Mining endless rope winch steel wire rope anti-floating automatic passing device and method

A technology of infinite rope winch and steel wire rope, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of complex rope pressing device, etc., and achieve the effect of avoiding floating rope, ensuring stability and reducing danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

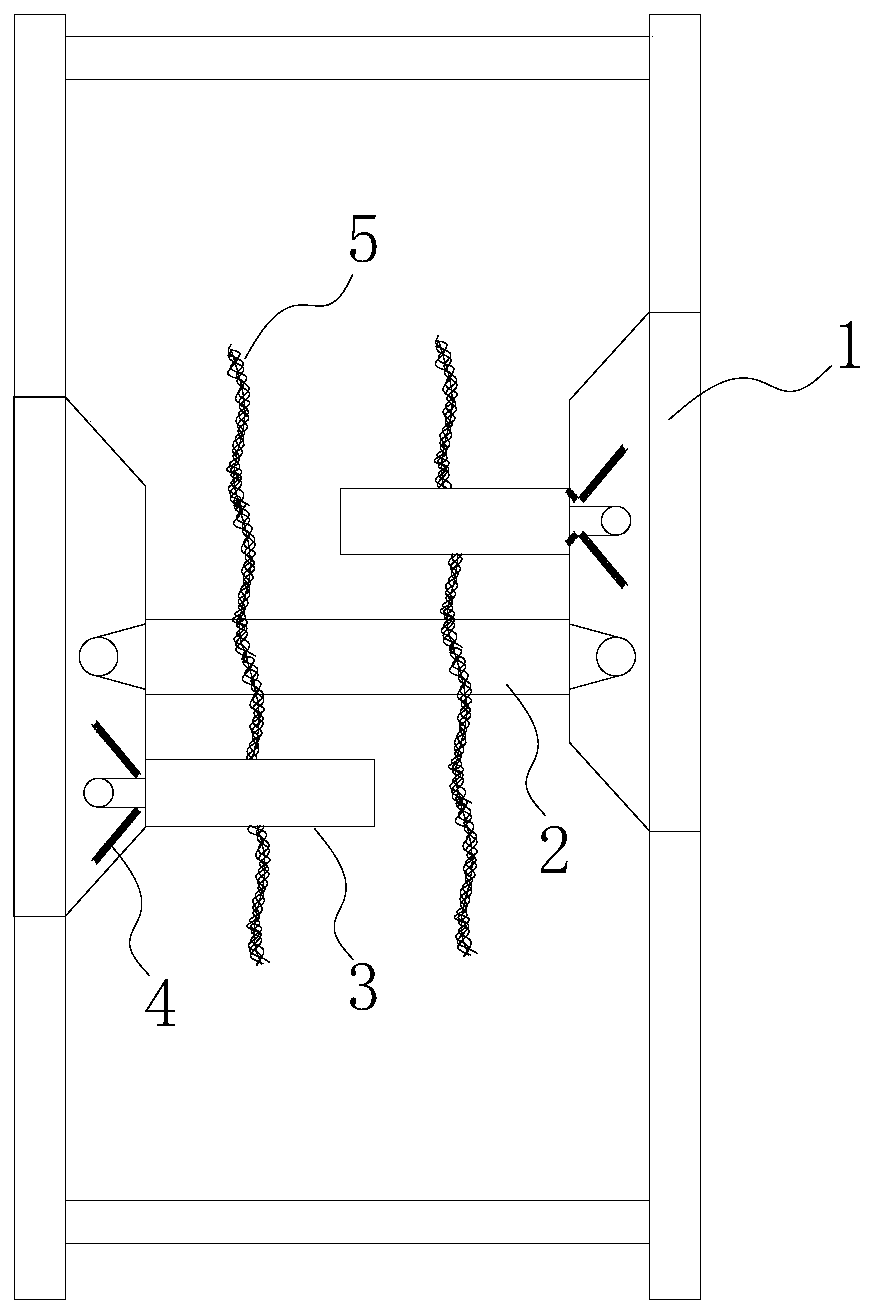

[0027] combine Figure 1 to Figure 7 As shown, a mine-used endless rope winch steel wire rope anti-drifting automatic passing device and method provided by the present invention are implemented in the following manner.

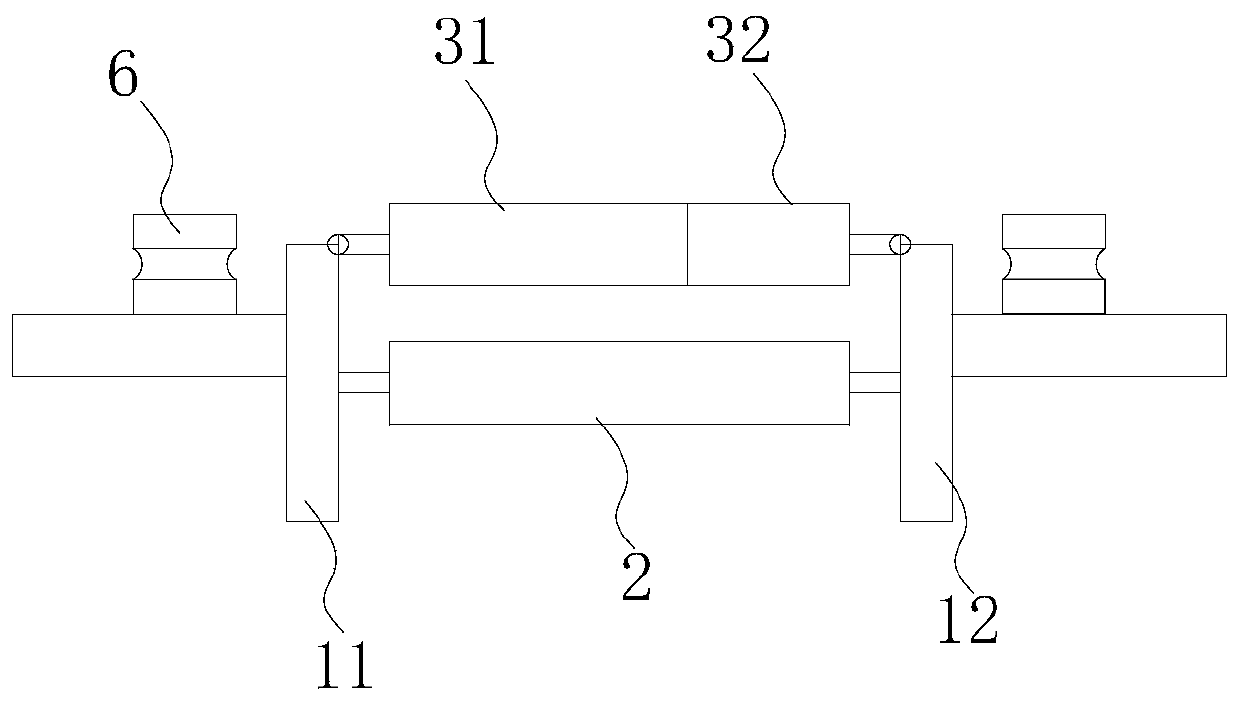

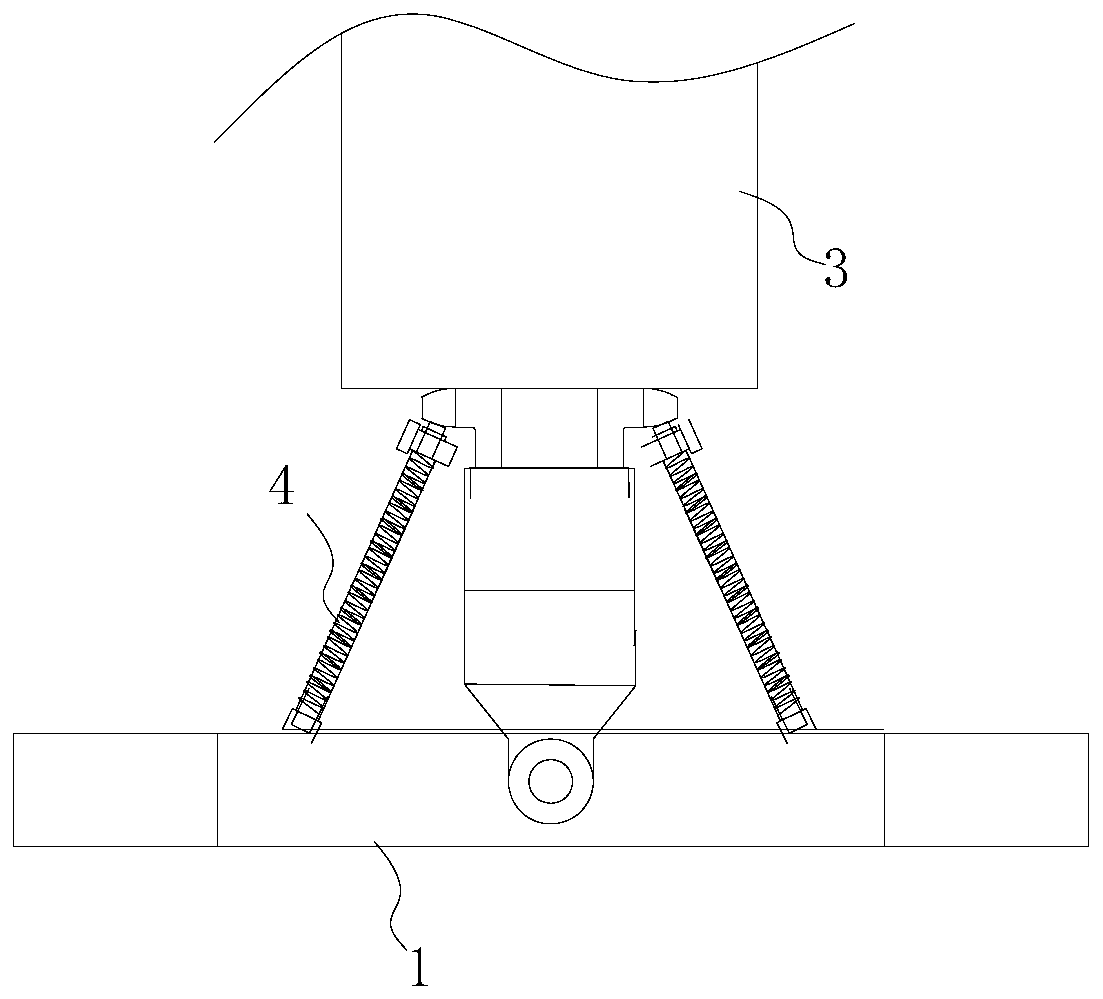

[0028] A mining endless rope winch steel wire rope anti-floating automatic vehicle passing device. The specific structure includes a fixed base 1, a long rope support roller 2, a rope pressure wheel 3 and a return spring 4. The device is fixed on the bottom of the mine car track 6 through the fixed base 1. Also by long support roller 2 and pressure rope wheel 3 pressure set steel wire rope 5, back-moving spring 4 drives pressure rope wheel 3 to reset automatically in time, guarantees that the upward floating of steel wire rope 5 in the process that mine car passes through. The fixed base 1 includes a left connecting part 11 and a right connecting part 12. The fixed base 1 is fixed on the mine car track 6 through nuts and pressing pieces, specifically on the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com