Overhead underfloor heating system

A floor heating and pipeline technology, applied in the field of floor heating control, can solve the problems of floor heating water leakage is not easy to find, indoor temperature fluctuations are difficult to adjust, and adjustment lags behind, so as to prevent uneven heat transfer, save materials, and install and use immediately Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

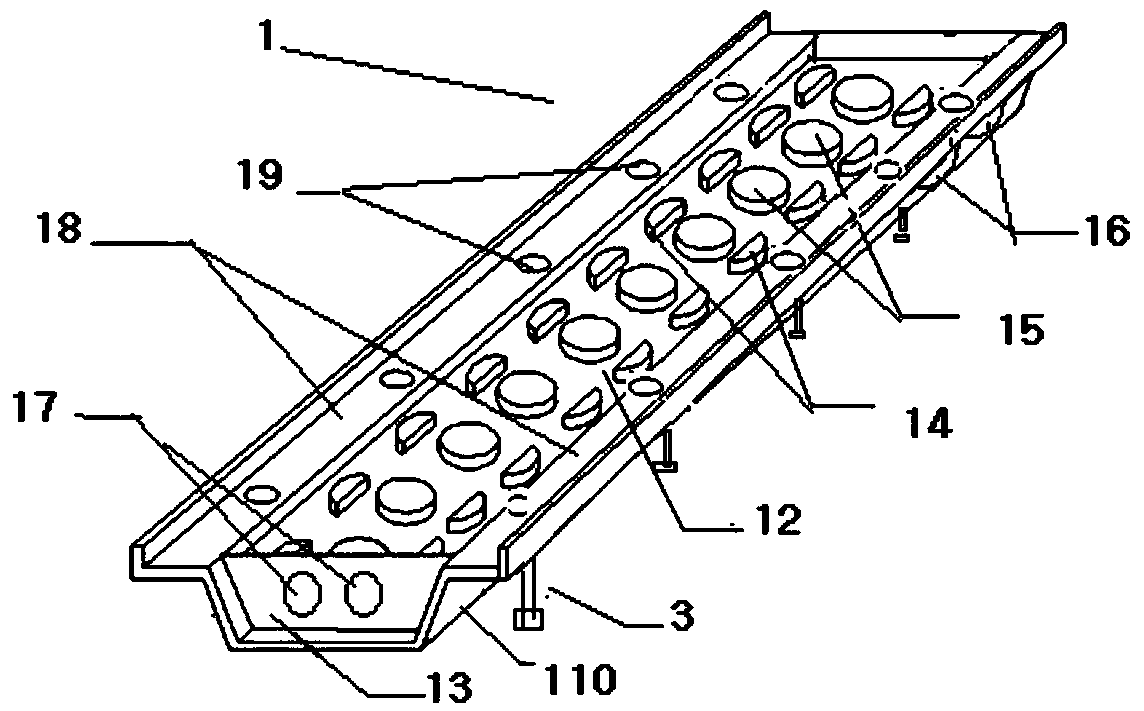

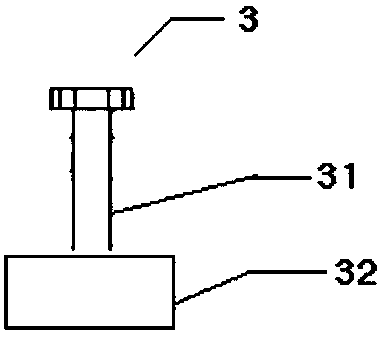

[0027] Such as Figure 1-5 As shown, the floor heating system includes: floor heating laying base layer 1, floor heating pipeline fixing layer 12, cover plate 2, partition plate 13, height adjustment rod 3, water inlet pipe through hole 17, water outlet pipe through hole 16, floor heating pipeline ( Shown among the figure) and circulating water control mechanism 4. The floor heating base layer 1 is a trapezoidal tank, the right side wall 110 of the floor heating base layer 1 is provided with a water outlet pipe through hole 16, and the left and right side walls 110 of the floor heating base layer 1 extend horizontally to form two symmetrical The table top 18, the table top 18 is evenly provided with a plurality of table top holes 19; the height adjustment rod 3 is in contact with the ground through the table top holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com