Steam turbine plant

A steam turbine and steam technology, which is applied to steam engine devices, mechanical equipment, engine components, etc., can solve the problem of heat energy waste of steam seal, achieve effective utilization and improve device efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

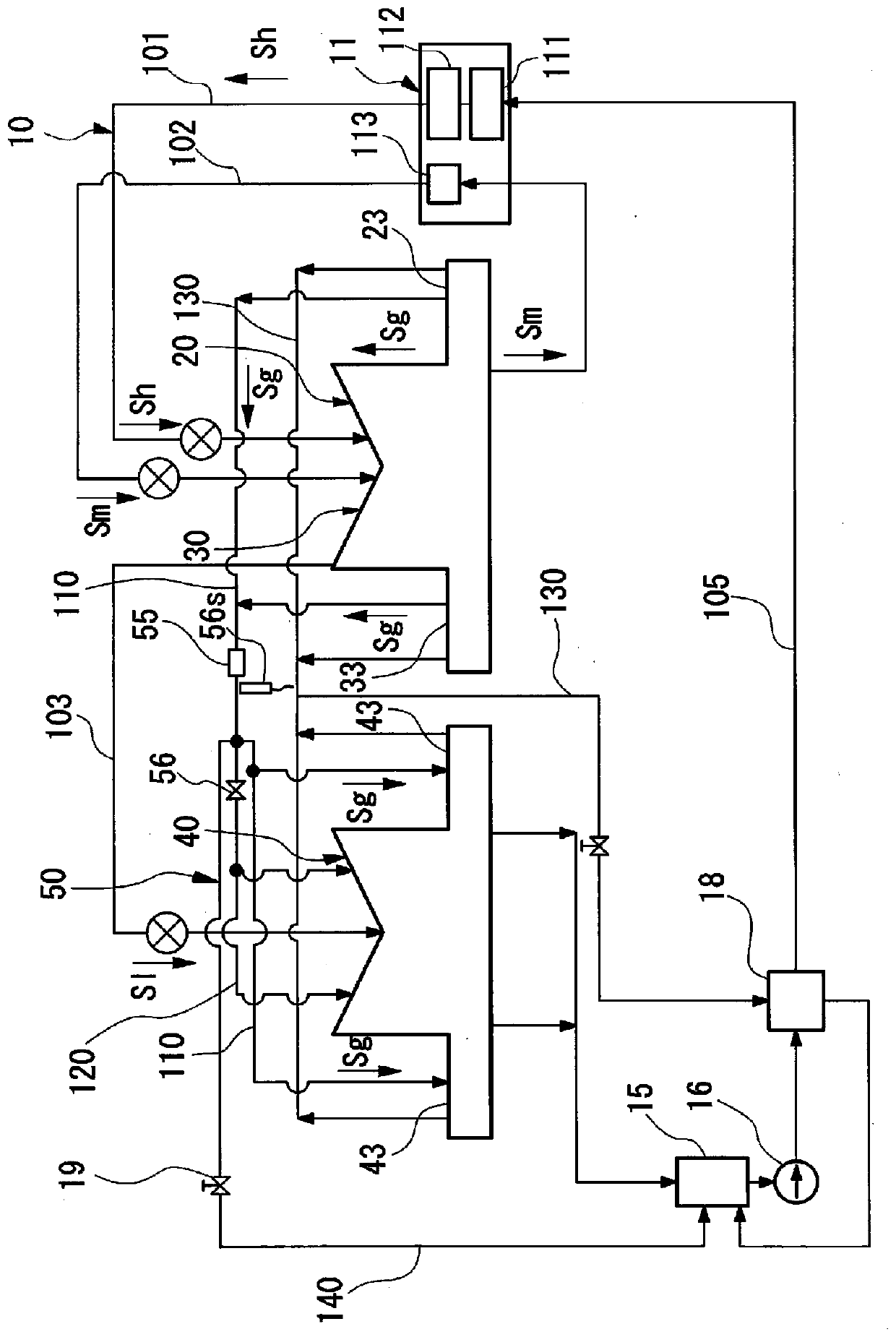

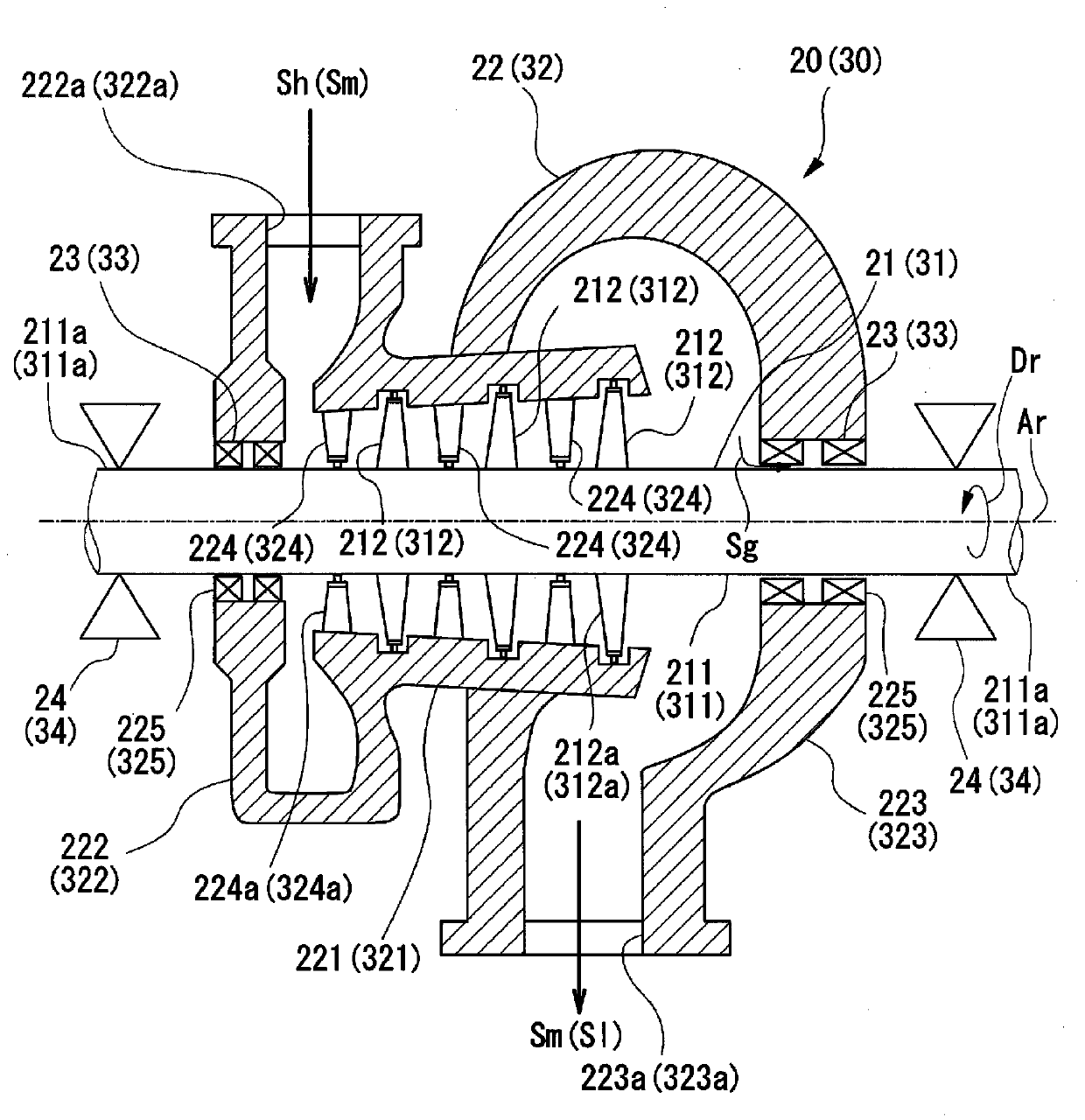

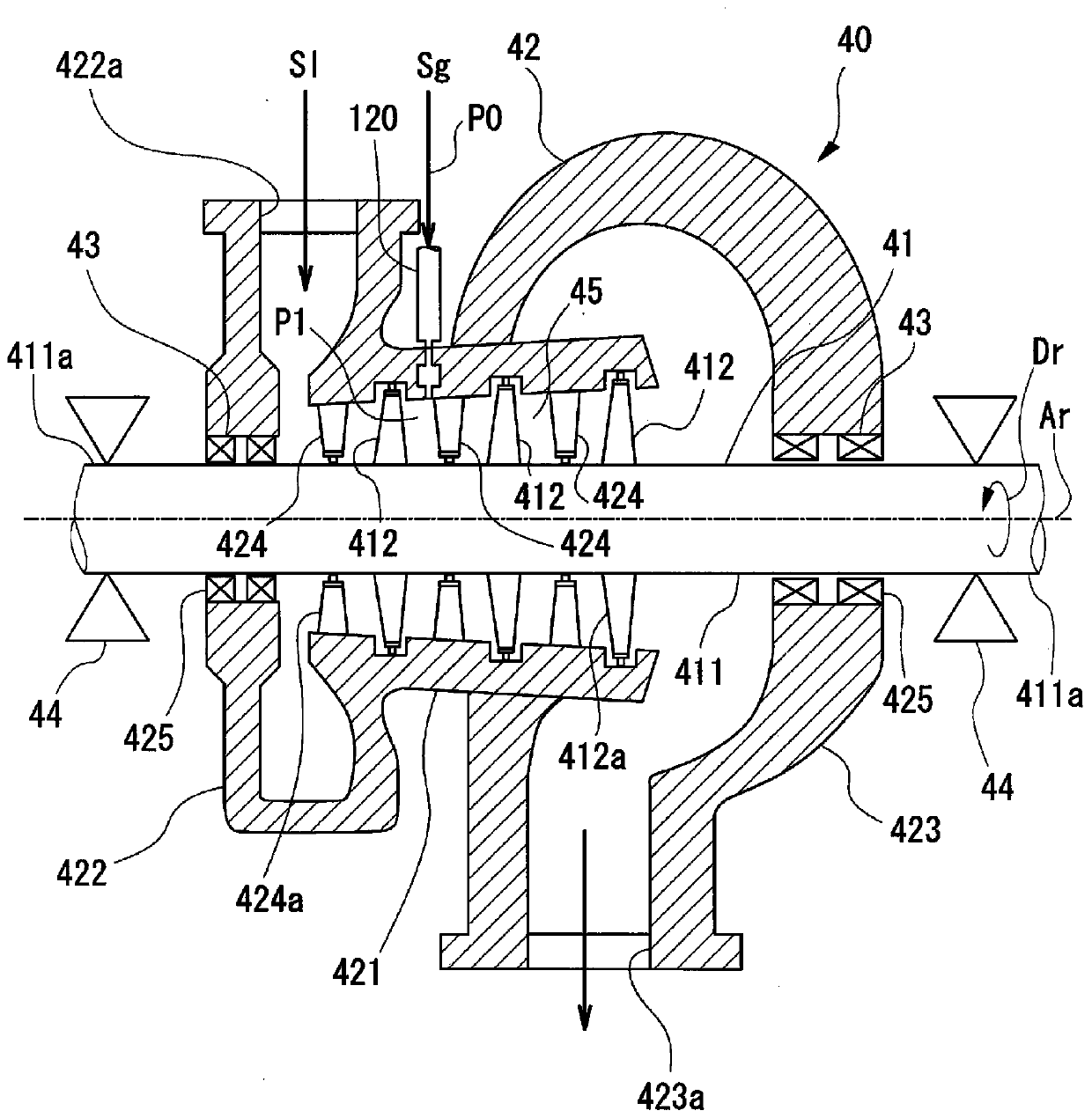

[0036] figure 1 It is a schematic diagram showing the structure of the steam turbine plant according to the first embodiment of the present invention. figure 2 It is a cross-sectional view of a high-pressure steam turbine constituting the steam turbine plant according to the first embodiment of the present invention. image 3It is a cross-sectional view of a low-pressure steam turbine constituting the steam turbine plant according to the first embodiment of the present invention. Figure 4 It is a graph showing the supply form of the seal steam at the start-up of the steam turbine plant according to the first embodiment of the present invention.

[0037] Such as figure 1 As shown, the steam turbine device 10 of this embodiment mainly includes: a boiler 11, a high-pressure steam turbine (high-pressure side steam turbine) 20, an intermediate-pressure steam turbine (high-pressure side steam turbine) 30, and a low-pressure steam turbine (low-pressure side steam turbine) 40 , c...

no. 2 approach

[0084] Next, a second embodiment of the steam turbine plant of the present invention will be described. In addition, in the following description of the second embodiment, the same reference numerals are assigned to the same configurations as those of the above-mentioned first embodiment, and description thereof will be omitted. The second embodiment differs from the first embodiment in that the seal steam Sg sent to the low-pressure steam turbine 40B through the rotor driving steam supply line 120 is supplied to a position facing the radially outer side of the moving blade row 412 . different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com