Oil guide structure of range hood

A technology of a range hood and an oil guide plate, applied in the field of range hoods, can solve the problems of condensing oil fume into oil droplets and affecting user experience, and achieve the effects of ensuring use hygiene, improving user experience, and avoiding the backflow of oil fume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

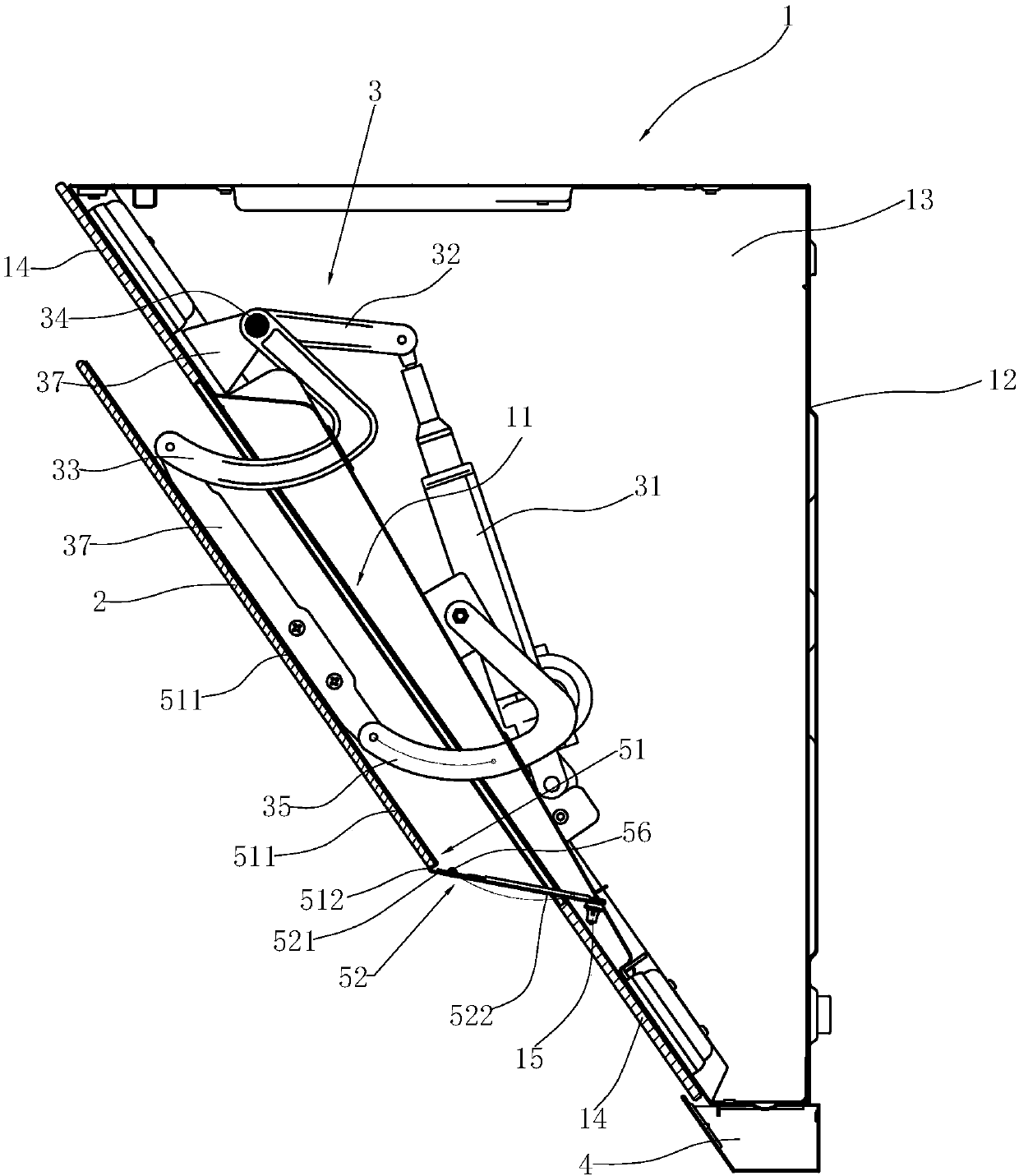

[0038] like Figure 1 to Figure 3 As shown, the oil guide structure of the range hood includes:

[0039] The smoke collecting hood 1 includes a backboard 12 , side panels 13 connected to both sides of the backplane 12 , and a front side panel 14 obliquely connected between the side panels 13 and on the backplane 12 , and the panel 14 is provided with an air inlet 11 .

[0040] The rectifying plate 2 is used to guide the oil fume, and is obliquely arranged on the front side of the fume collecting hood 1 corresponding to the air inlet 11 on the fume collecting hood 1; the angle between the rectifying plate 2 and the horizontal plane is 30-50°, In this embodiment, it is 40°.

[0041] The driving mechanism 3 is connected to the smoke collecting hood 1, connected to the rectifying plate 2, and used to drive the rectifying plate 2 to move so as to open or close the air inlet 11; including:

[0042] Driving device 31, can have multiple, present embodiment adopts electric push rod; ...

Embodiment 2

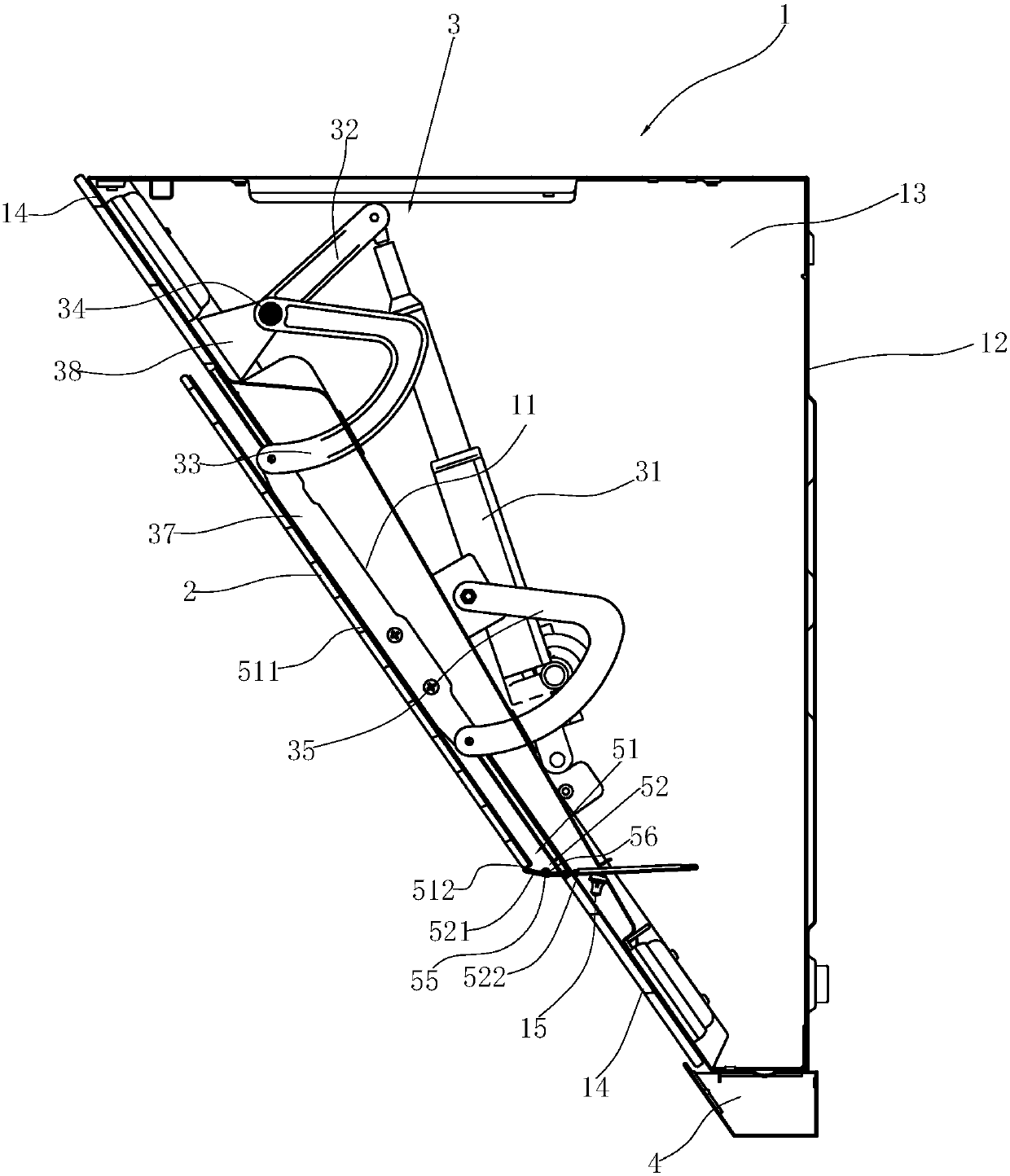

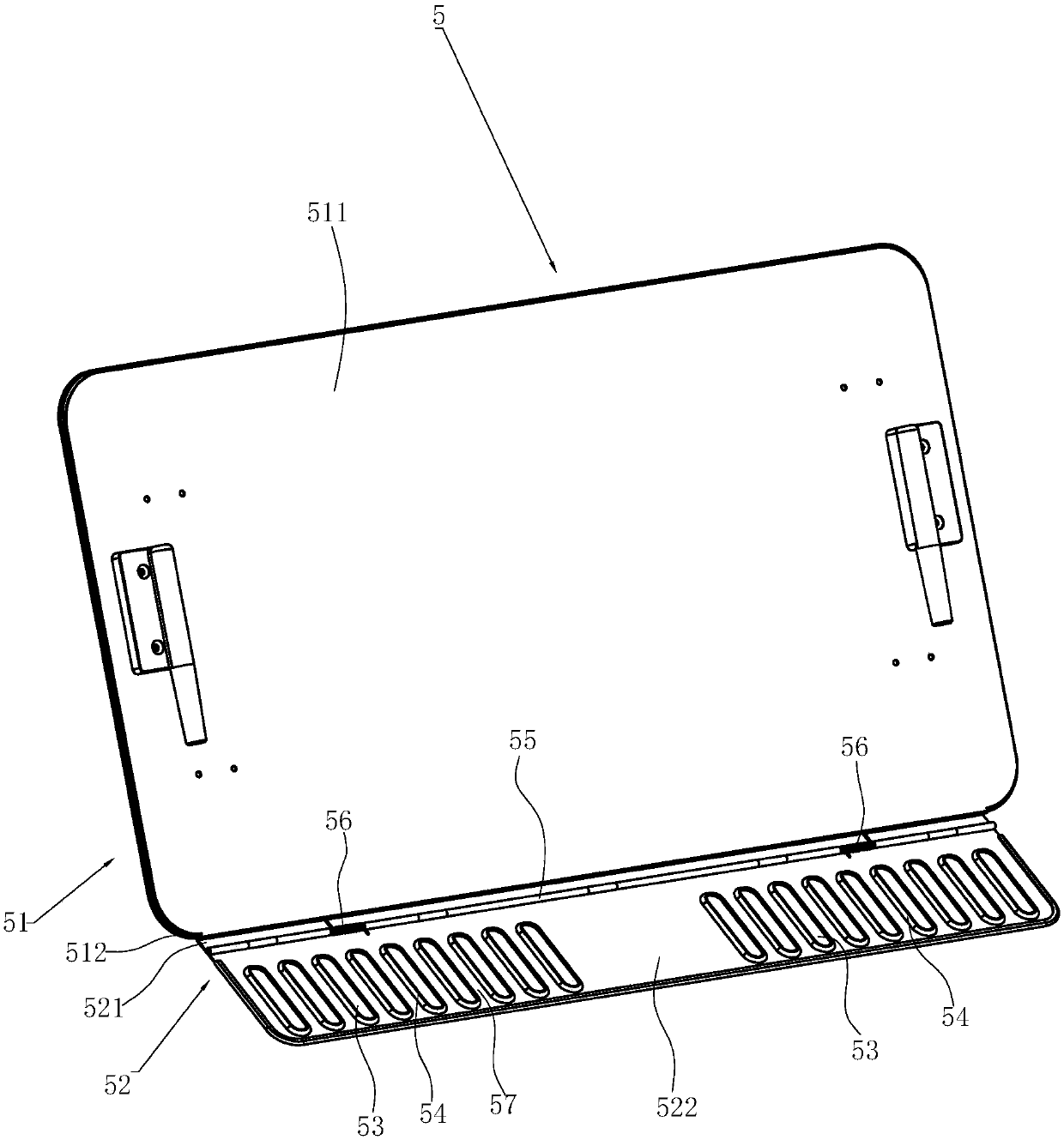

[0059] Such as Figure 4 with Figure 5 As shown, compared with Embodiment 1, this embodiment does not set a limit block, but a third crank 36 is hinged on the second crank 35, and the specific description is as follows:

[0060] There are two third cranks 36 , which are respectively connected to two second cranks. One end of the third crank is hinged on the handle body of the second crank 35 , and the second end of the third crank 36 is hinged to the second connecting plate 522 .

[0061] When the range hood is working, the movement of the second crank drives the movement of the third crank at the same time, and the end position of the connecting plate is limited by the third crank, so that the oil on the second connecting plate drops onto the inner surface of the fume collecting hood panel or directly Drops into the oil cup; when the rectifying plate is closed, the third crank pulls the second connecting plate to turn over. After the rectifying plate is closed in place, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com