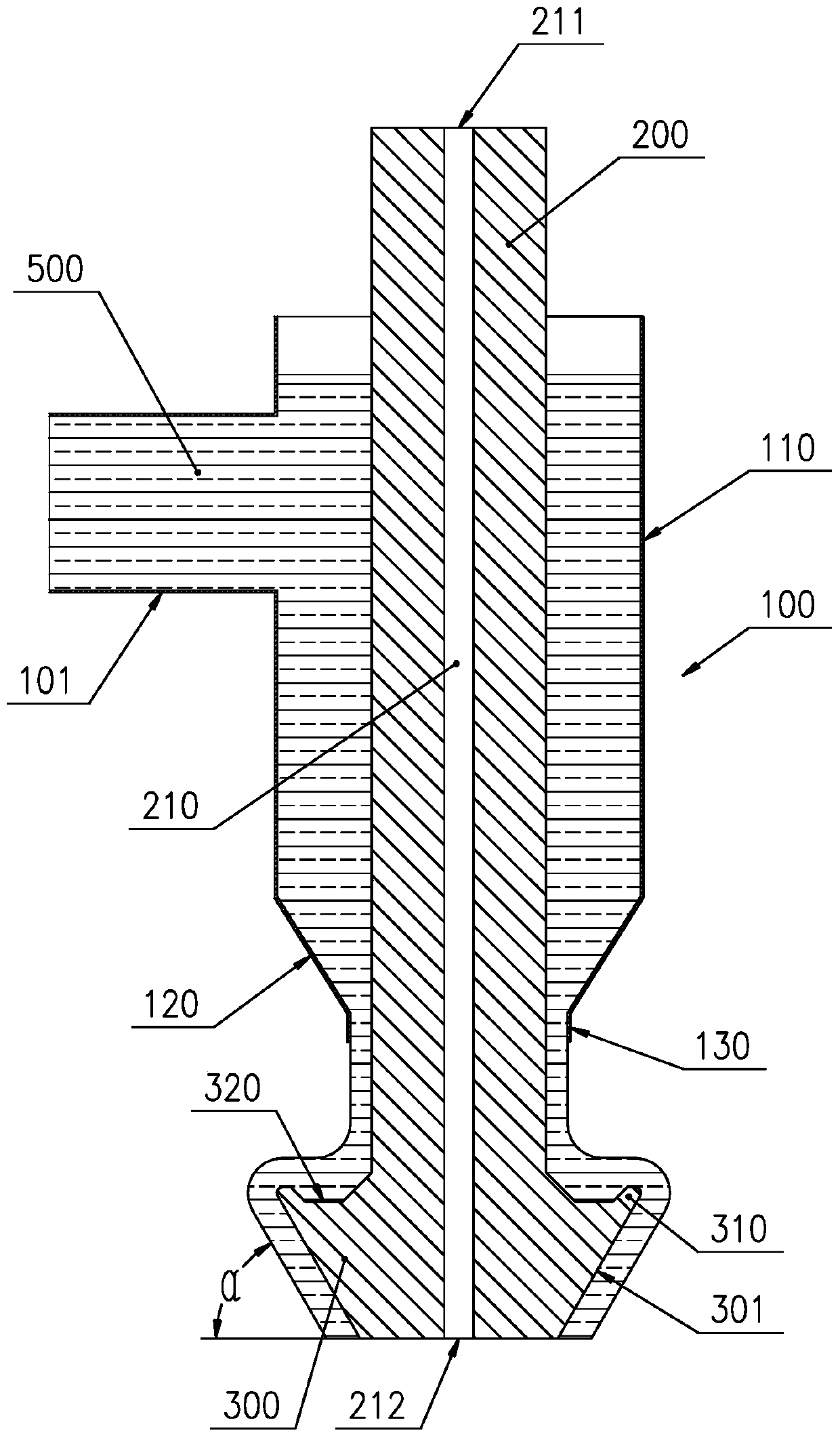

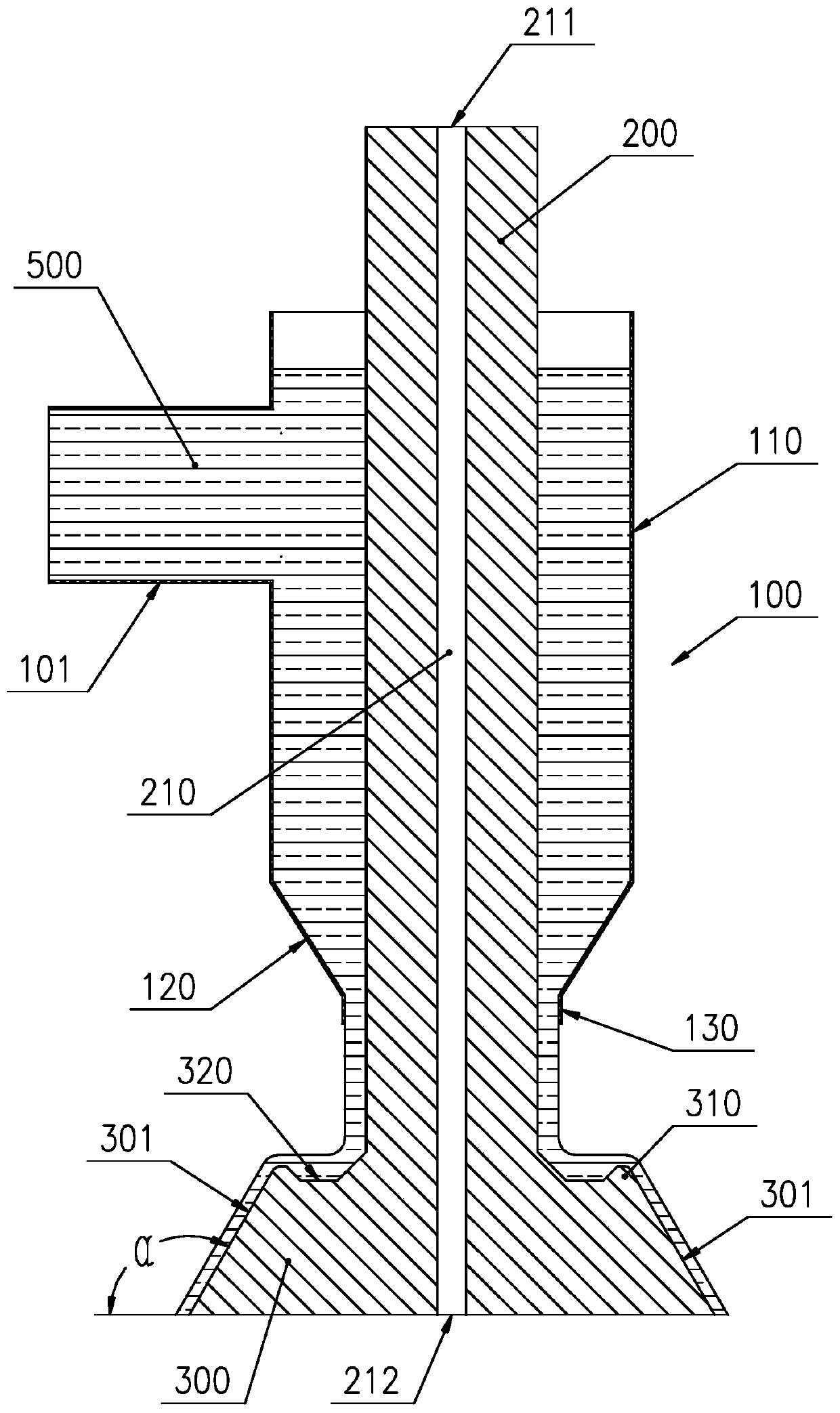

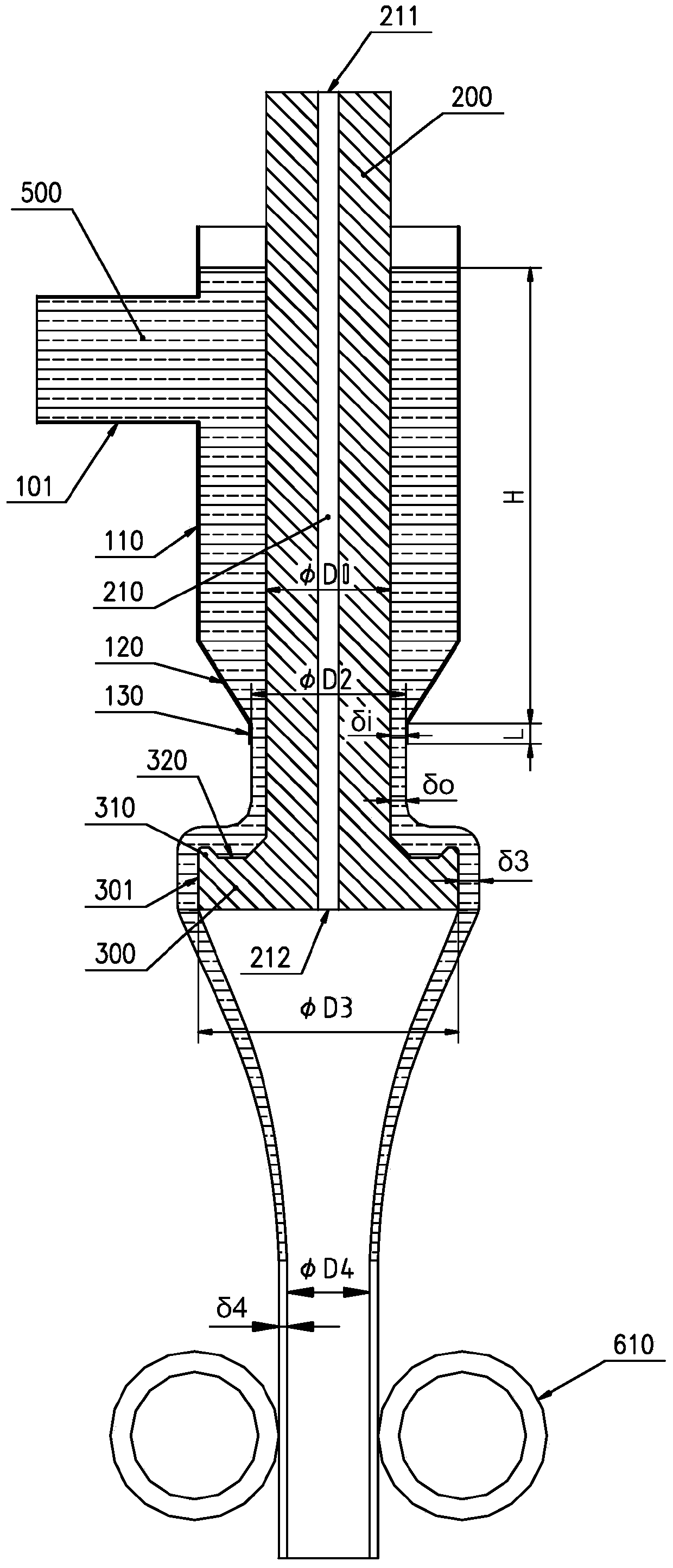

[0114] The size parameters and physical simulation experiment test parameters of an overflow glass tube overflow down-draw forming device are shown in Table 1. The viscosity of glass molding is simulated with high-viscosity silicone oil, and the experimental results are shown in 2. The glass tube overflow down-draw forming device is used to make a glass tube with a diameter of 6.0505 cm and a tube thickness of 0.1 cm; the shrinkage ratio of the tube diameter is D 3 / D 4 is 2.85.

[0115] Table 1: Adoption image 3 The design data of the structural form for simulation experiments

[0116]

[0117] Table 2: Adoption image 3 The liquid film thickness and thickness deviation test data of the simulation experiment

[0118] Numbering 1 2 3 4 5 6 7 8 Thickness (mm) 2.96 3.09 3.05 2.9 2.92 3.09 2.98 2.96 Relative deviation -1.13% 3.22% 1.88% -3.13% -2.46% 3.22% -0.46% -1.13%

[0119] During the experiment, the outlet at the lowe...

Embodiment 2

[0125] The size parameters and physical simulation test parameters of an overflow down-draw forming device for an inner overflow glass tube are shown in Table 3. The viscosity of glass molding was simulated with high-viscosity silicone oil, and the experimental results are shown in Table 4. The glass tube overflow down-draw forming device is used to make a glass tube with a diameter of 4.2266 cm and a tube thickness of 0.1 cm; the shrinkage ratio of the tube diameter is D 3 / D 4 is 3.35.

[0126] Table 3: Adoption Image 6 The design data of the structural form for simulation experiments

[0127]

[0128] Table 4: Adoption Image 6 The liquid film thickness and thickness deviation test data of the simulation experiment

[0129] Numbering 1 2 3 4 5 6 7 8 Thickness (mm) 3.71 3.70 3.59 3.73 3.58 3.64 3.53 3.51 Relative deviation 2.47% 2.03% -0.88% 2.83% -1.09% 0.37% -2.59% -3.15%

[0130] During the experiment, the outlet of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap