Automatic Compensation Sealed Packing Box

An automatic compensation, packing box technology, applied in the directions of sealing/packing, wellbore/well components, earth-moving drilling, etc. The effect of preventing the infiltration of rainwater or sewage, improving the sealing ability, and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

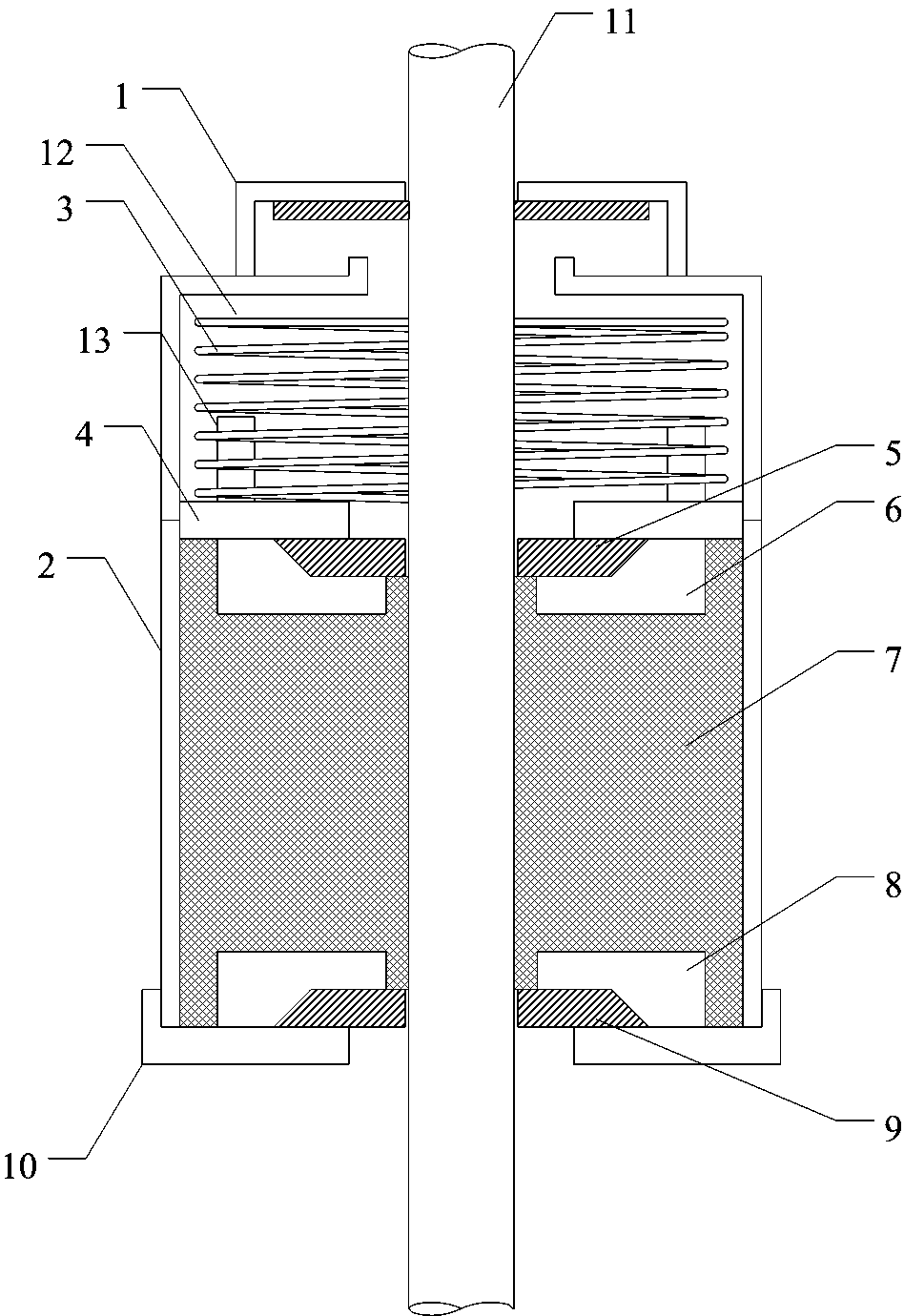

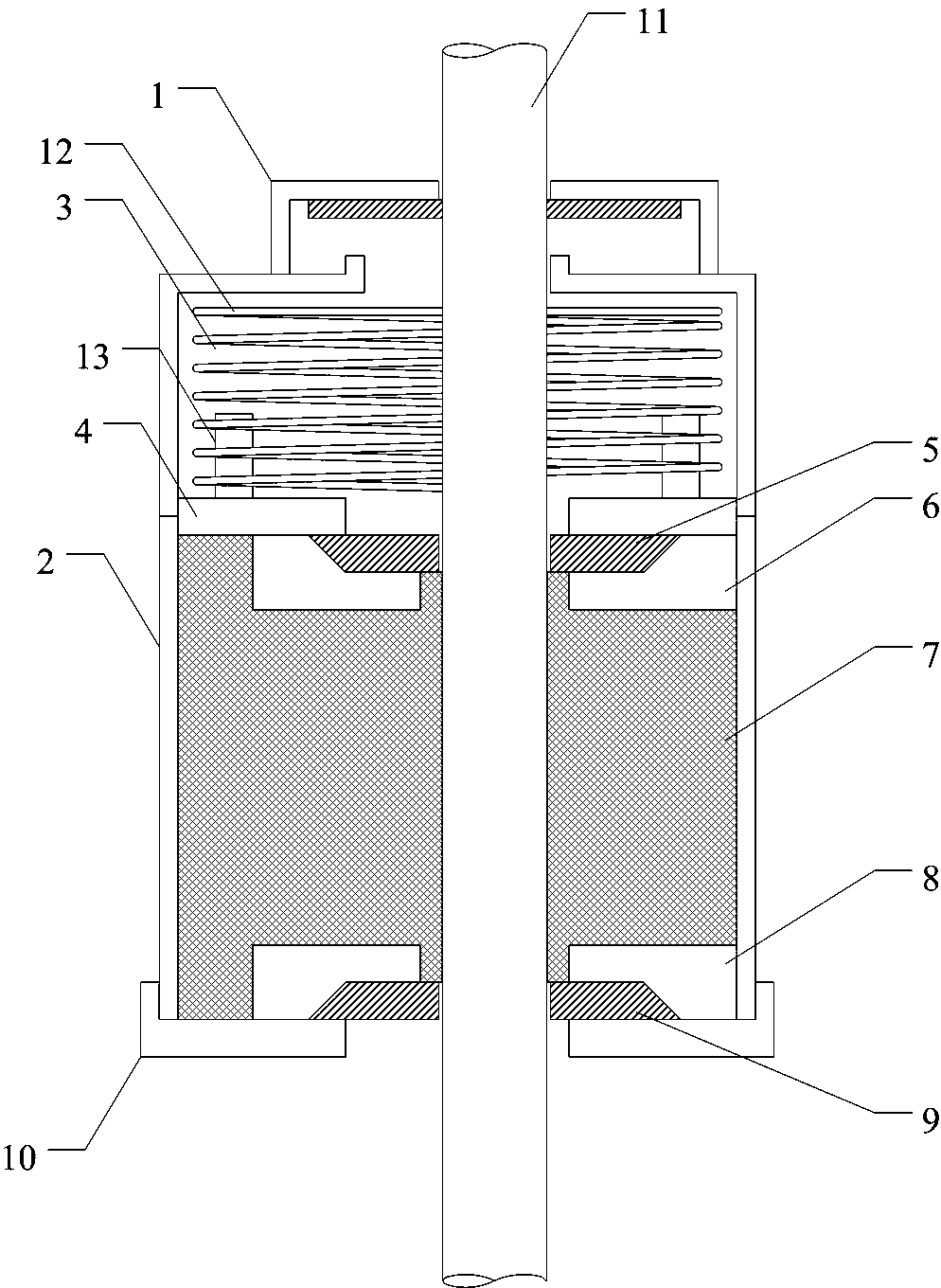

[0030] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0031] Such as figure 1 As shown, the self-compensating sealed packing box includes a sealed cover (1), a sealed casing (2), a compensation spring (3), a pressure plate (4), a first righting packing (5), a first righting pressure piece (6), compensating packing (7), second righting pressure piece (8), second righting packing (9), sealing base (10), and there are round holes in the middle, and the polished rod (11) passes through the round hole through;

[0032] Depend on figure 1 It can be seen that the sealing cover (1) is tightly connected with the upper part of the sealing shell (2), and the distance is adjustable, and the compensation spring (3) is clamped between the sealing cover (1) and the pressing plate (4), and a space is formed between the sealing cover (1) and the pressing plate (4). Cavity (12), lubricating oil is injected into the cavity (12), and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com