Limiting and contraction distortion compensating plate spring pre-tightening structure for pressure-resistant body of deep sea submersible vehicle

A technology of shrinkage deformation and pressure-resistant structure, which is applied in the direction of leaf spring, spring/shock absorber, mechanical equipment, etc., can solve the problem of unfavorable ultimate bearing capacity of pressure-resistant body, and achieve the reduction of structural failure risk, compact structure, fast The effect of disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be described below in conjunction with the drawings.

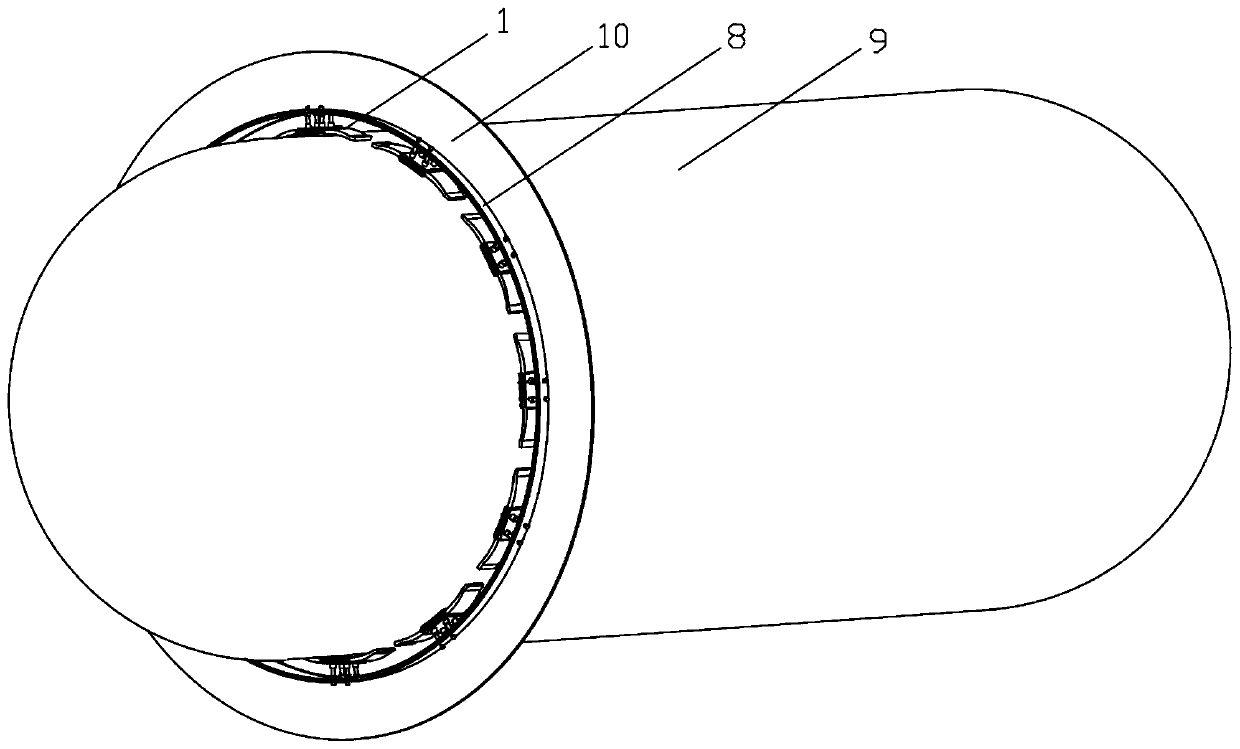

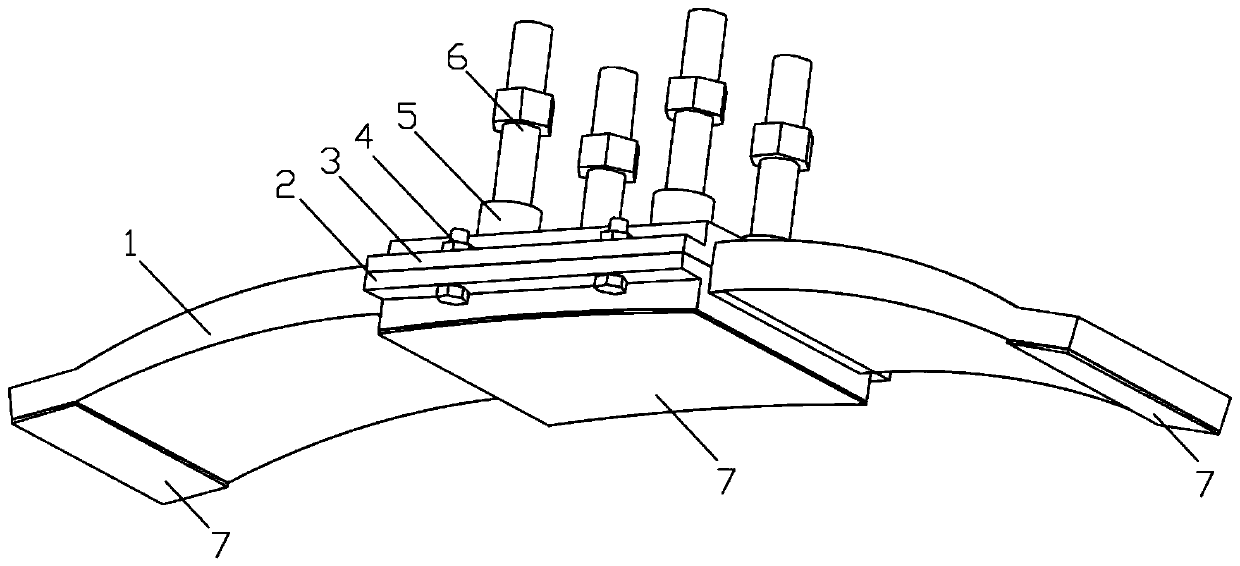

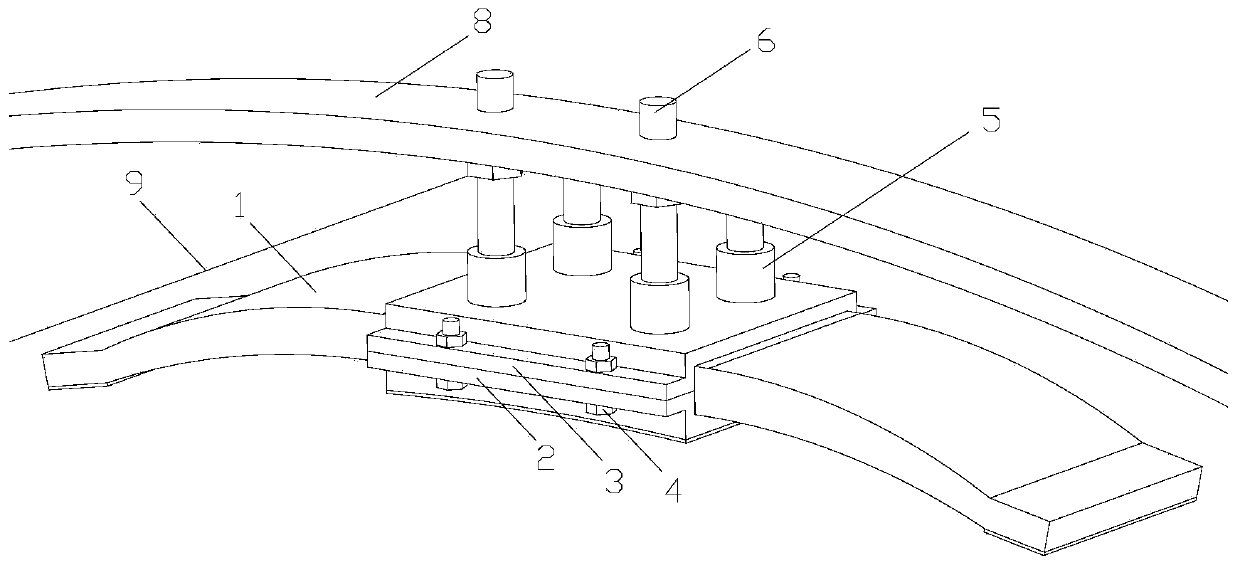

[0025] Such as figure 1 , figure 2 with image 3 As shown, the plate spring pre-tensioning structure of the pressure-resistant body of the deep-sea submersible in this embodiment includes a pressure-resistant body 9, and the outer circumferential surface of the pressure-resistant body 9 and its spacer are sheathed with a non-pressure-resistant structure 10, One end of the non-pressure-resistant structure 10 extends the non-pressure-resistant structure inner panel 8. The non-pressure-resistant structure inner panel 8 is parallel to the outer surface of the pressure-resistant body 9; on the outer circumferential surface of the pressure-resistant body 9 and the non-pressure-resistant structure inner panel 8 There are multiple sets of pre-tightened assemblies installed between.

[0026] The structure of the single-group pre-tightening assembly is as follows: It include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com