Full-open type film rolling greenhouse

A fully-open, roll-film technology, applied in greenhouse cultivation, climate change adaptation, gardening, etc., can solve the problems of poor ventilation, unsatisfactory lighting, large-area opening of the top film, etc., to achieve the effect of flexible use and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

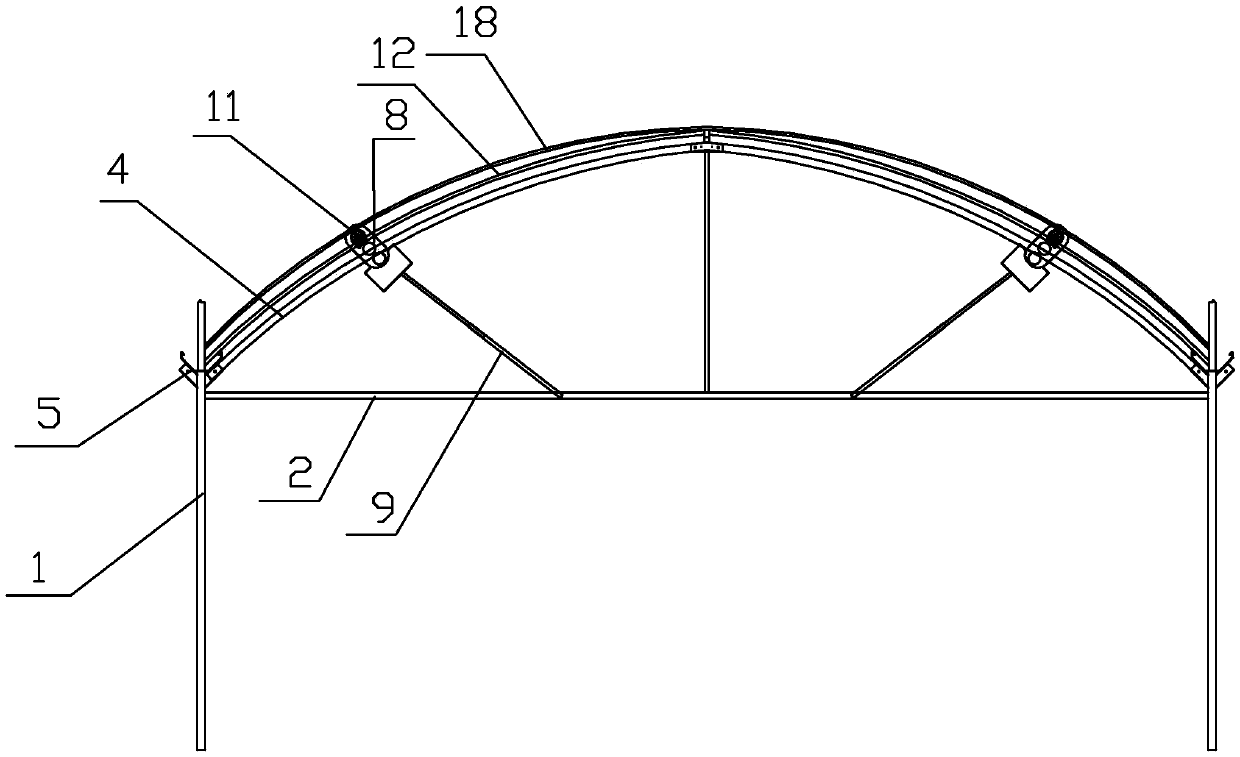

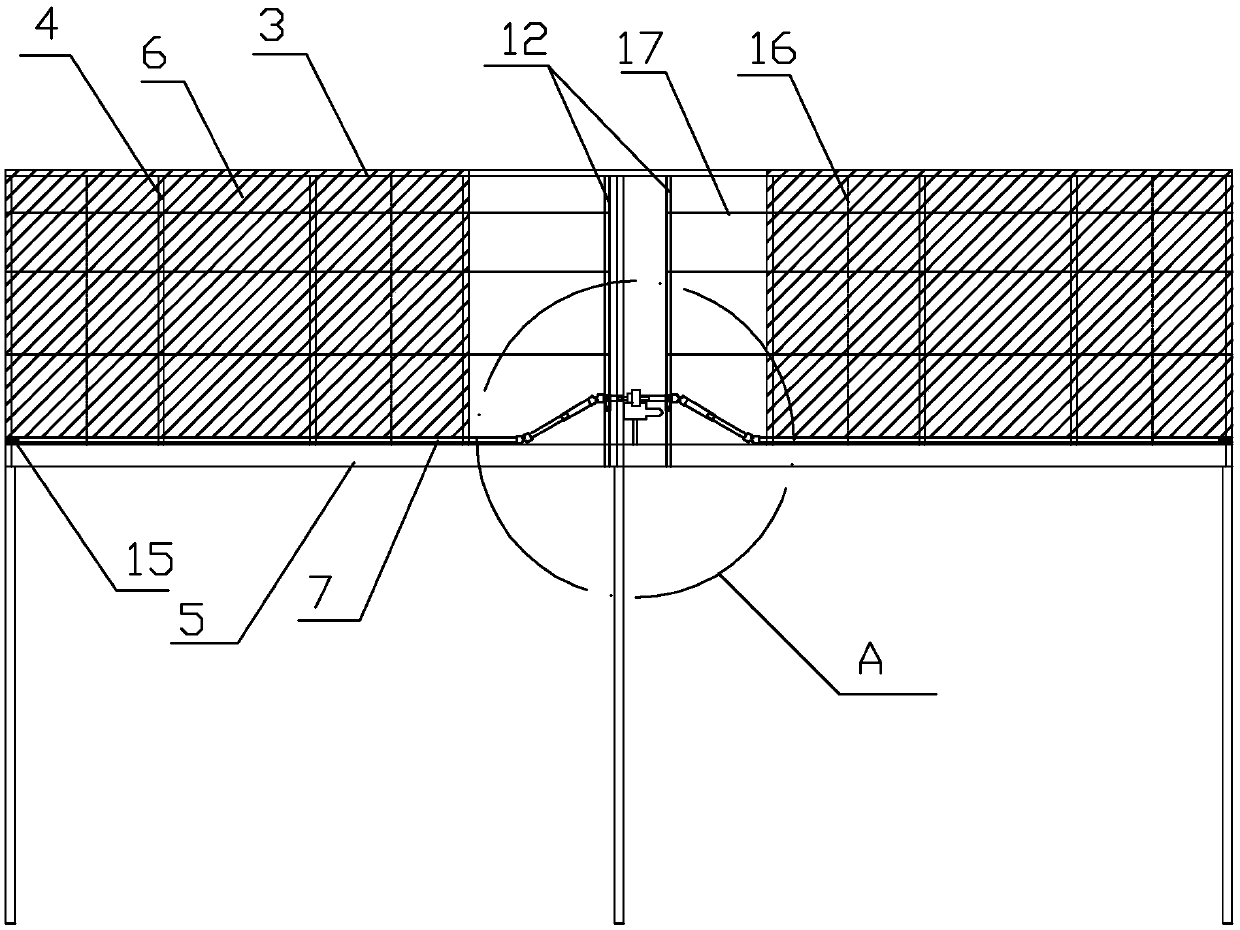

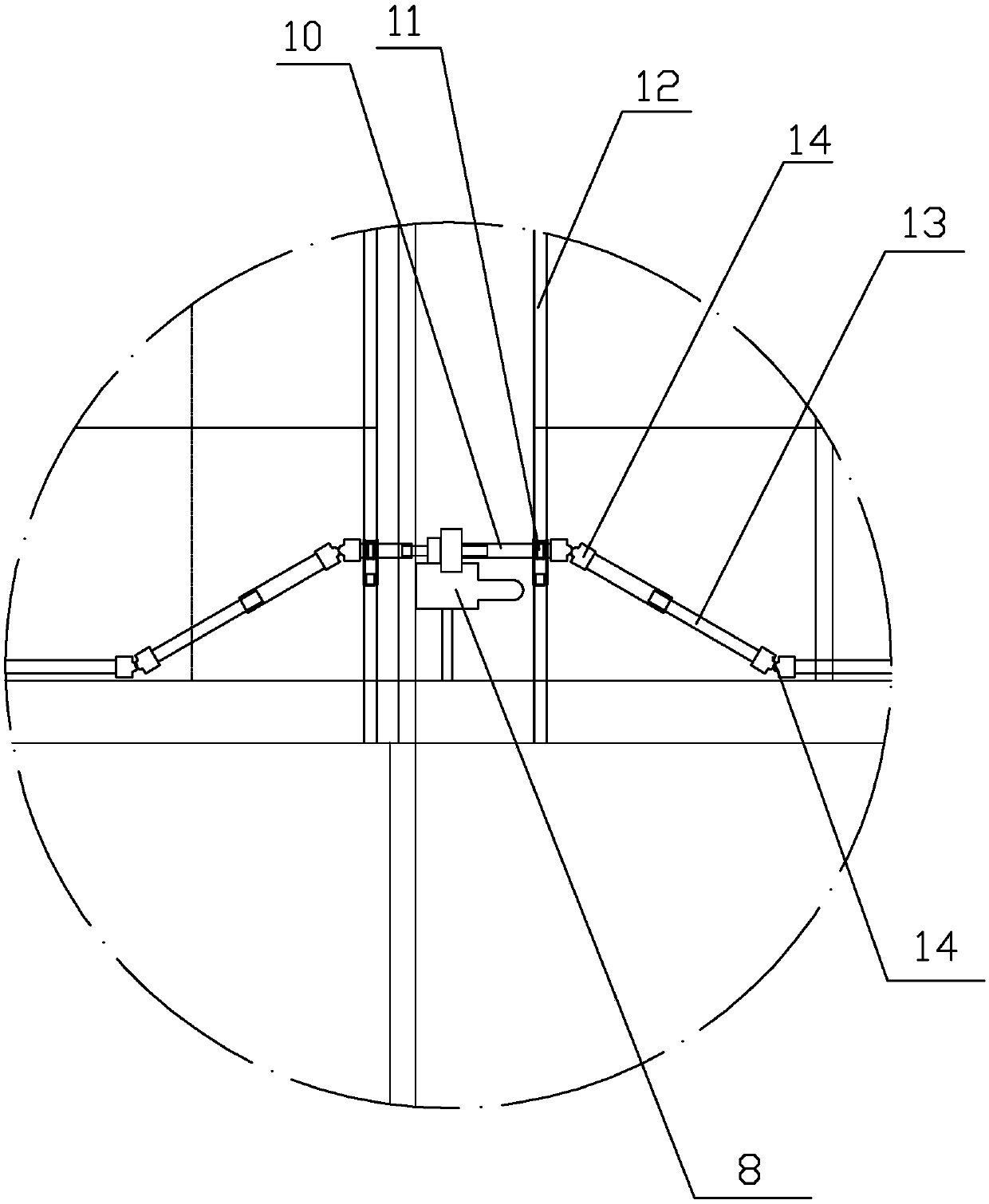

[0019] Embodiment: the fully open roll film greenhouse of this embodiment, such as figure 1 , figure 2 As shown, it includes the greenhouse support and the agricultural film covered on the greenhouse support. The greenhouse support includes connected columns 1, beams 2, top beams 3, arches 4 and gutters 5, and the top beams and gutters connect the arches together. The agricultural film on the top of the greenhouse is divided into two roll films 6, and the two roll films are arranged along the length direction of the greenhouse. , the right edge is respectively connected with a film roll rod 7, the film roll rod is placed flat on the arch bar and perpendicular to the arch bar, and the left side and the right side of the greenhouse support between the two film rolls respectively have a two-way symmetrical installation. Shaft motor 8, the bidirectional shaft motor is installed on one end of the first telescopic rod 9, the other end of the first telescopic rod is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com