Cooling device of draw texturing machine

A technology of cooling device and texturing machine, applied in the field of silk thread processing, which can solve the problems of no heat dissipation structure of the cooling device, poor cooling stability, unstable inlet water temperature, etc., and achieve the effect of reliable cooling and guaranteed cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

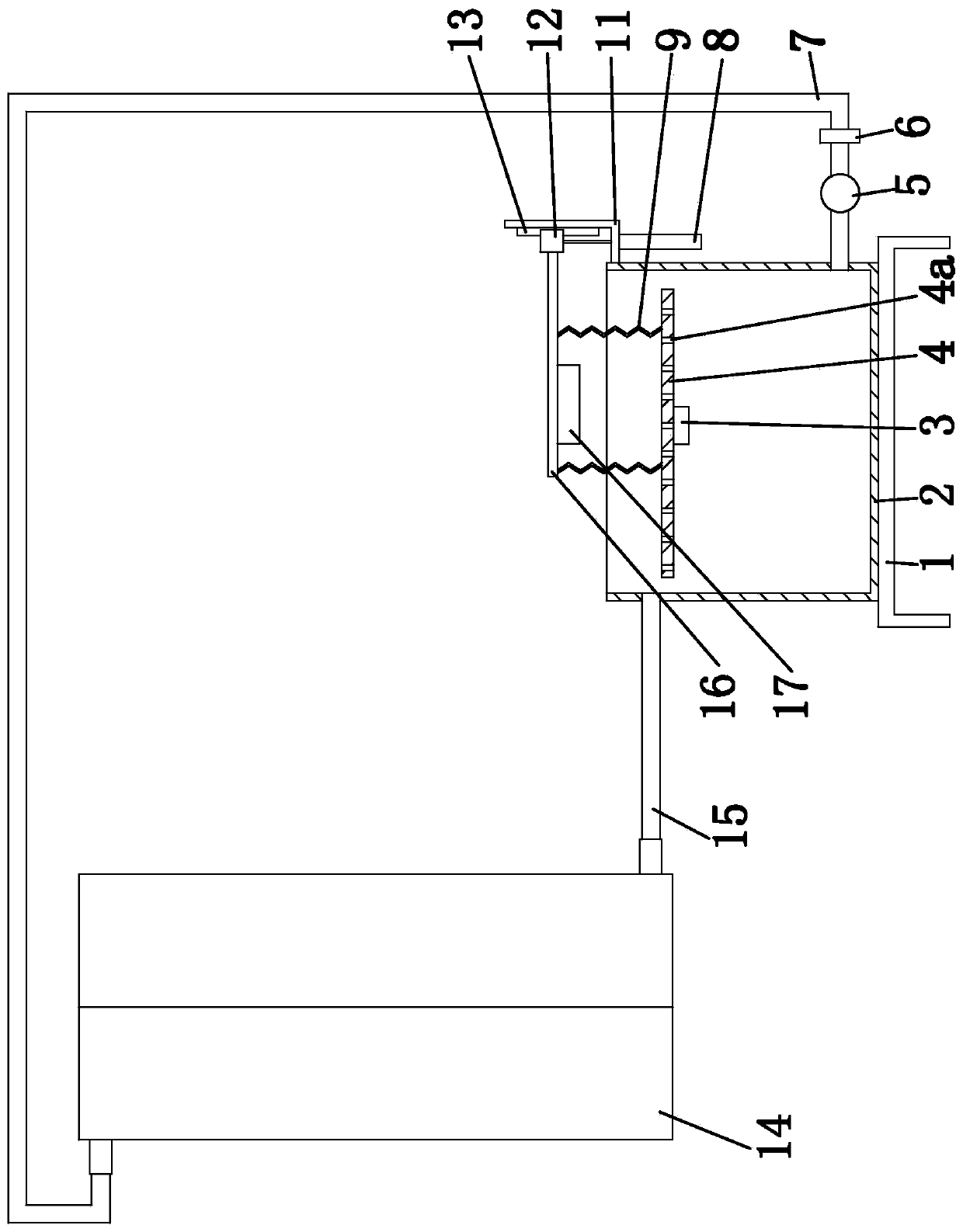

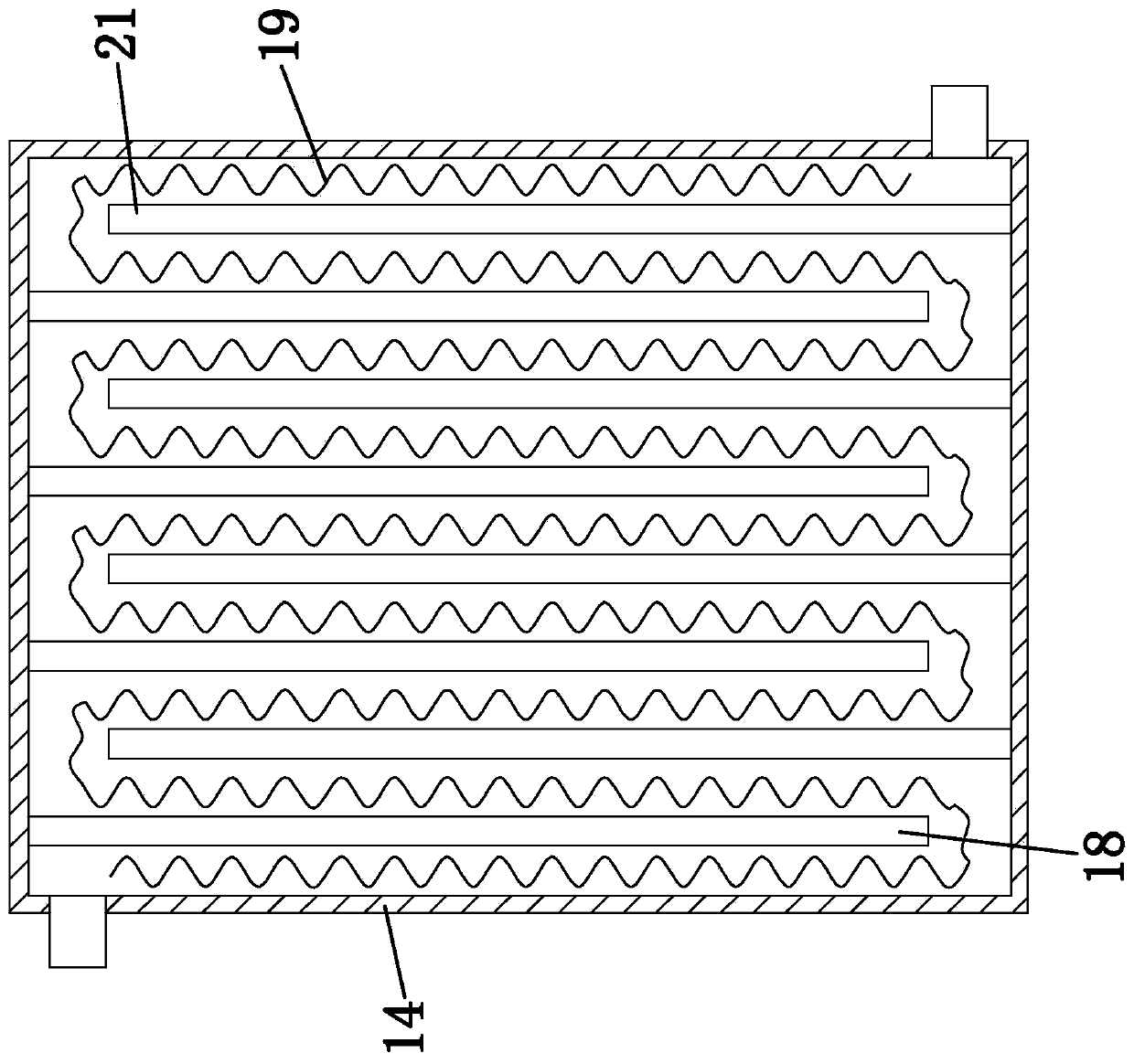

[0023] like Figure 1-Figure 2 As shown, the cooling device of the texturing machine, the texturing machine includes a frame 1, the cooling device includes a cooling plate 14 and a water storage tank 2, and the cooling plate 14 is fixed on the frame 1. In this embodiment, the cooling plate 14 passes through The way of bolt connection is fixed on the frame 1; the cooling plate 14 has a cavity inside, and the cavity is provided with some first partitions 18 and some second partitions 21. In this embodiment, the first partitions 18 The quantity is four, and the quantity of the second dividing plate 21 is four; Cooling channel is formed between the cooling plate 14, the first dividing plate 18 and the second dividing plate 21,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com