Forced closing suction valve and inclined shaft oil well pump

A technology of forced closing and suction valve, applied in the direction of pumps, pump components, variable displacement pump components, etc., can solve the problems of economic loss, affecting work efficiency, and short service life of forced valves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments. Obviously, the described embodiments are part of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

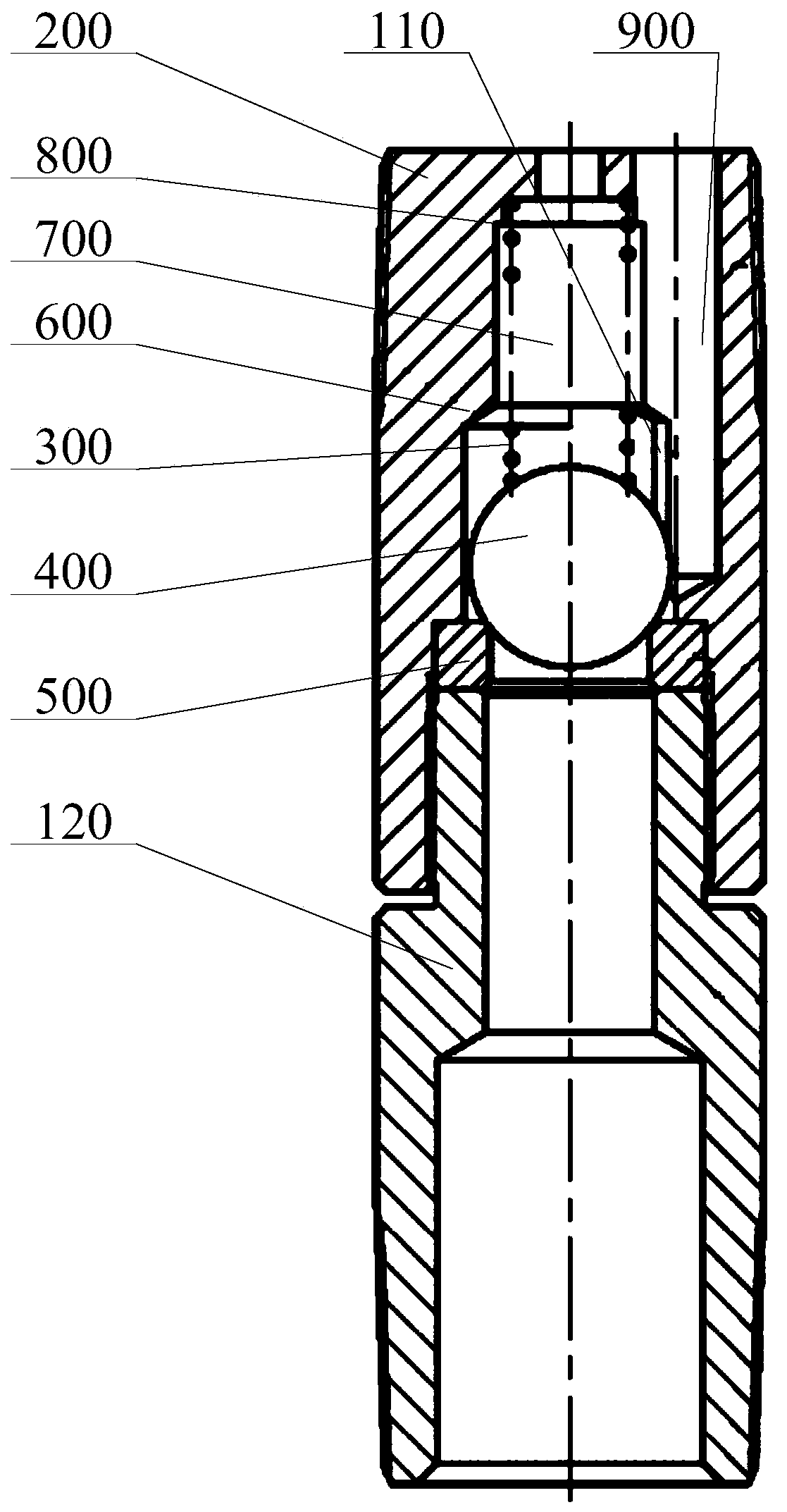

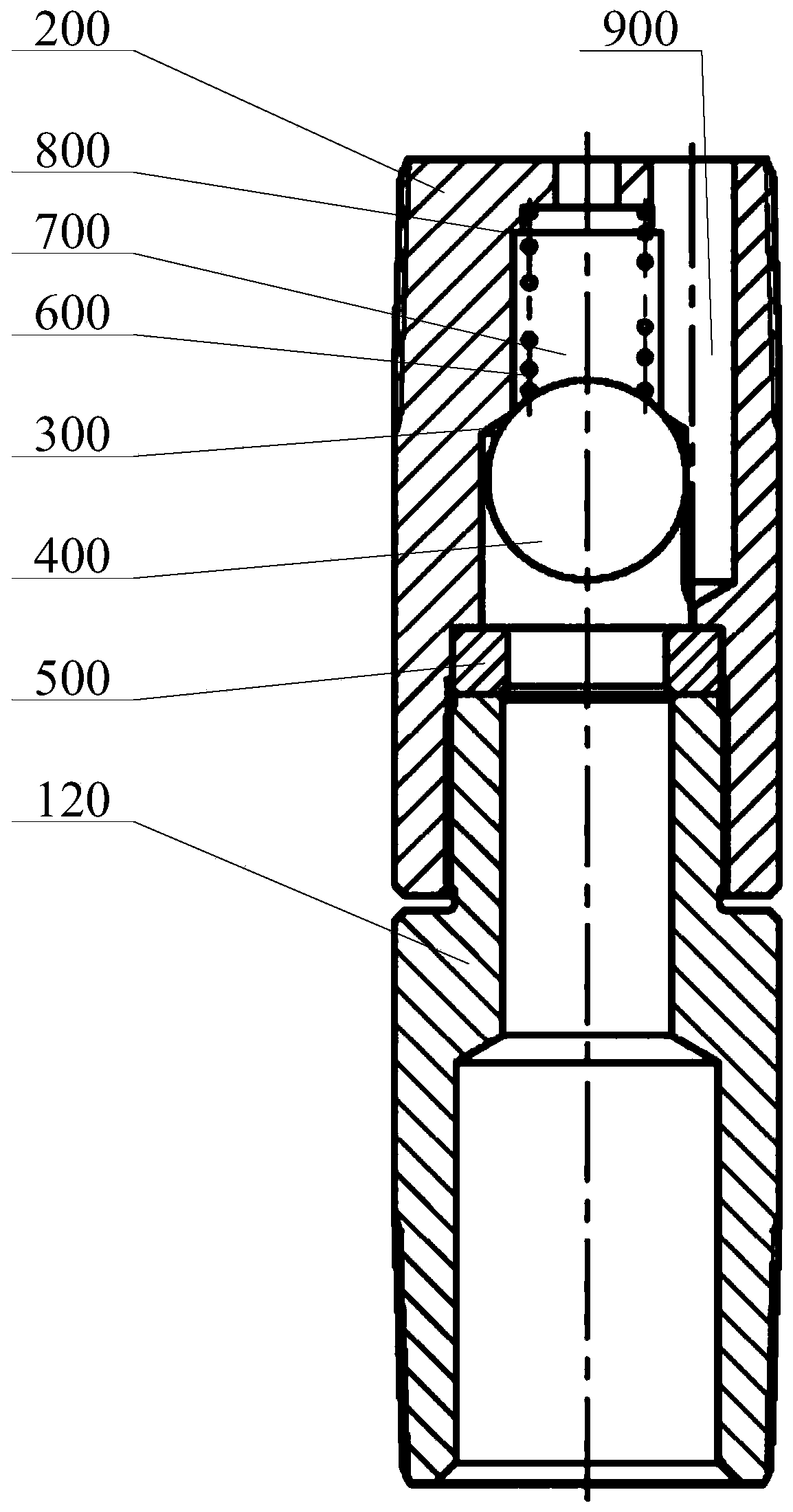

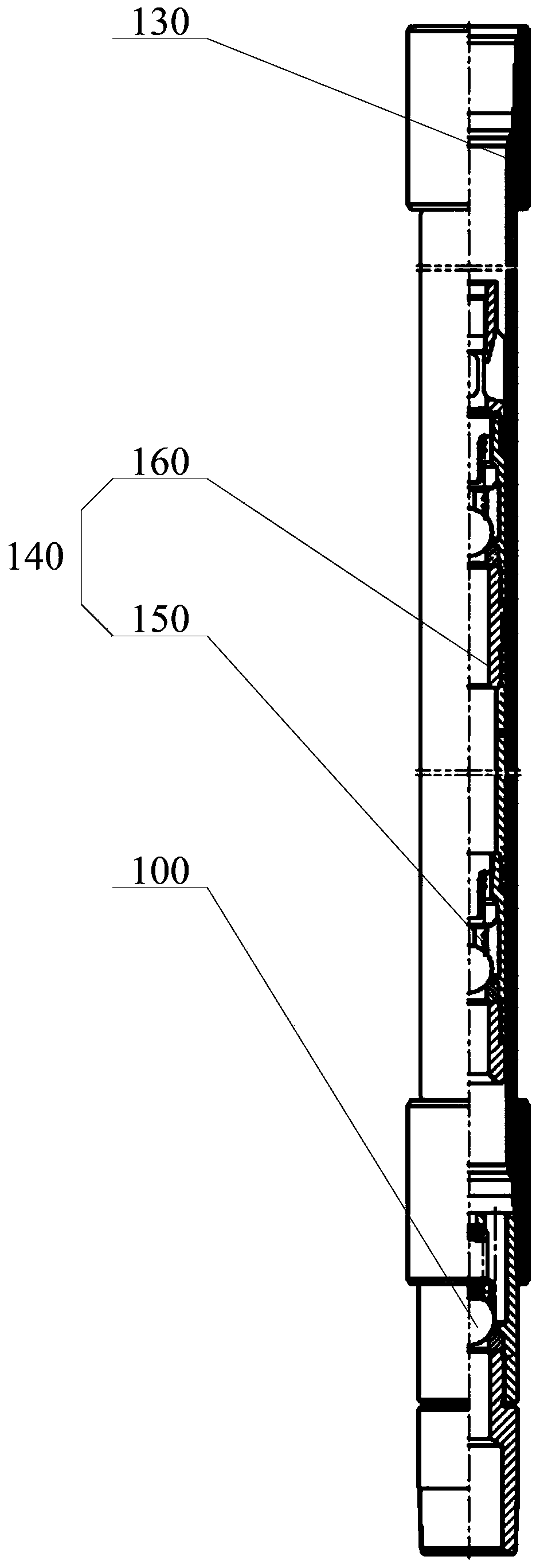

[0036] like Figure 1-Figure 2 As shown, the forced closing suction valve 100 provided in this embodiment includes: a first valve cover 200, a first return spring 300, a first valve ball 400 and a first valve seat 500; the first valve seat 500 is arranged on the second Inside a valve cover 200, abuts against one end of the first valve cover 200, and forms a first accommodating space between the first valve seat 500 and the first valve cover 200, the first return spring 300 and the first valve ball 400 are all located in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com