A rapid air cooling device for chemical production raw materials

A technology for chemical production and air-cooling devices, applied in heat exchange equipment, lighting and heating equipment, heat transfer modification and other directions, can solve the problems of easy accumulation, unfavorable cooling, and difficult dispersion of raw materials, and achieve high-efficiency heat exchange effect, full cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

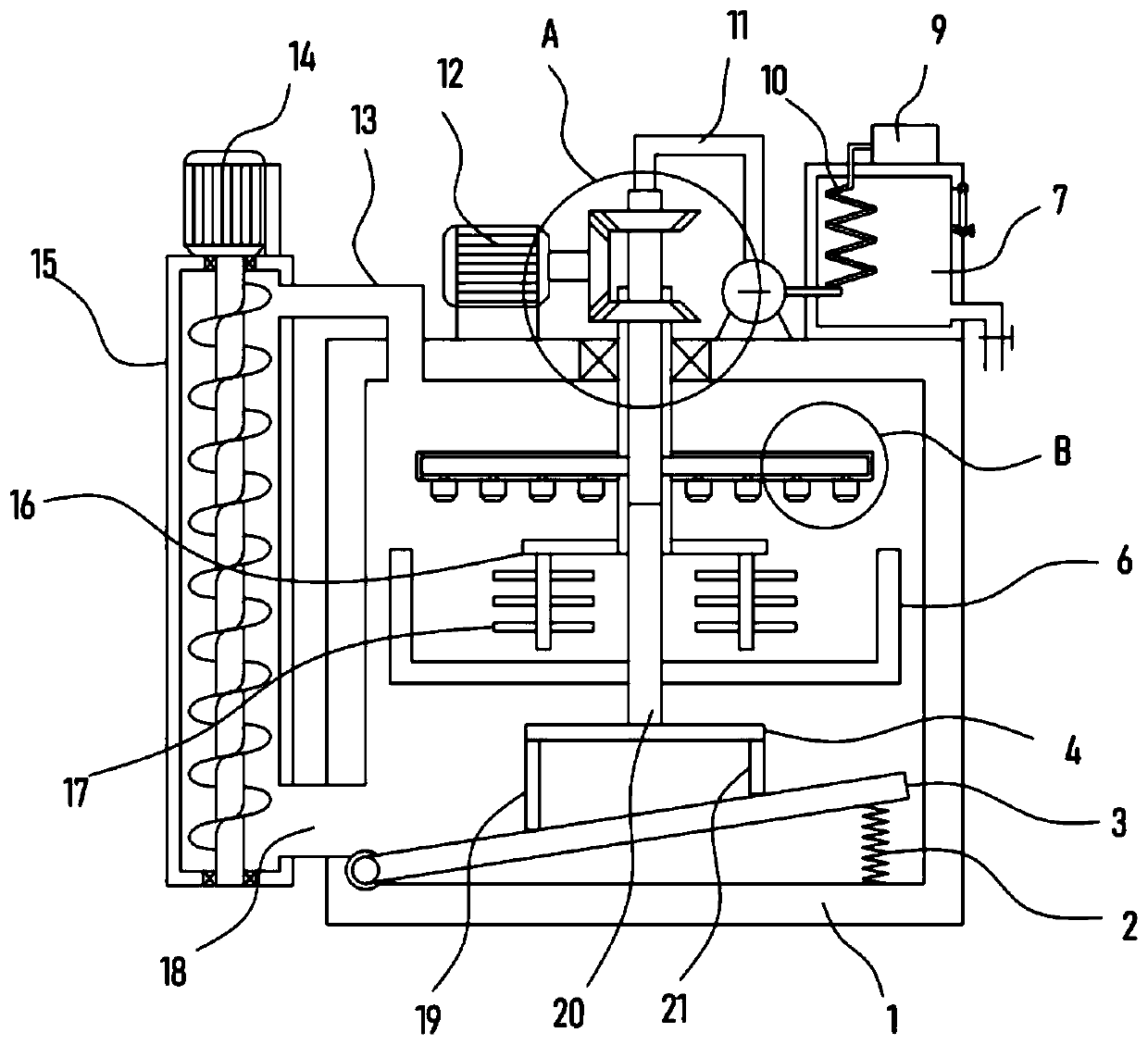

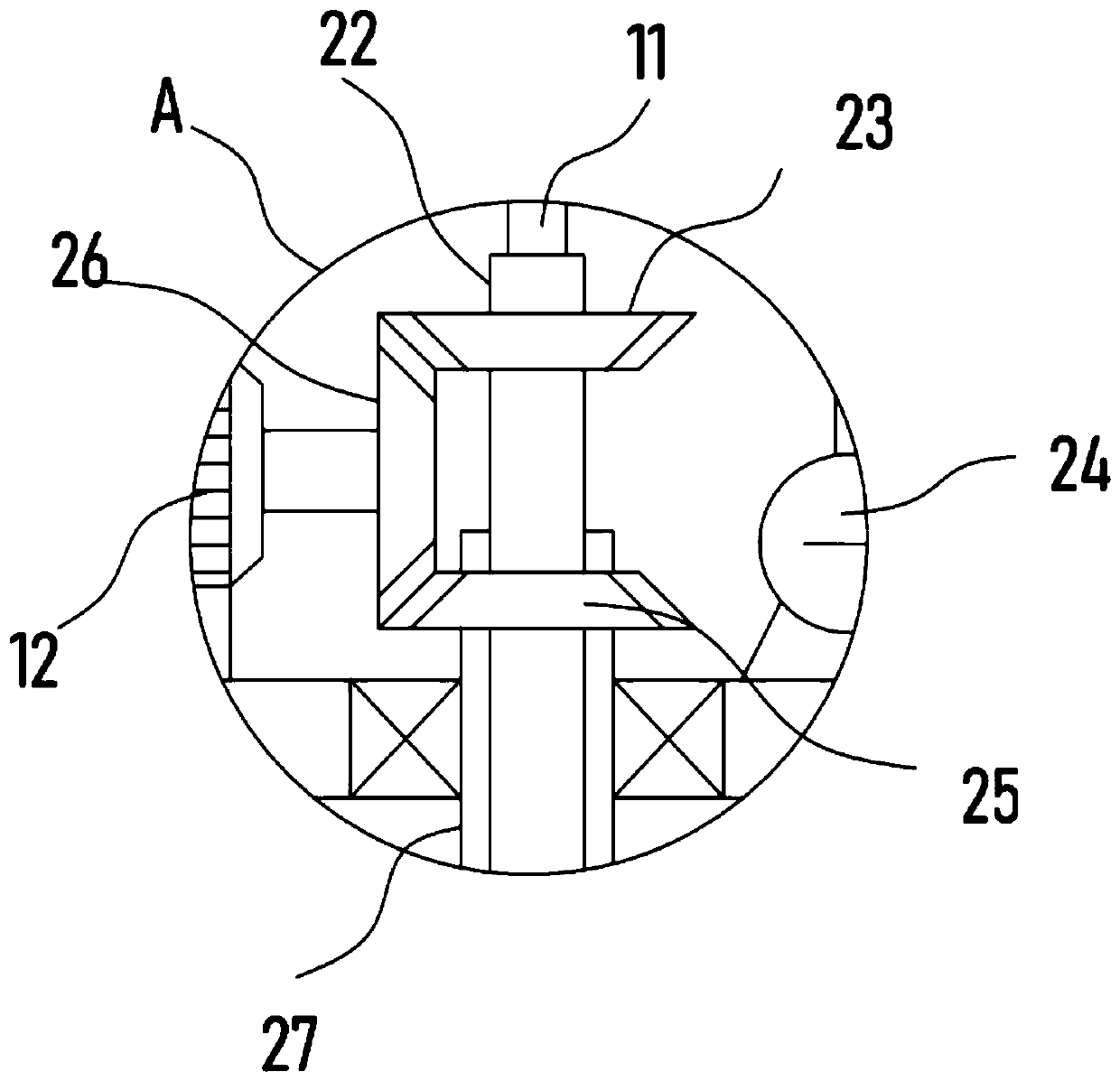

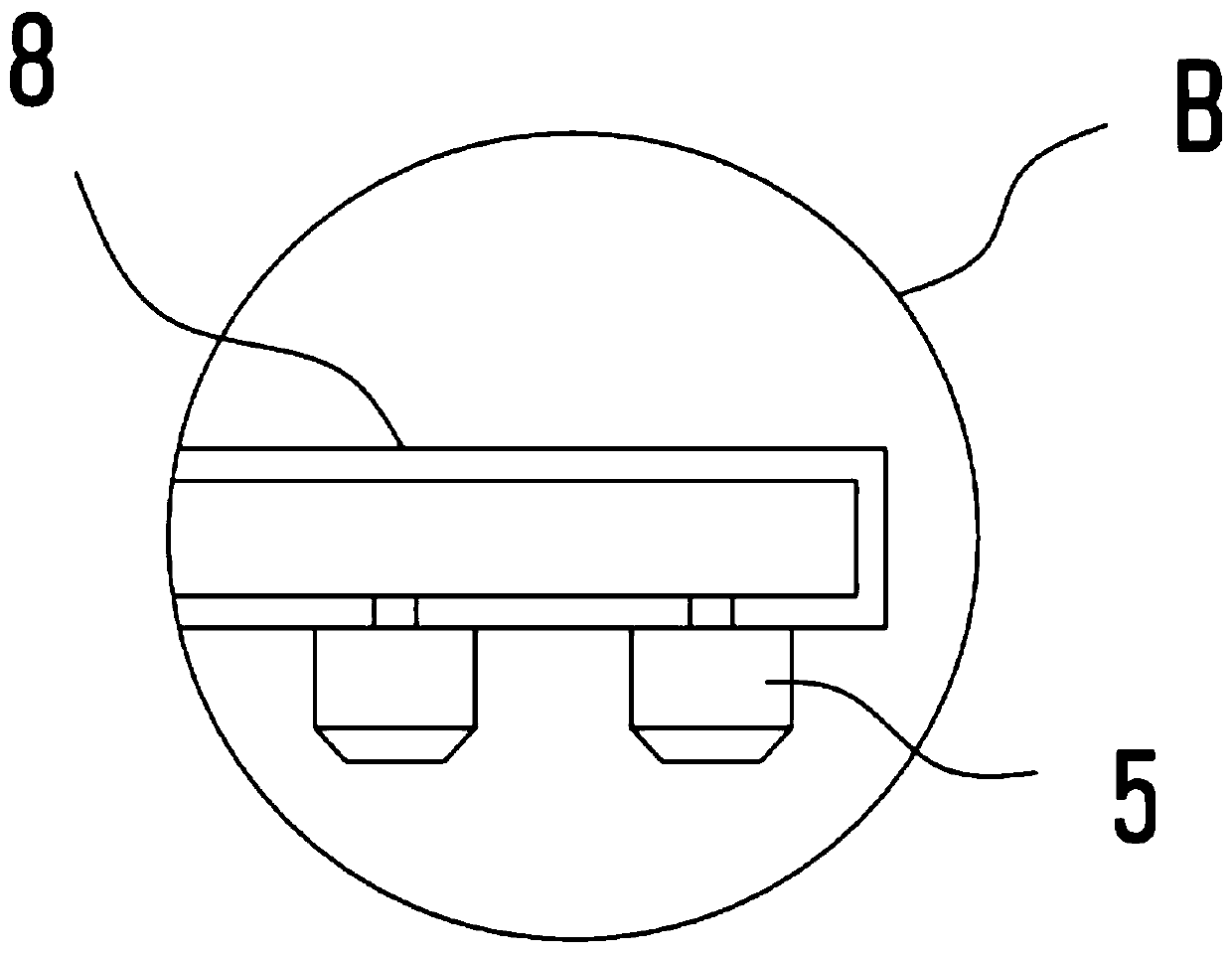

[0023] see Figure 1-5 , a kind of rapid air cooling device for chemical production raw materials, comprising a cooling chamber 1, the cooling chamber 1 is rotatably provided with an outer tube 27, the outer tube 27 is provided with a rotating inner tube 22 driven by a driving mechanism, and the outer tube 27 is horizontally fixed There is an air collecting tray 8 connected with the rotating inner pipe 22, and several nozzles 5 are evenly distributed on the bottom of the air collecting tray 8, and the air collecting tray 8 is connected with an air cooling mechanism at the top of the cooling chamber 1, and the lower side of the outer pipe 27 A dispersing mechanism is fixed on the wall, and a dispersing tank 6 is arranged under the dispersing mechanism, and a lifting auger 15 communicated with it is fixed on the side wall of the cooling chamber 1 .

[0024] The chemical raw materials are placed inside the dispersing tank 6, and the dispersing mechanism is set to rotate and dispe...

Embodiment 2

[0030] In order to further ensure the full contact between the cold air and the chemical raw materials, on the basis of Embodiment 1, the side wall of the rotating inner tube 22 is uniformly provided with several air guide holes 29 communicating with the inside of the gas collecting tray 8, and the dispersing mechanism includes rotating Frame 16, the bottom of turret 16 is provided with several dispersing blades 17, the bottom end of rotating inner tube 22 is provided with rotating shaft 20 coaxially fixed with dispersing tank 6, and the bottom of rotating shaft 20 is provided with excitation mechanism.

[0031] Through the above setting, after the air pump 24 pumps the cold air into the rotating inner pipe 22 through the intake pipe 11, the cold air passes through the air guide hole 29 and enters the inside of the gas collecting tray 8, and finally sprays downward along the nozzle 5 to the chemical industry. At the same time, the turret 16 rotates with the outer tube 27 and dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com