Railway steel rail gluing insulation joint glue removing machine

A technology for insulating joints and gluing, which is used in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve the problems of labor-intensive peeling, time-consuming and labor-intensive, etc., to solve the problem of time-consuming and labor-intensive, quality assurance, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

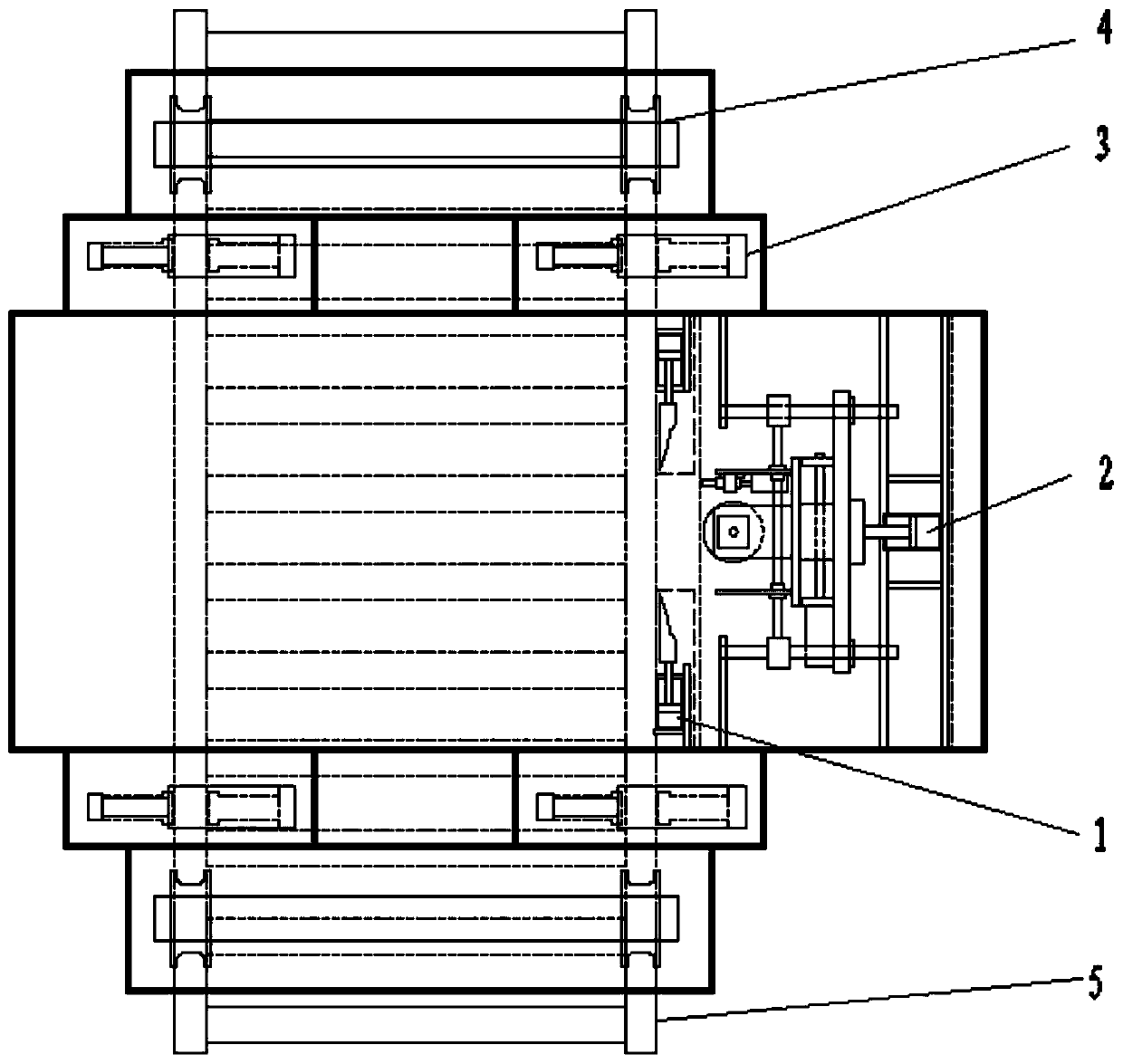

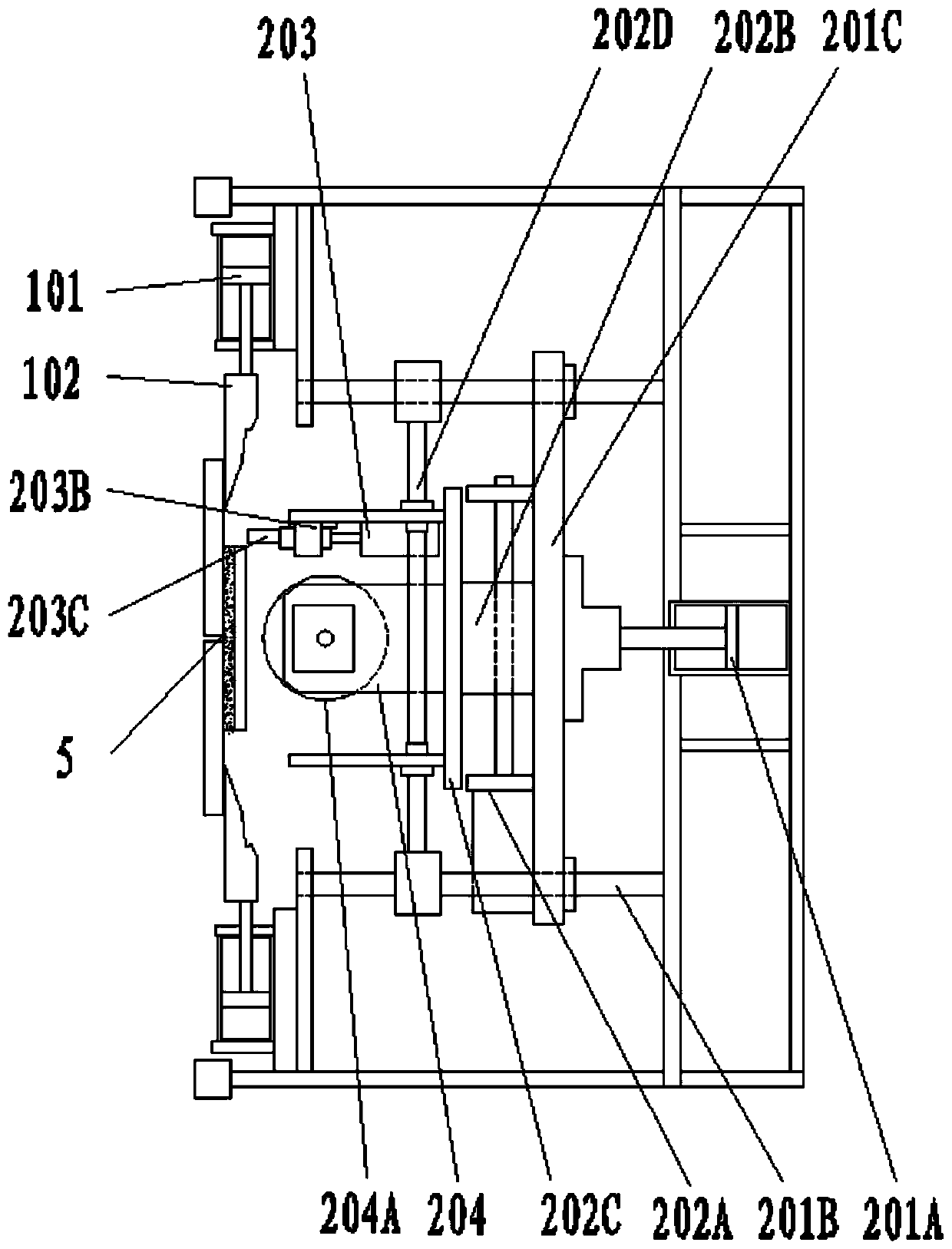

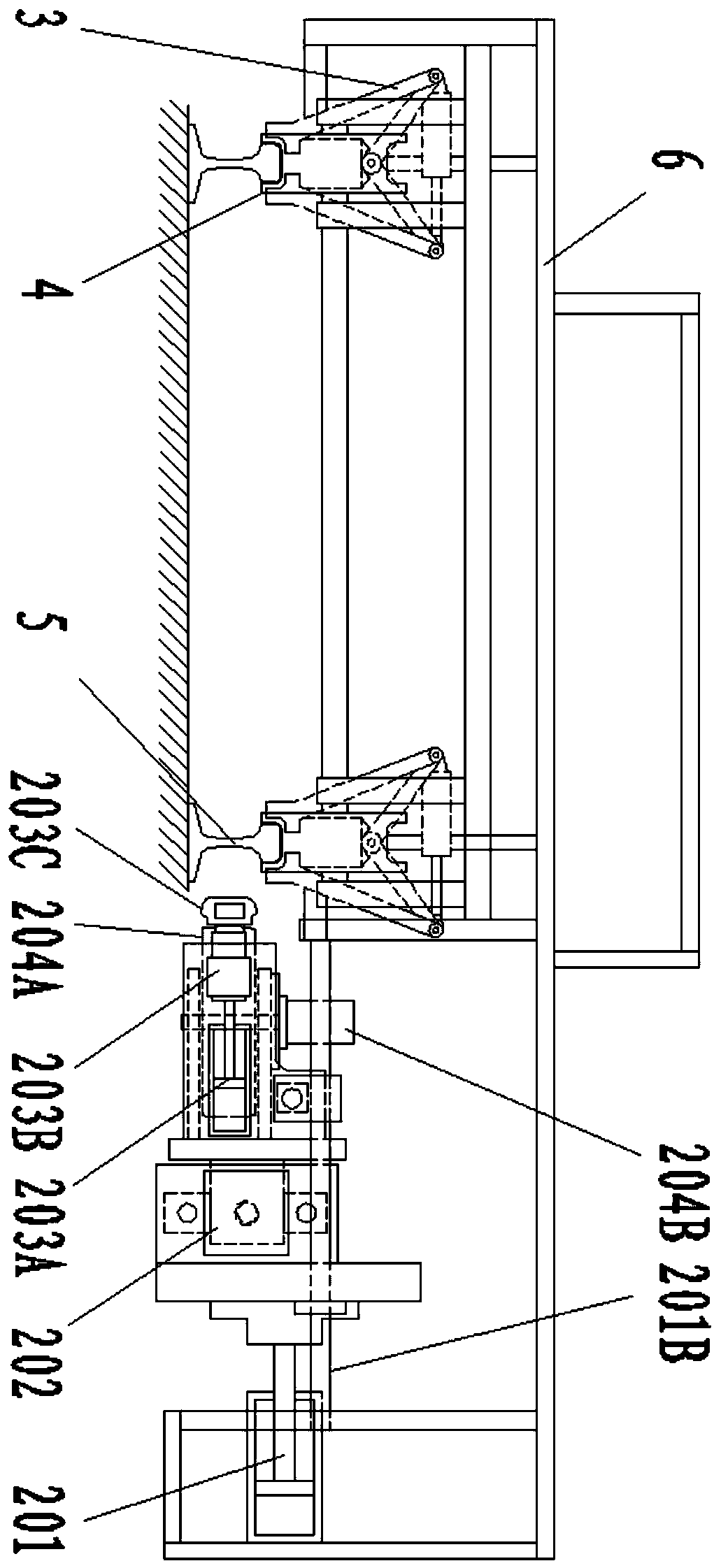

[0012] As shown in the figure, the glue remover for glued insulating joints of railway rails includes a glue breaking device (1), an adhesive removing device (2), a clamping and fixing device (3), a traveling device (4), and a frame (6); The adhesive breaking device (1), the adhesive removing device (2), the clamping and fixing device (3), and the running device (4) are all installed on the frame (6); the adhesive breaking device (1) is located in and along the direction of the track The two ends of the glued splints arranged are composed of a pair of hydraulic cylinders I (101) and dismounting heads (102) arranged symmetrically. In the horizontal position, the end of the piston rod is fixedly connected to the removal head (102), and the moving direction of the piston rod of the hydraulic cylinder I (101) is along the axis of the track (5); the adhesive removal device (2) is located at the vertical Directly ahead, it includes a vertical alignment mechanism (201), a horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com