System with lubricating oil circuit and cooling oil circuit

A technology of lubricating oil and cooling oil, applied in the direction of gear lubrication/cooling, lubricating parts, engine lubrication, etc., can solve the problems of occupying space, space consumption, expensive, etc., to reduce parts, reduce weight, and improve oil circuit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

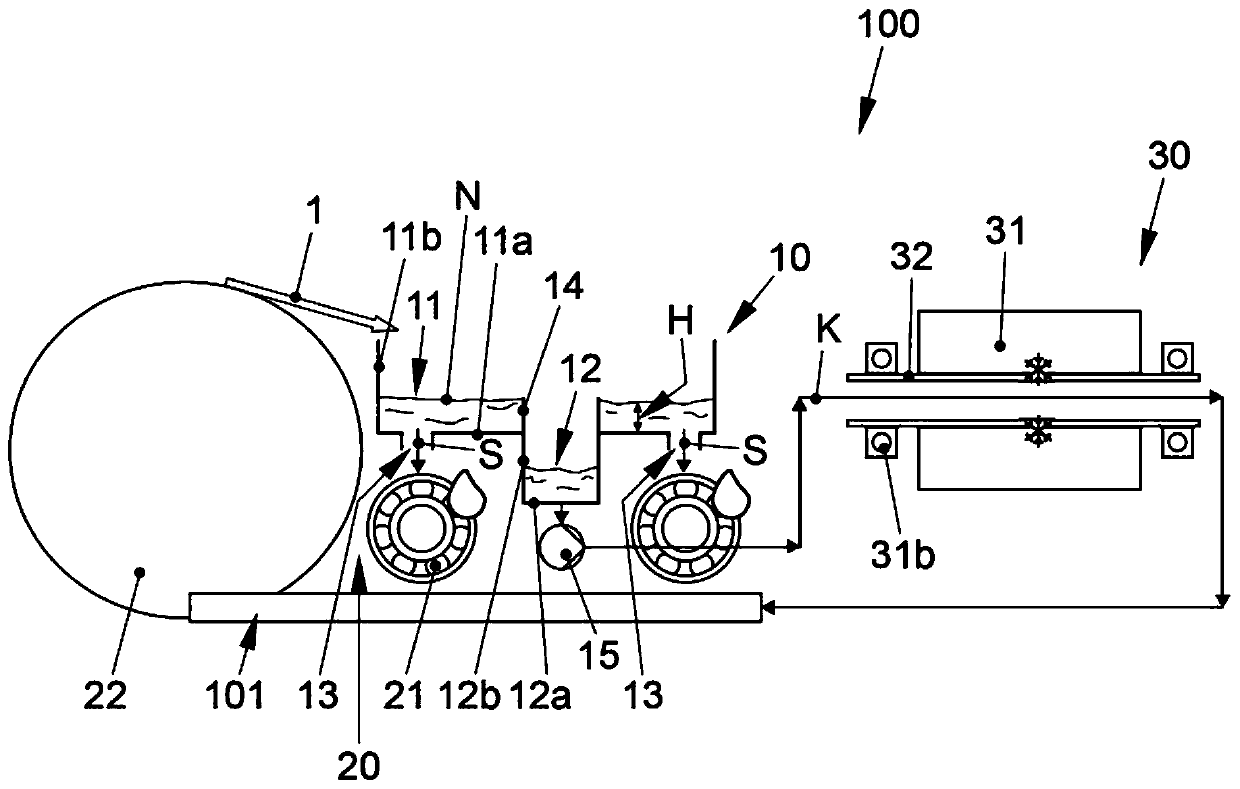

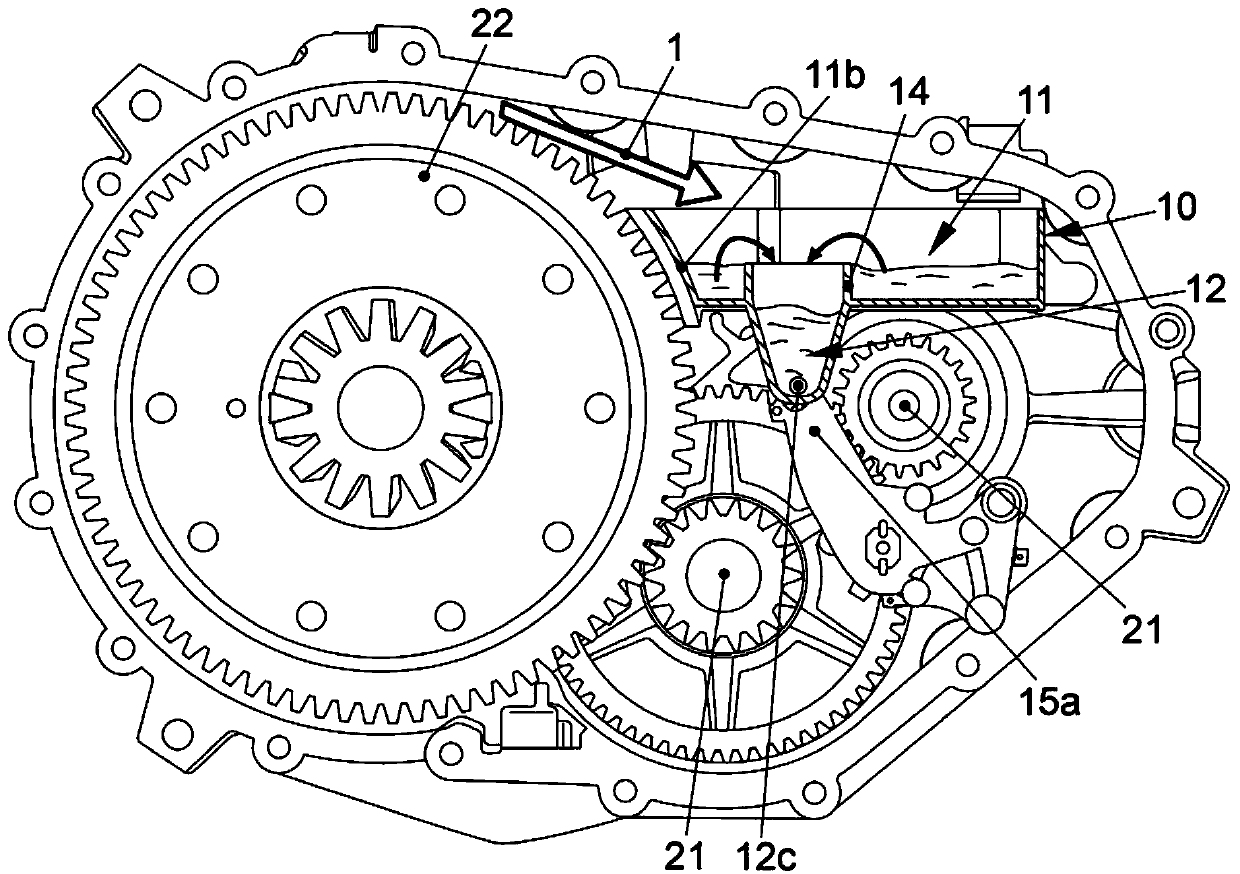

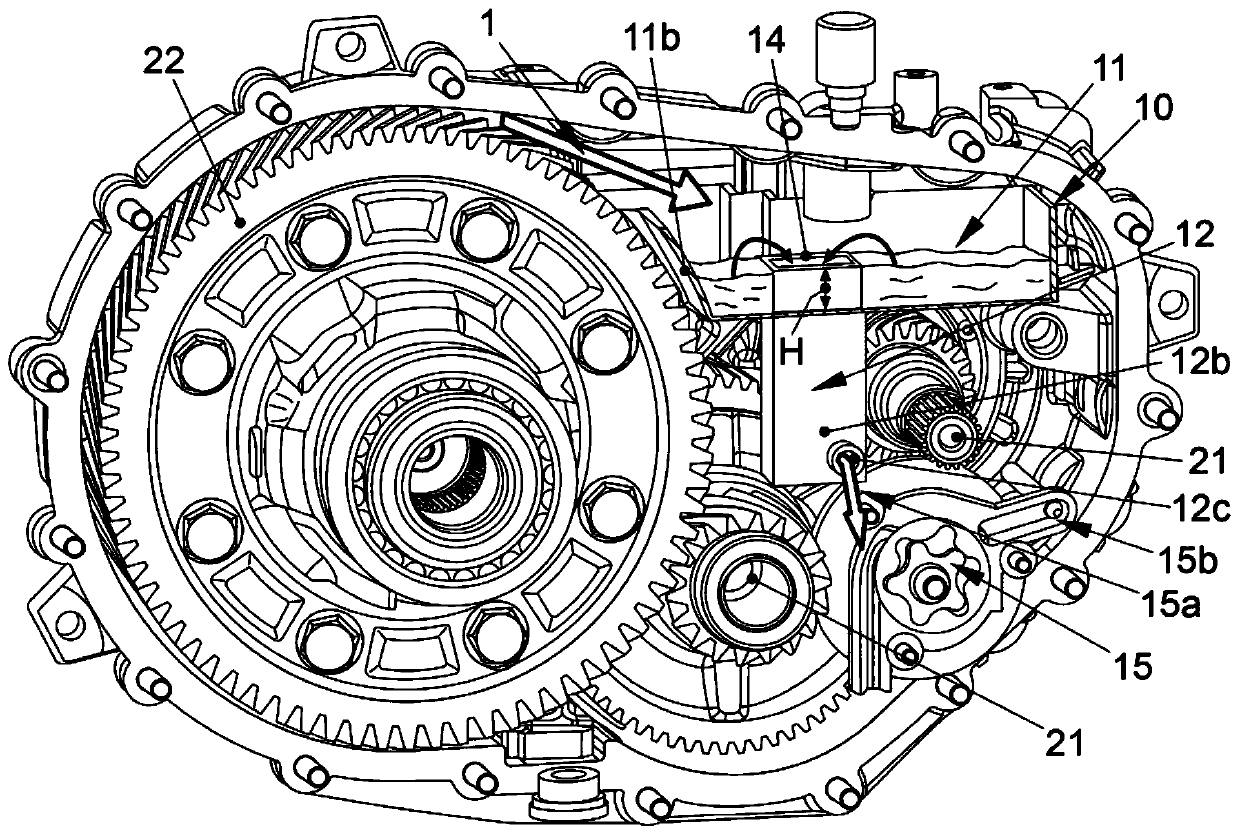

[0046] figure 1 Shown is an embodiment of a system 100 according to the invention, for example a vehicle drive train, comprising a transmission 20 with bearings lubricated by a lubricating oil circuit S, in particular a transmission bearing 21, and a rotor with cooling by a cooling oil circuit K 31 of the motor 30 and an embodiment of the oil reservoir 10 according to the invention, and figure 1 The principle of the distribution of oil according to the invention into the lubricating oil circuit S and the cooling oil circuit K and the principle of the oil delivery according to the invention are shown.

[0047] figure 1 It is shown that the oil reservoir 10 is designed to distribute the oil 1 into the lubricating oil circuit S and the cooling oil circuit K. In this case, the oil reservoir 10 preferentially supplies the lubricating oil circuit S with oil 1 . To this end, the oil reservoir 10 has a first oil reservoir 11 for supplying oil to the lubricating oil circuit S and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com