An improved structure of the oil injection nozzle of an oil injection machine

A technology of oil injection nozzle and oil injection machine, which is applied in the direction of engine lubrication, mechanical equipment, engine components, etc. It can solve the problems of oil dripping easily, achieve the effects of preventing falling, increasing the length of the edge line, and increasing the pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

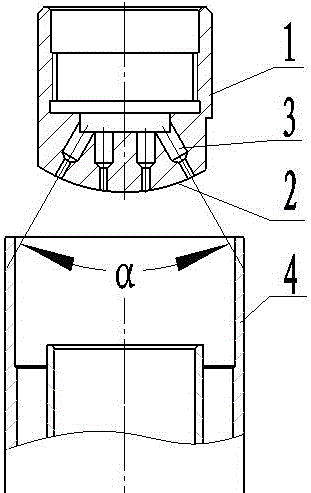

[0020] Such as figure 1 As shown, the improved structure of the oil injection nozzle of the oil injection machine in the present invention includes an oil injection nozzle body 1, the oil injection nozzle body 1 is cylindrical, and has a cylindrical cavity inside, and the cavity is used as an injection channel for shock absorbing oil. Both ends of the oil nozzle body are open, one end is used to communicate with the oil injection machine, and the other end is inserted into the interior of the shock absorber 4 as an oil outlet. The oil outlet of the oil injection nozzle body 1 forms a closed end 2, The outside of the closed end 2 is arc-shaped, and then a plurality of through holes 3 are arranged on the closed end 2, the axes of the through holes 3 are perpendicular to the arc surface of the closed end 2, and the through holes 3 have two inner cylindrical cavities with different diameters. The two cylindrical cavities are connected by a tapered surface to form a stepped structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com