Closestool cover plate assembly and dismounting mechanism thereof

A disassembly mechanism and panel assembly technology, which is applied to toilet seats or covers, household utensils, sanitary equipment, etc., can solve the problems of limited impact force, easy loosening, poor firmness, etc., and achieve improved lateral movement resistance The effect of ability, structural stability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

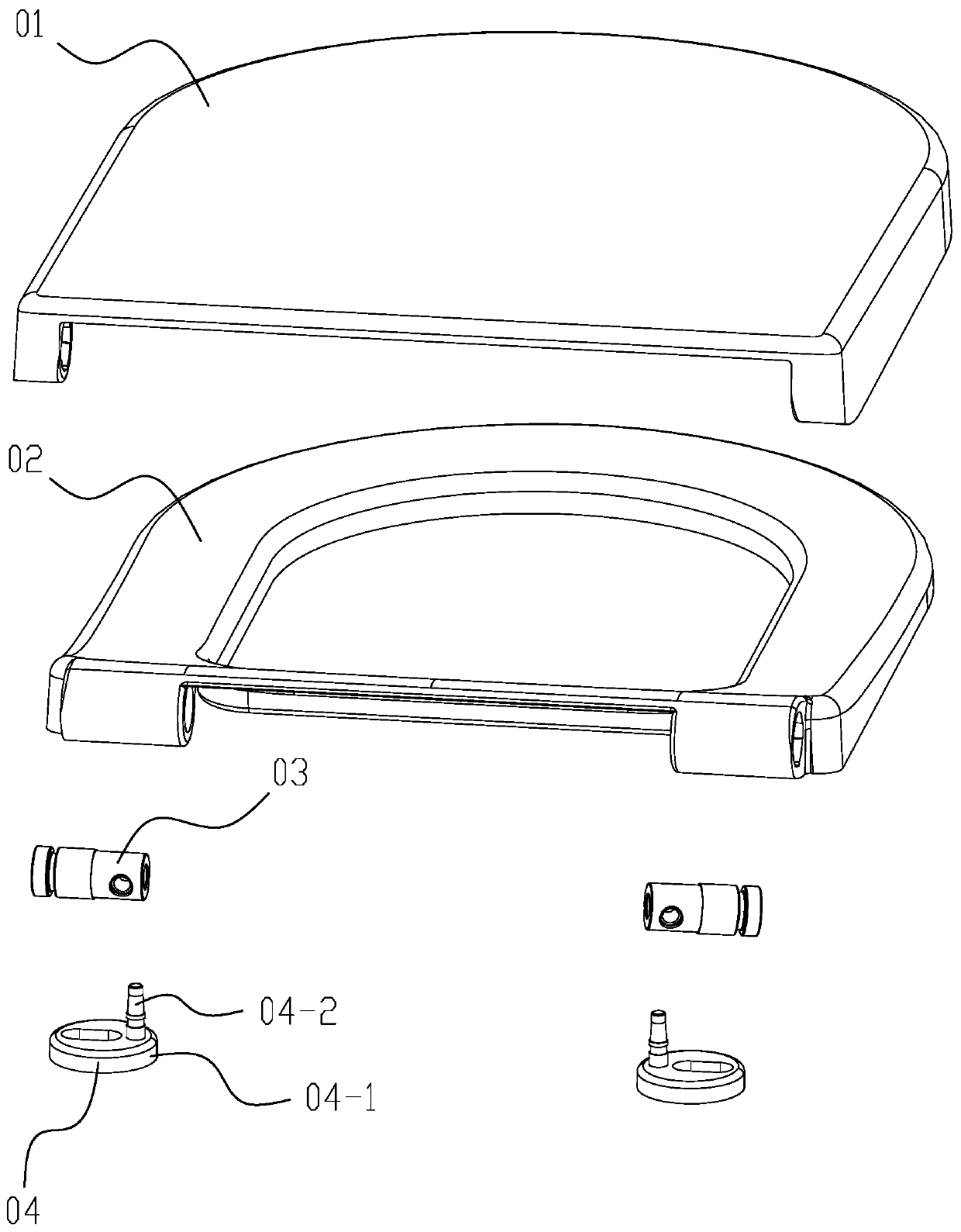

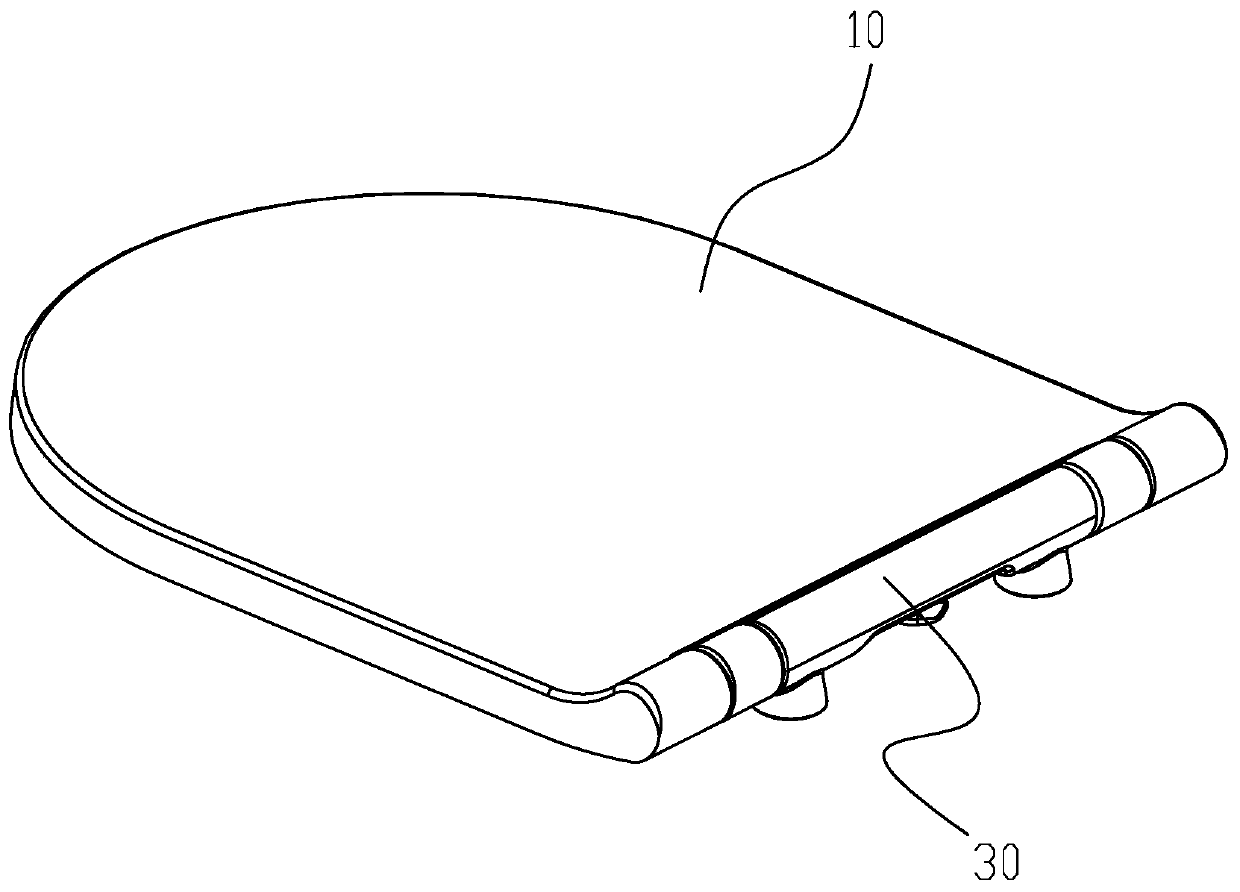

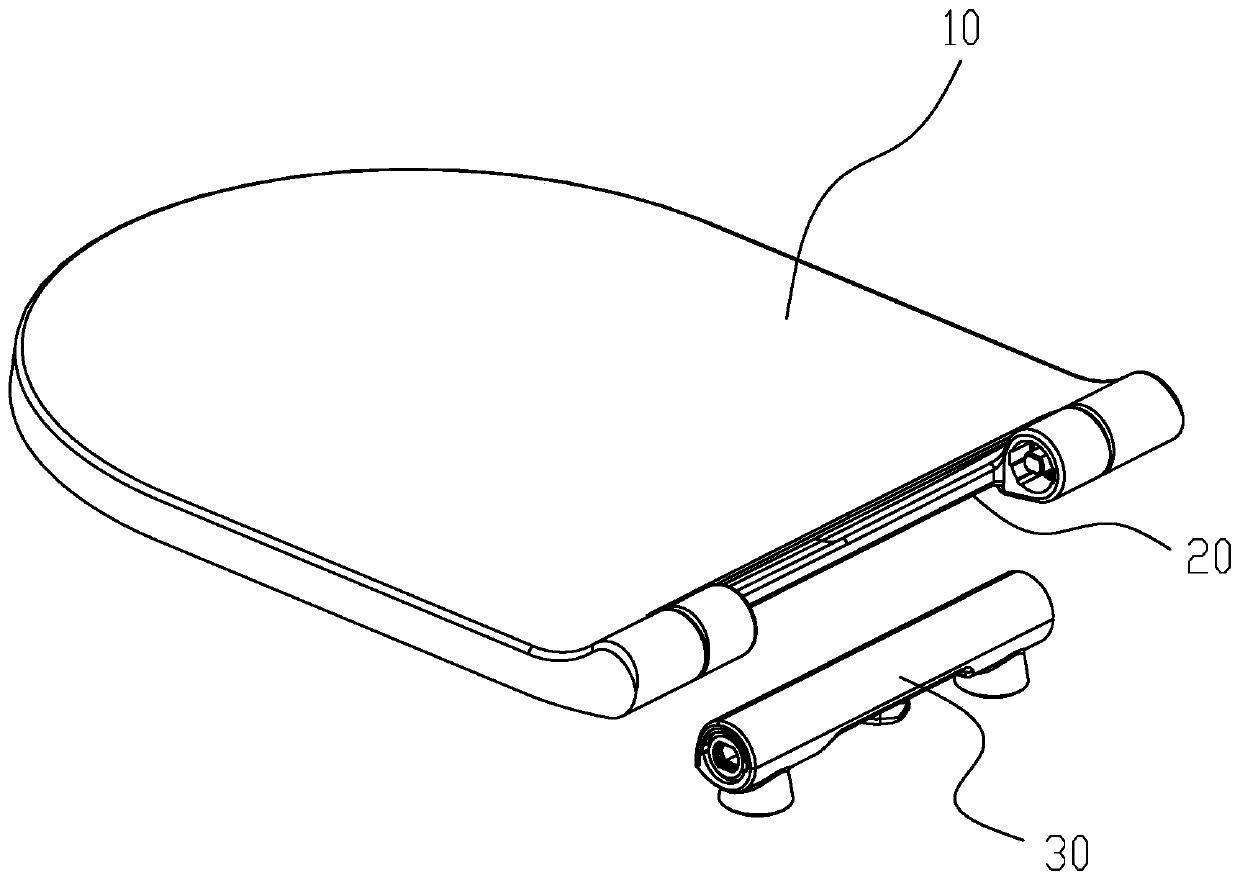

[0019] Please refer to figure 2 with image 3 , the toilet cover assembly includes a loam cake 10, a seat ring 20 and a dismounting mechanism 30, the connecting parts on both sides of the rear end of the loam cake are respectively connected with the connecting parts on both sides of the rear end of the seat ring, the loam cake 10 and the seat ring 20 are combined into a whole and plugged together with the dismounting mechanism 30 or disengaged.

[0020] Please refer to Figure 4 with Figure 5 The dismounting mechanism 30 includes a shaft sleeve 31, which is locked on the toilet body 40 by two bolts 32, and the two ends of the shaft sleeve 31 are symmetrically provided with mounting holes 312 vertically penetrating in the radial direction. The bolt 32 passes through the installation hole 312 from top to bottom to lock with the toilet body 40 . The dismounting mechanism 30 also includes two connecting shafts 33 arranged in the bushing and capable of reciprocating axially l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com