Fabricated building large roof anti-seismic joint, roof system and construction method of roof system

A prefabricated, large-scale technology, applied in buildings, building components, building structures, etc., can solve the problems of poor seismic performance of node structures, installation nodes cannot be fine-tuned, and installation is inconvenient, etc., to achieve outstanding seismic effects and wide range of use. , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

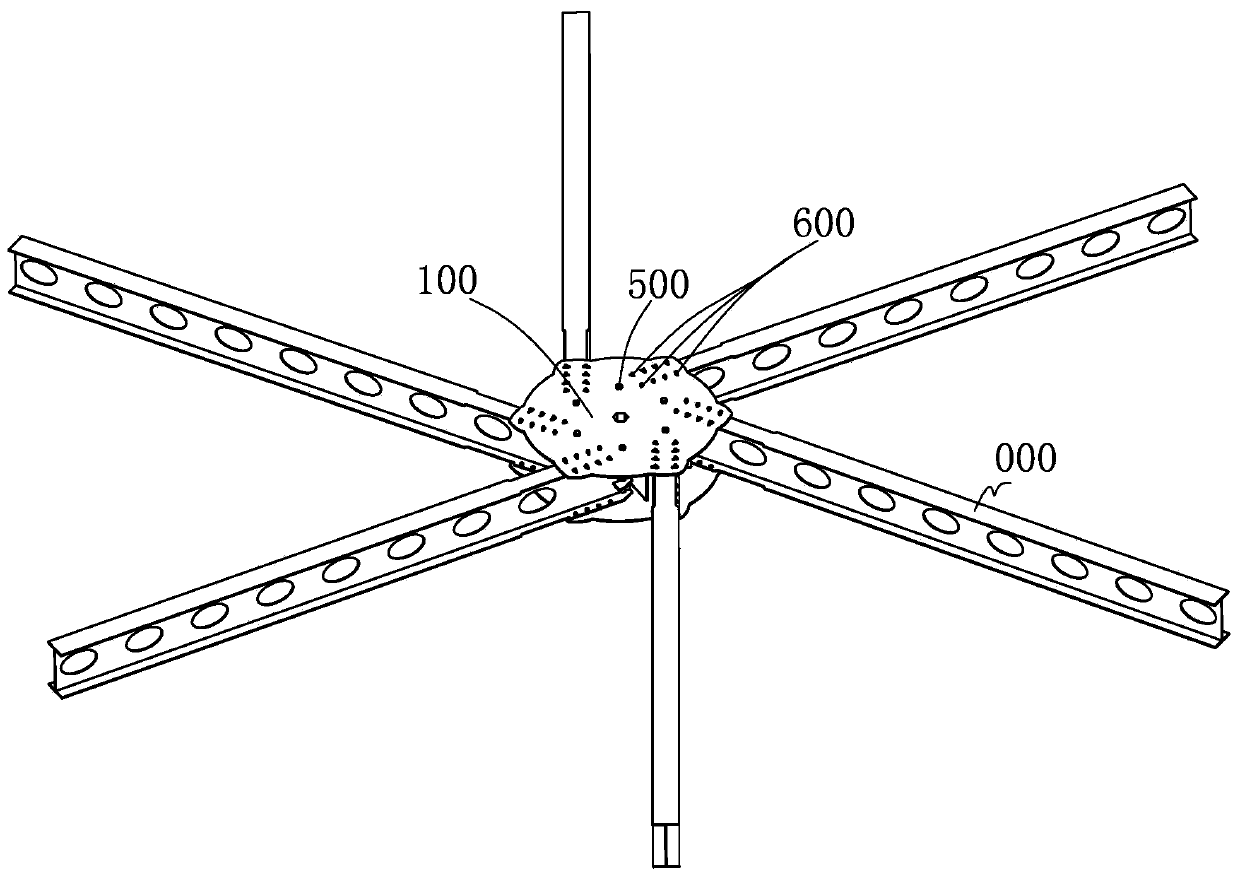

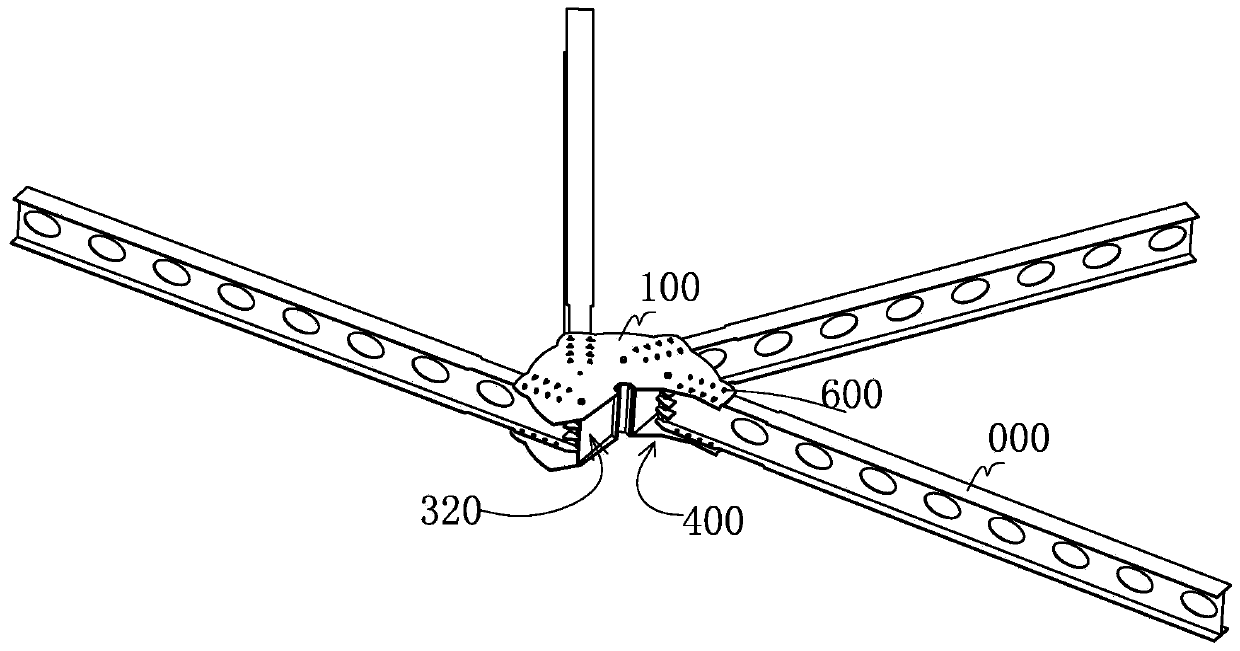

[0062] refer to Figure 1 to Figure 8 , this series of drawings, for certain reasons, such as the clear expression of engineering views, individual details in the drawings have been omitted, the omission is based on the requirement of clear expression, and the omission will not affect professional Skilled persons should be allowed to reproduce this embodiment. To take a step back, due to the differences in the understanding ability of technicians, even if there are things that are not easy to understand, please bear with us.

[0063] exist figure 1 In , an example of a node is given, figure 2 , in order to give a detailed example of the internal combination state of the node, an example is given in this figure by partial dissection and partial omission. In this example, the missing part does not exist in reality, just A way to express the internal structure is just an example, please give me a correct understanding.

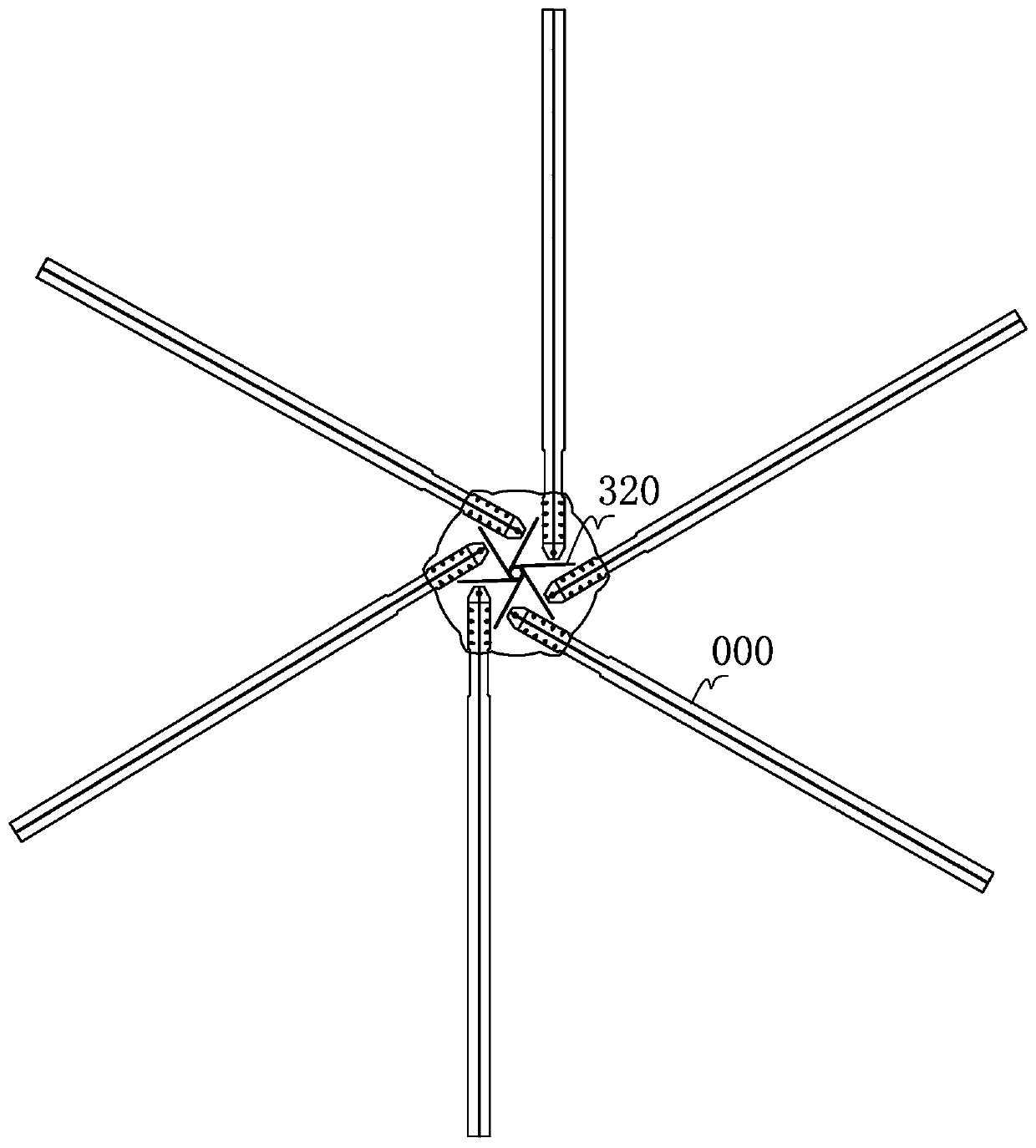

[0064] image 3 In , it is given in a top view state,...

Embodiment 2

[0087] refer to Figure 10 , in this embodiment, the innovation lies in the setting of the plastic weak zone on the steel beam. In this embodiment, the steel beam is divided into two groups, and the strength of the plastic weak zone 005 in each group is different and arranged at intervals. That is to say, some plastic weak areas have better plasticity, and some have poorer plasticity. When a strong earthquake occurs, the steel beams in the plastic weak areas can be deformed according to the set order, and the seismic performance of the building can be improved.

Embodiment 3

[0089] As a supplementary description to Embodiment 1, in fact, in the present invention, the number of steel beams corresponding to each group of connection plate assemblies can be six groups in Embodiment 1, or other numbers, such as 8 groups, 12 groups etc. Usually, the number is greater than 3, that is to say, it is used to complete the connection of more than three sets of steel beams. Of course, multiple or multiple groups of steel beams are evenly arranged in the circumferential direction of the connection plate assembly and arranged along the direction.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap