Vibrating screen angle regulating mechanism with limit function

An angle adjustment and function technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems that cannot be adjusted, can not meet the mud screening, and affect the mud purification effect, so as to reduce working noise, prevent mud splashing, Enhanced firmness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

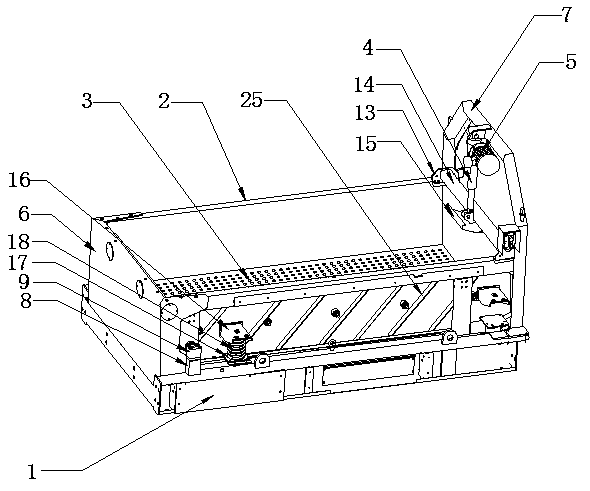

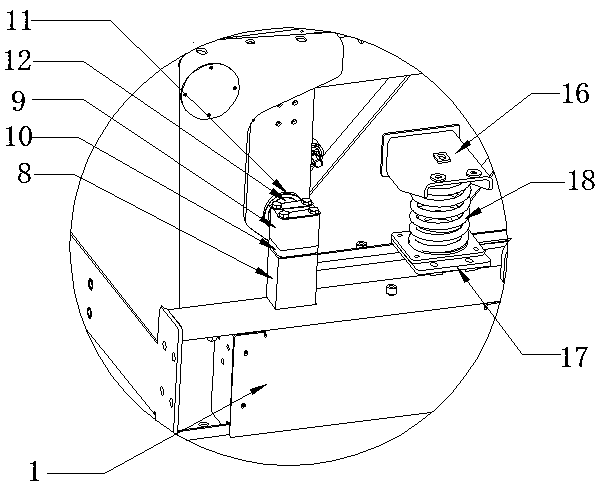

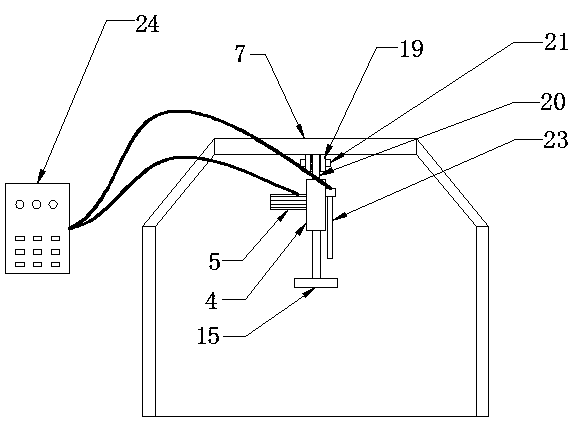

[0022] as attached Figure 1-5 As shown, an angle adjustment mechanism with a limit function for a vibrating screen includes a base 1, a screen support 2, a screen 3, an electric push rod 4, and a drive motor 5. One end of the base 1 is provided with a baffle 6 and the other One end is provided with a support frame 7, and one end of the base 1 close to the baffle plate 6 is provided with a fixed column 8, the upper part of the fixed column 8 is provided with a movable block 9, and a shock-absorbing gasket 10 is arranged between the movable block 9 and the fixed column 8 , the movable block 9 and the damping gasket 10 are fixed to the fixed column 8 through bolt connection;

[0023] One end of the screen support 2 is provided with a bearing 11, a rotating shaft 12 is installed in the bearing 11, the outer end of the rotating shaft 12 is installed on the movable block 9, and the other end of the screen support 2 is provided with a mounting plate 13 , the beam 14 is set between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com