Threaded valve cover sealing structure with plane elastic sealing groove

A technology of elastic sealing and sealing structure, applied in the direction of valve shell structure, valve lift, valve details, etc., can solve the problems of weld stress increase, unfavorable valve sealing, failure and other problems, so as to reduce the deflection and benefit the valve disc Effect of sealing and reducing the length of the cantilever beam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the application is further described:

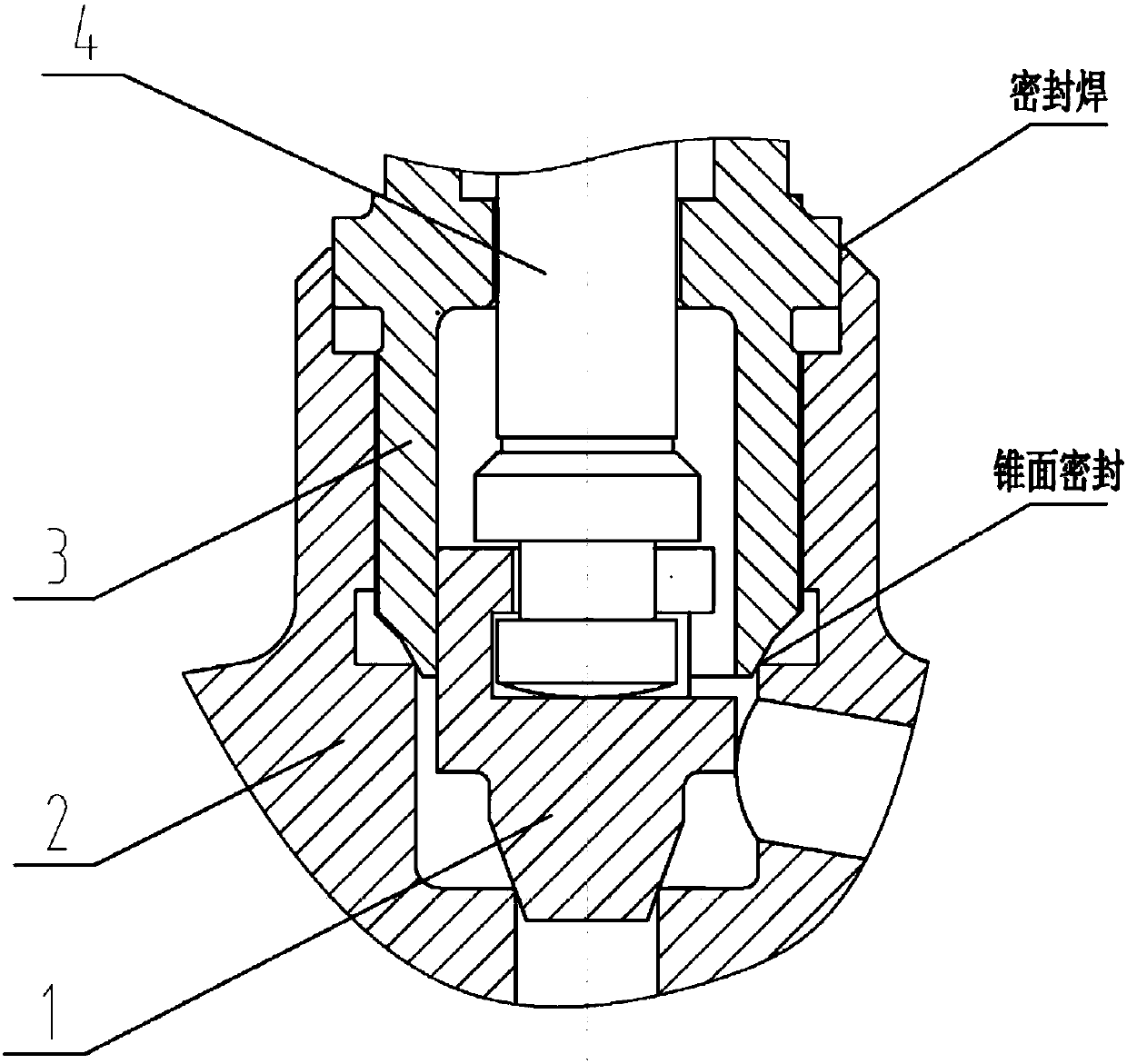

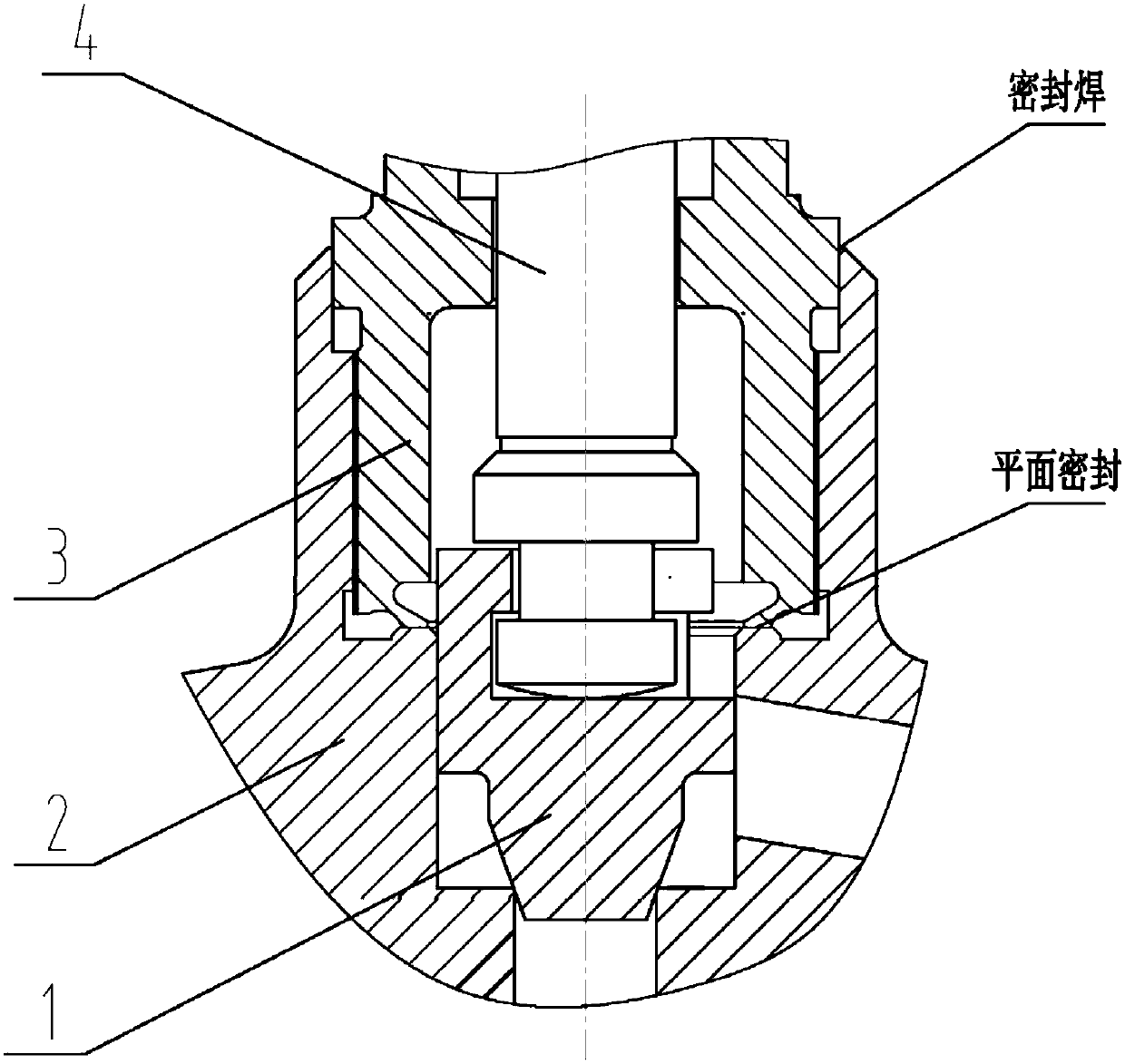

[0014] as attached figure 2 As shown, a threaded bonnet sealing structure with a planar elastic sealing groove, wherein the bottom of the bonnet is designed as a plane, which forms a plane seal with the corresponding plane of the valve body, and a groove similar to the shape of Ω is designed at the plane seal of the bonnet , and process a concave arc on the opposite side of the groove, so that an elastic Ω-shaped groove is formed. The outer circle of the valve clack is guided with the inner hole of the valve body, and the diameter of the inner hole of the valve cover is 0.5-1mm larger than the outer circle of the valve disc.

[0015] The technical features of the present invention are as follows: since the flat seal of the bonnet is designed as an elastic Ω-shaped groove, the elastic groove will automatically compensate for the thread relaxation under temperature and pressure chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com