Fancy loop-pile yarn with various patterns and manufacturing method of fancy loop-pile yarn

A production method and fancy technology, applied in the field of yarn, can solve the problems of low efficiency, increased production cost, lack of diversity, etc., and achieve the effects of high efficiency, low production condition requirements, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further explain the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

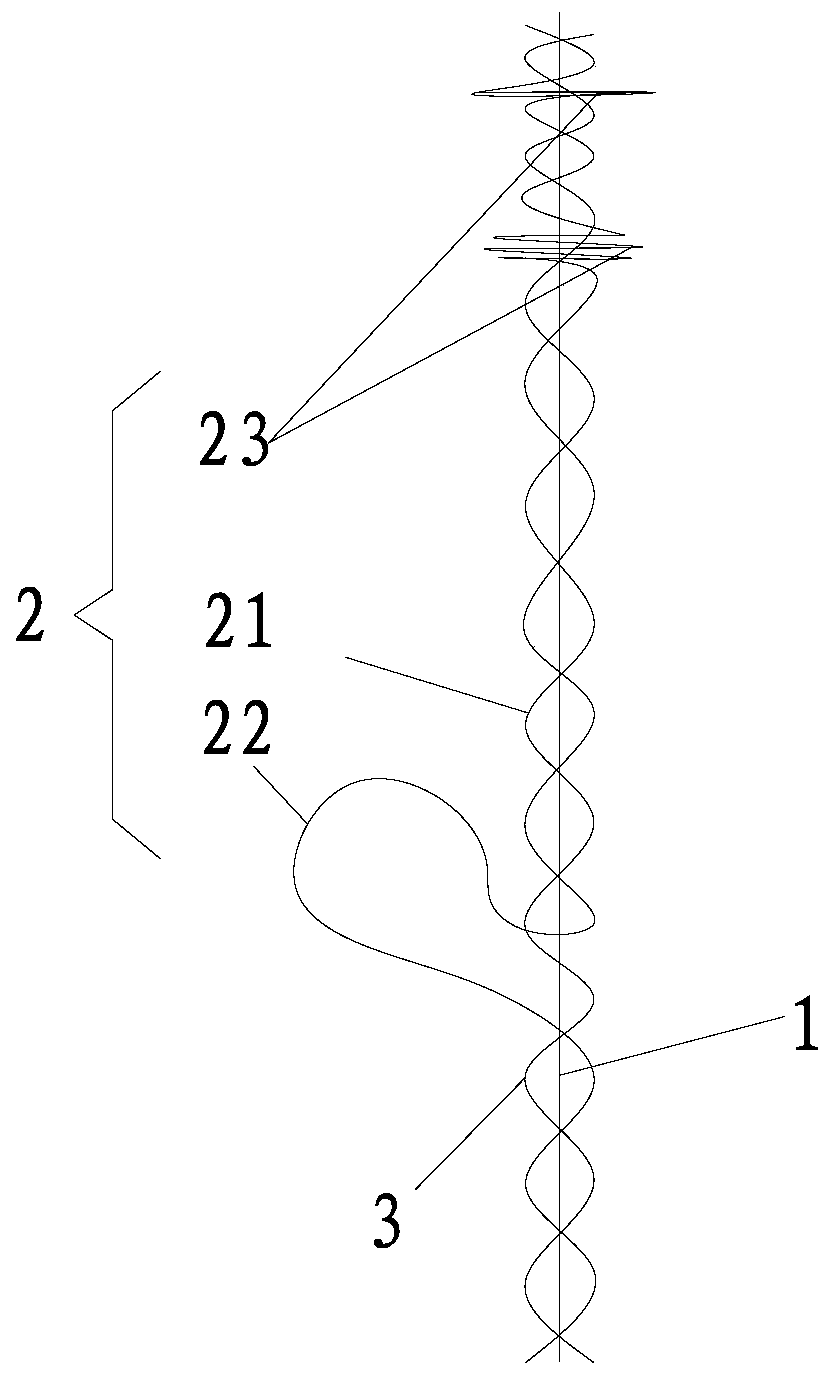

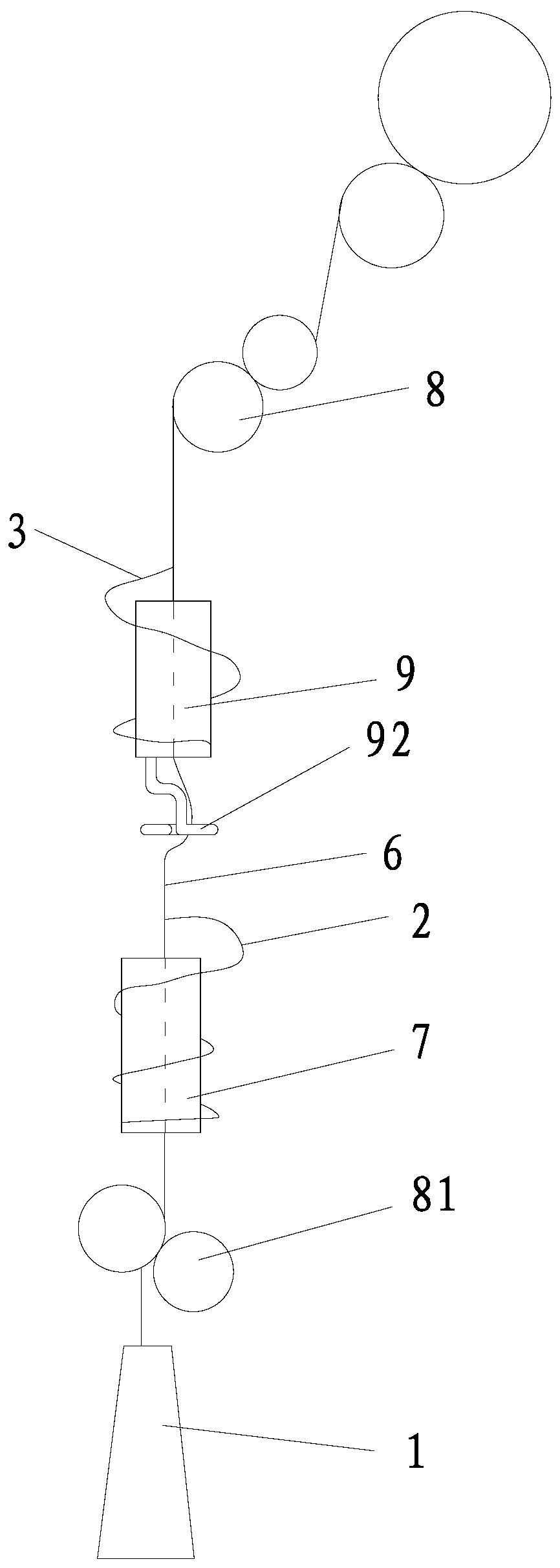

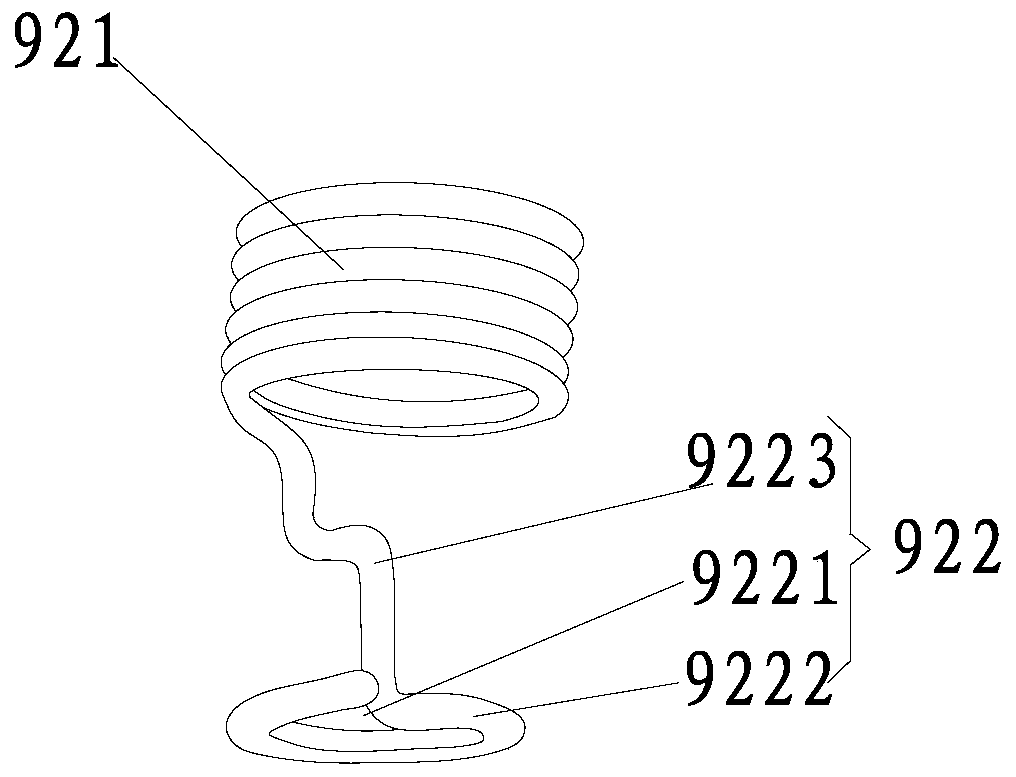

[0038] A kind of fancy loop pile yarn with multiple pattern of the present invention, as figure 1 As shown, it includes a yarn body, the yarn body includes a core thread 1, a decorative yarn 2 and a fixed yarn 3, the decorative yarn 2 is wound around the core thread 1, and the decorative yarn 2 extends spirally in the axial direction and is wound around the core thread in a twisted manner 1, the decorative yarn 2 includes a spiral part 21, a coil part 22 (that is, the loop structure on the conventional fancy loop pile yarn) and a convex hull part 23 (that is, the slub structure on the conventional fancy loop pile yarn), and the decorative yarn The yarn 2 is wound around the core wire 1 to form a helical part 21, and the fixed yarn 3 spirally extends in the axial dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com