Driving casing structure allowing silicon gel to be poured in

A technology for driving shells and shells, which is applied to lighting and heating equipment, parts of lighting devices, lighting devices, etc., which can solve the problems of high manufacturing cost, single appearance and structure, and inconvenient assembly, so as to reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

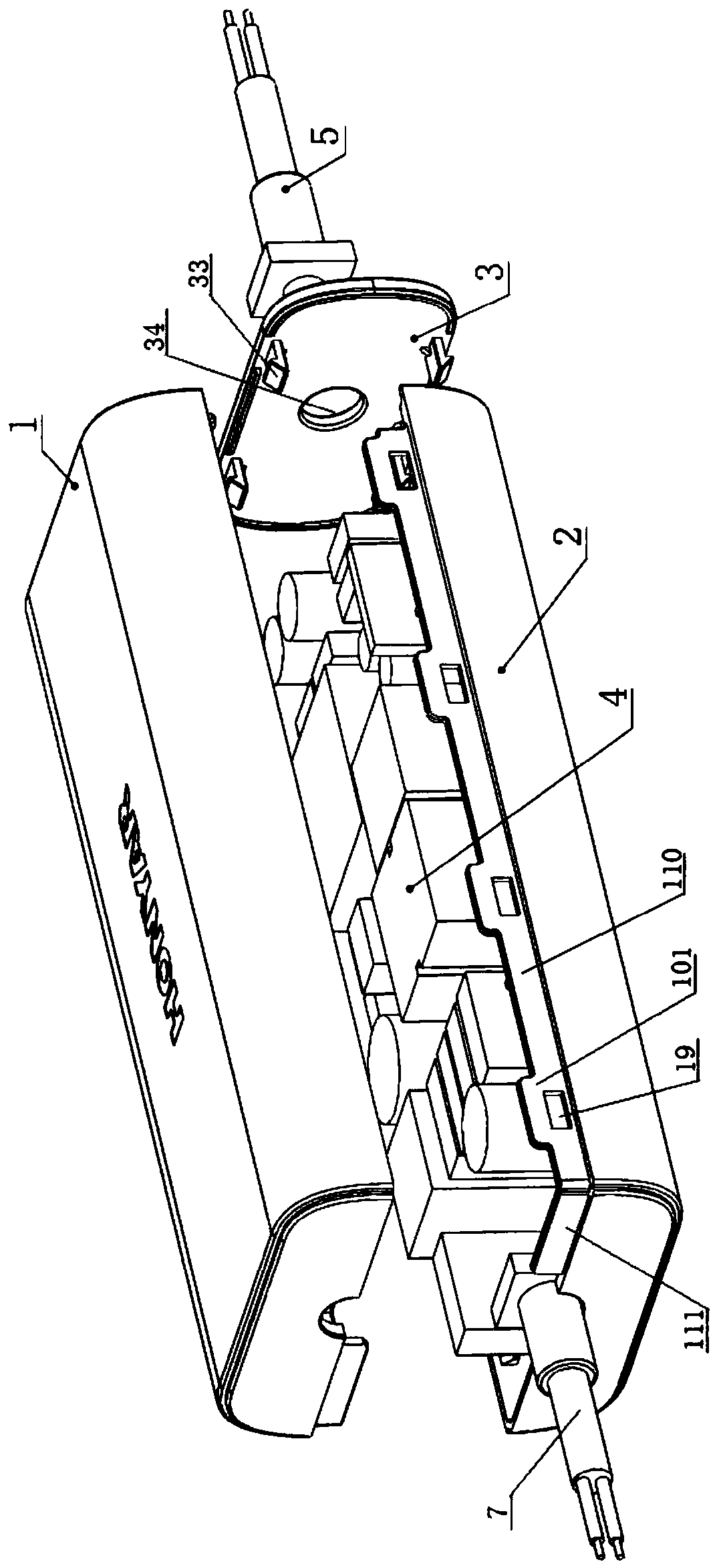

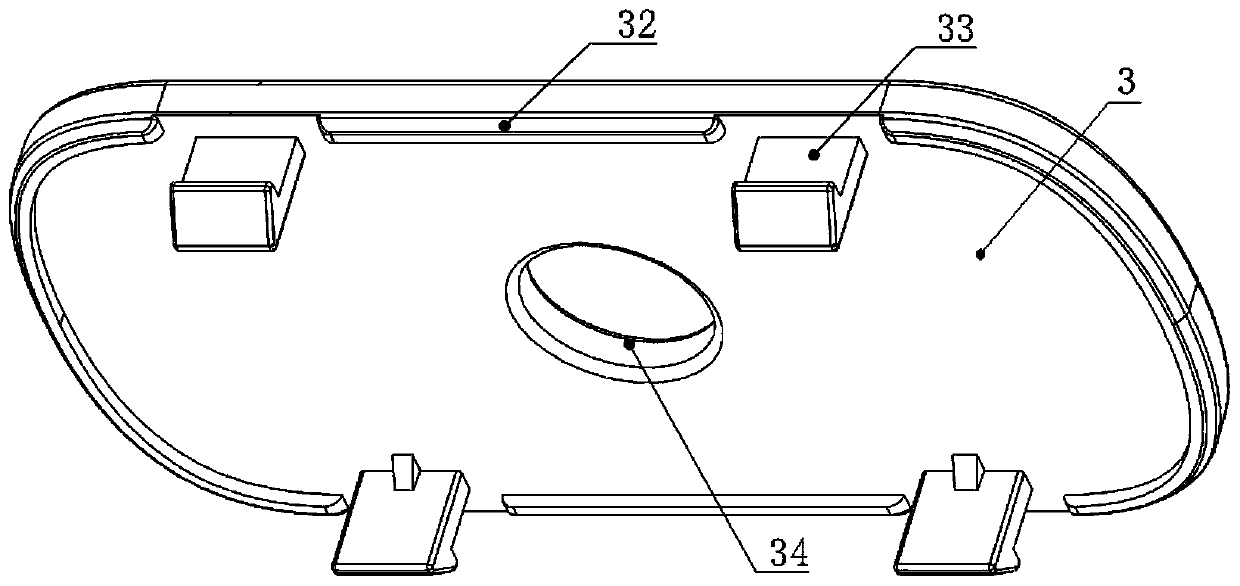

[0024] like Figure 1-5 As shown, a glue-fillable driving shell structure includes two shells 1 and a side cover 3, the two shells 1 are spliced together to form a cavity 6 for accommodating a power drive board 4, and one side of the shell 1 is provided with There is a sealing port 2, and the sealing port 2 is provided with a glue filling hole 21 for pouring silica gel, the side cover 3 is spliced at the sealing port 2, the two shells 1 are connected by a buckle structure, and the power drive board 4 is Prior art, so do not repeat them.

[0025] In further detail, the buckle structure includes a male buckle on one side of the housing 1 and a female buckle on the opposite side of the male buckle, and the male buckle is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com