A fastened steel sleeve for the exhaust pipe of low-temperature refrigeration equipment

A refrigeration equipment, fastening technology, applied in mechanical equipment, sleeve/socket connections, pipes/pipe joints/pipe fittings, etc., can solve the problem of steel sleeves not being firmly fixed, so as to avoid weak fixing and reasonable structure setting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

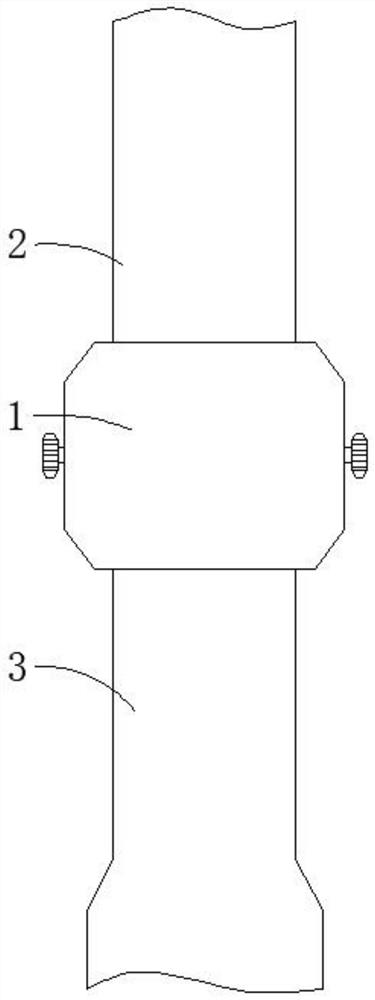

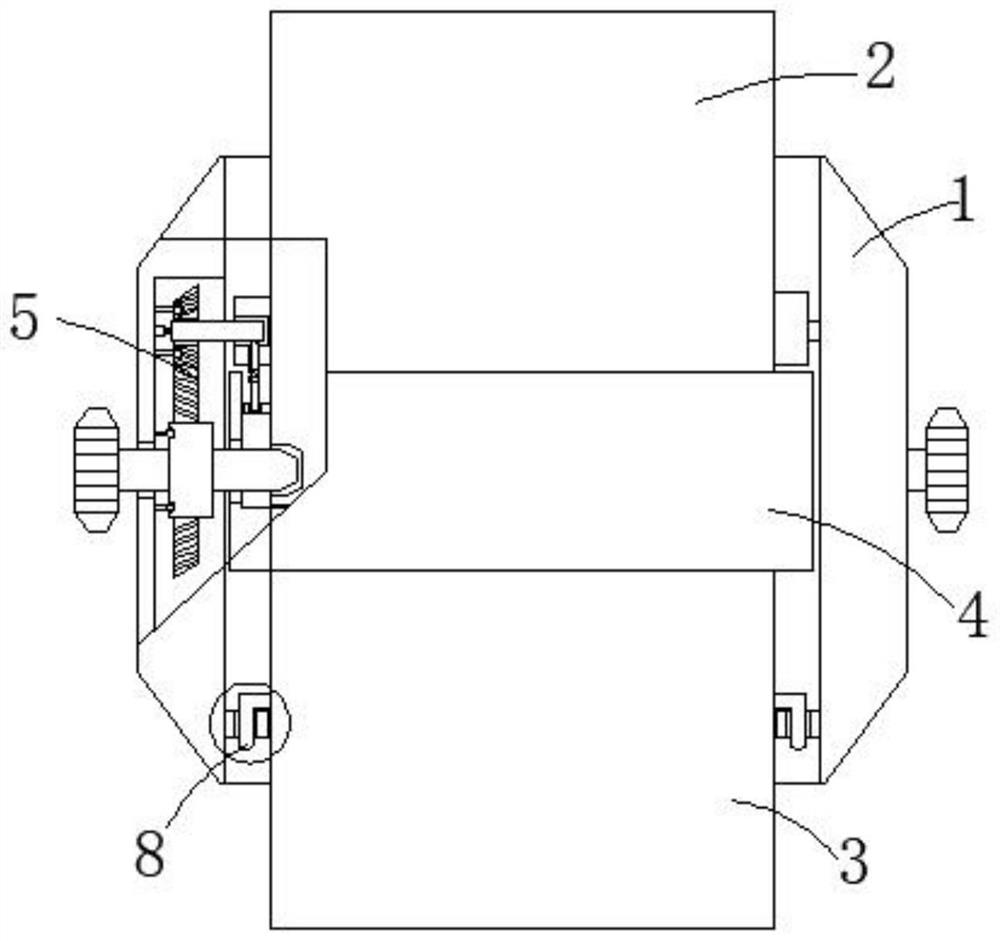

[0030] Attached below Figure 1-7 The present invention is further described with embodiment:

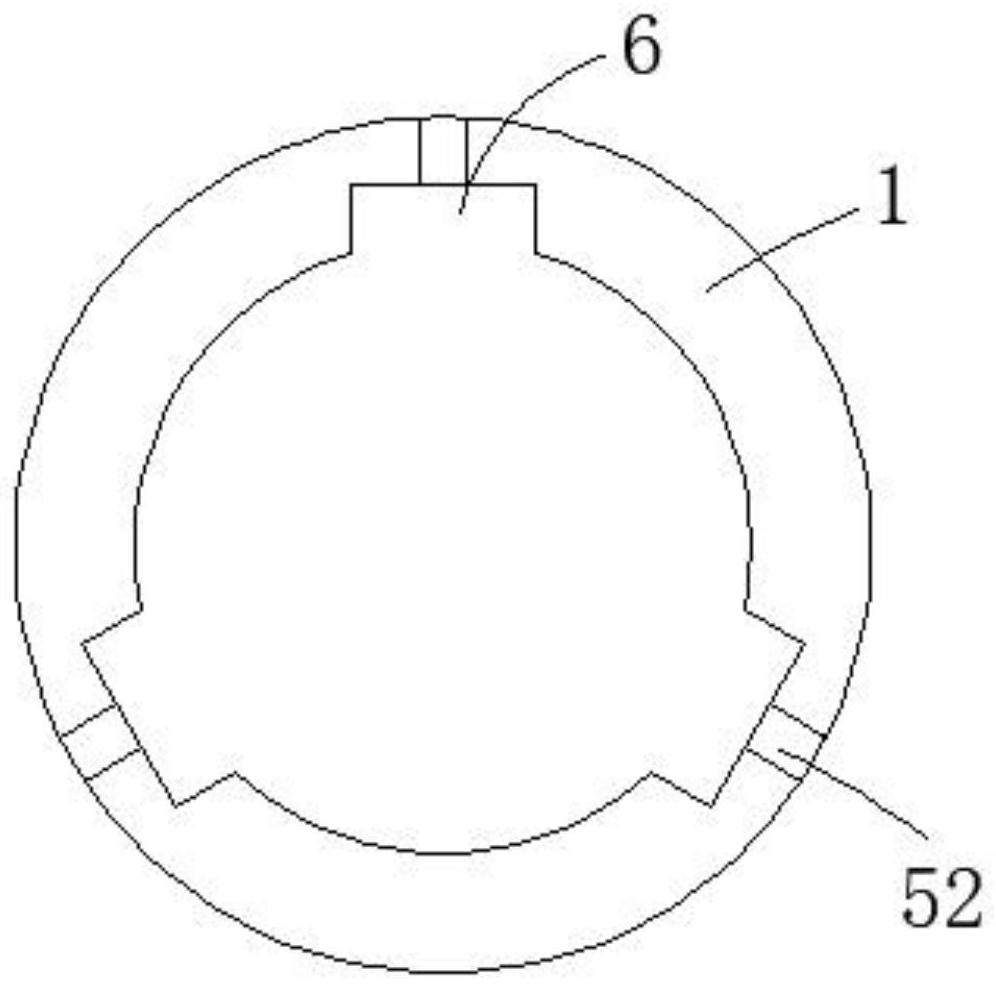

[0031] A fastened steel sleeve for the exhaust pipe of low-temperature refrigeration equipment, comprising a steel sleeve 1, an upper steel pipe 2, a lower steel pipe 3 and a sealing ring 4, the steel sleeve 1 is movably set outside the upper steel pipe 2 and the lower steel pipe 3, and the sealing ring 4 The fixed sleeve is arranged outside the lower steel pipe 3, and the seal ring 4 is movably arranged outside the upper steel pipe 2. The steel sleeve 1 is provided with a fixed assembly 5, which includes a fixed screw 51 and a first threaded hole 52. The first threaded hole 52 is set On the steel sleeve 1, the fixing screw 51 is screwed in the first threaded hole 52, and the fixing screw 51 is threadedly connected with the second threaded hole 53 provided on the sealing ring 4, and the tip of the fixing screw 51 extends to the upper steel pipe 2 to open The threaded groove 54, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com