Method for positioning annular framework type sieve tube segment

A positioning method and a skeleton technology, which is applied in earthwork drilling, measurement, borehole/well components, etc., can solve the problems that the uranium well screen section cannot be accurately lowered to the position of the mine layer, and the error cannot be controlled, so as to achieve long operation period , easy operation, and the effect of enhancing oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

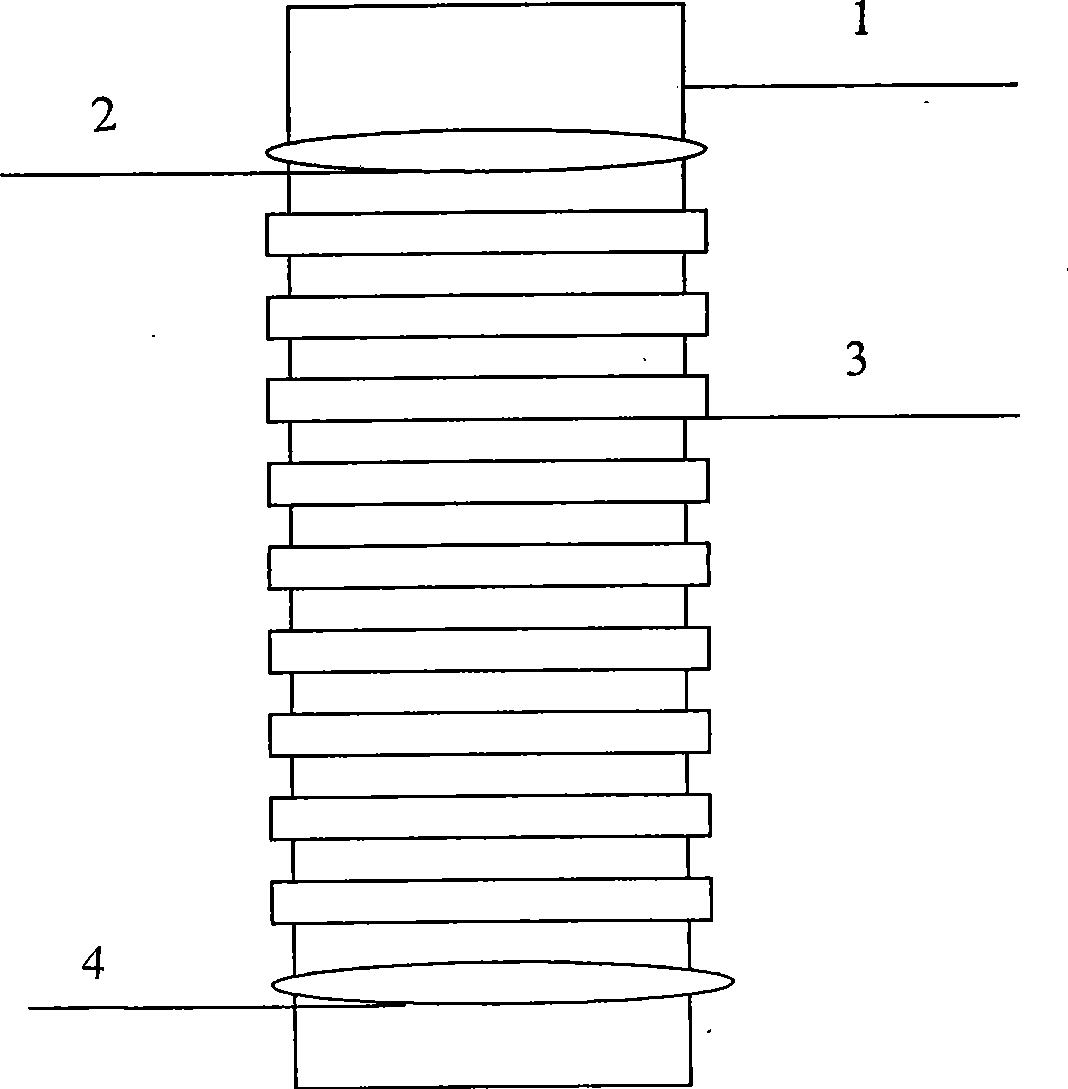

[0008] The positioning method of the ring-frame screen section is realized by the ring-frame screen positioning device. In the attached drawing, the device consists of a casing 1, an iron ring 2 at the upper end of the screen pipe, an annular skeleton screen pipe 3, and an iron ring at the lower end of the screen pipe. Composition of ring 4: According to the logging curve, determine the position of the ore seam, calculate the correct position of the screen section, and then determine the length of the screen section; drill 4-8 rows of staggered round holes with a diameter of 12-14mm at the corresponding position of casing 1 , the hole distance is 6-8cm, and the circular skeleton screen pipe 3 made of PVC pipe is installed outside the round hole of the casing pipe 1. The upper edge of the screen pipe 3 is covered with three iron rings 2 at the upper end of the screen pipe with a diameter of 3-6mm. , the lower edge of the screen pipe 3 is covered with three iron rings 4 at the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com