A vertical multi-component high-viscosity material continuous feeding mixer and its application method

A multi-component and mixer technology, applied to mixers with rotating stirring devices, chemical instruments and methods, mixers, etc., can solve problems such as difficulty in ensuring production or construction technology, inability to achieve continuous material supply, and affecting construction progress , to achieve the effect of improving labor productivity, good material supply continuity and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

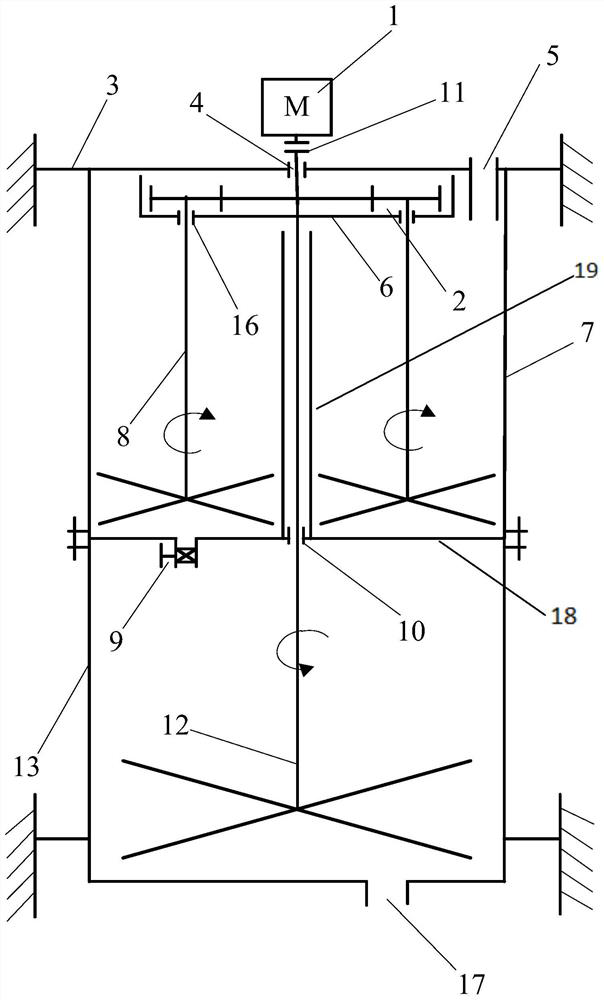

[0027] A vertical continuous feed mixer for multi-component highly viscous materials such as figure 1 As shown, it includes a mixing tank, the mixing tank is fixed on the frame 3, an agitator is arranged in the mixing tank, and a power system 1 for driving the agitator is arranged outside the mixing tank, the mixing tank is assembled, and the premixing tank 7 The bottom of the tank coincides with the tank top of the feed tank 13, the premix tank 7 is located above the feed tank 13, and the premix tank 7 and the feed tank 13 are located on the same axis, and the top of the premix tank 7 on the upper part of the mixing tank is set There is a feed port 5, and the bottom of the feed tank 13 at the lower part of the mixing tank is provided with a discharge port 17, and the premix tank 7 and the feed tank 13 are connected through an openable feed hole 9, and the feed hole 9 is opened and closed by a valve control .

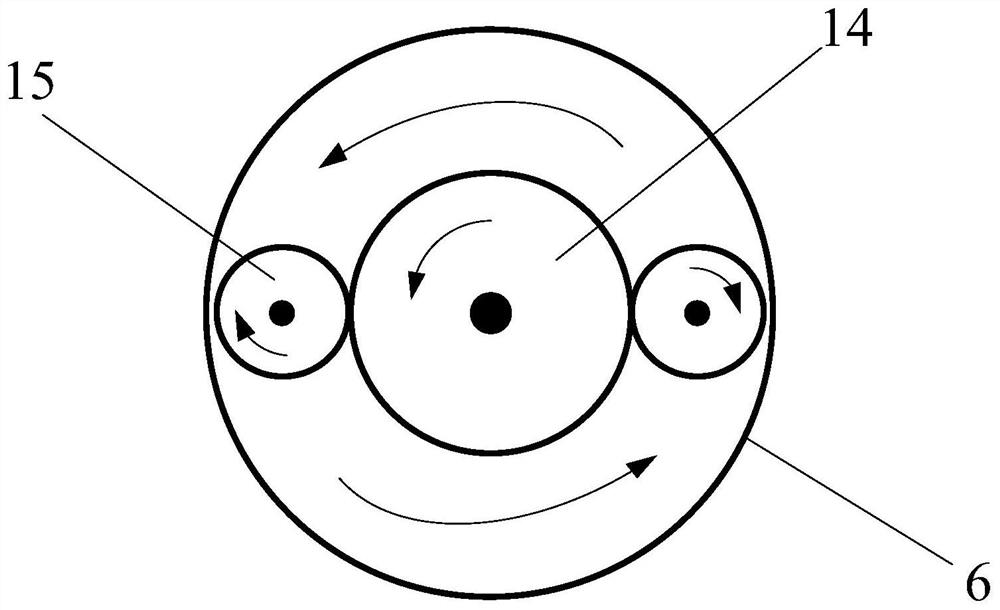

[0028] Further, as figure 1 and figure 2 As shown, the agitato...

Embodiment 2

[0043] A vertical multi-component high-viscosity material continuous feeding mixer, its structure refers to embodiment 1. Wherein, the stirring tank is integrally formed, the tank bottom of the premixing tank overlaps with the tank top of the feed tank, and a dividing plate 18 is set in the middle of the stirring tank (see figure 1 ) to form a premix tank and a feed tank, that is, the dividing plate 18 is simultaneously used as the bottom of the premix tank and the top of the feed tank; the premix tank is above the feed tank, and the premix tank and the feed tank are located On the same axis, there is a feed inlet on the top of the premixing tank on the upper part of the mixing tank, and a feeding outlet on the bottom of the feeding tank on the lower part of the mixing tank, and the premixing tank and the feeding tank are connected through an openable material hole. The opening and closing of the feed hole is controlled by a valve.

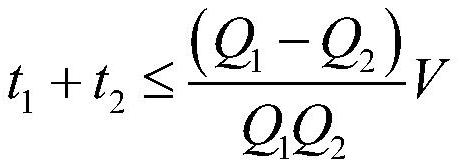

[0044] The working principle of the vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com