Photographic processor

A film processor and photographic film technology, applied in the direction of mechanical transmission of exposure materials, liquid processing, photosensitive materials, instruments, etc., can solve the problems of low-efficiency use of processing liquid, damage to processing equipment, liquid overflow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

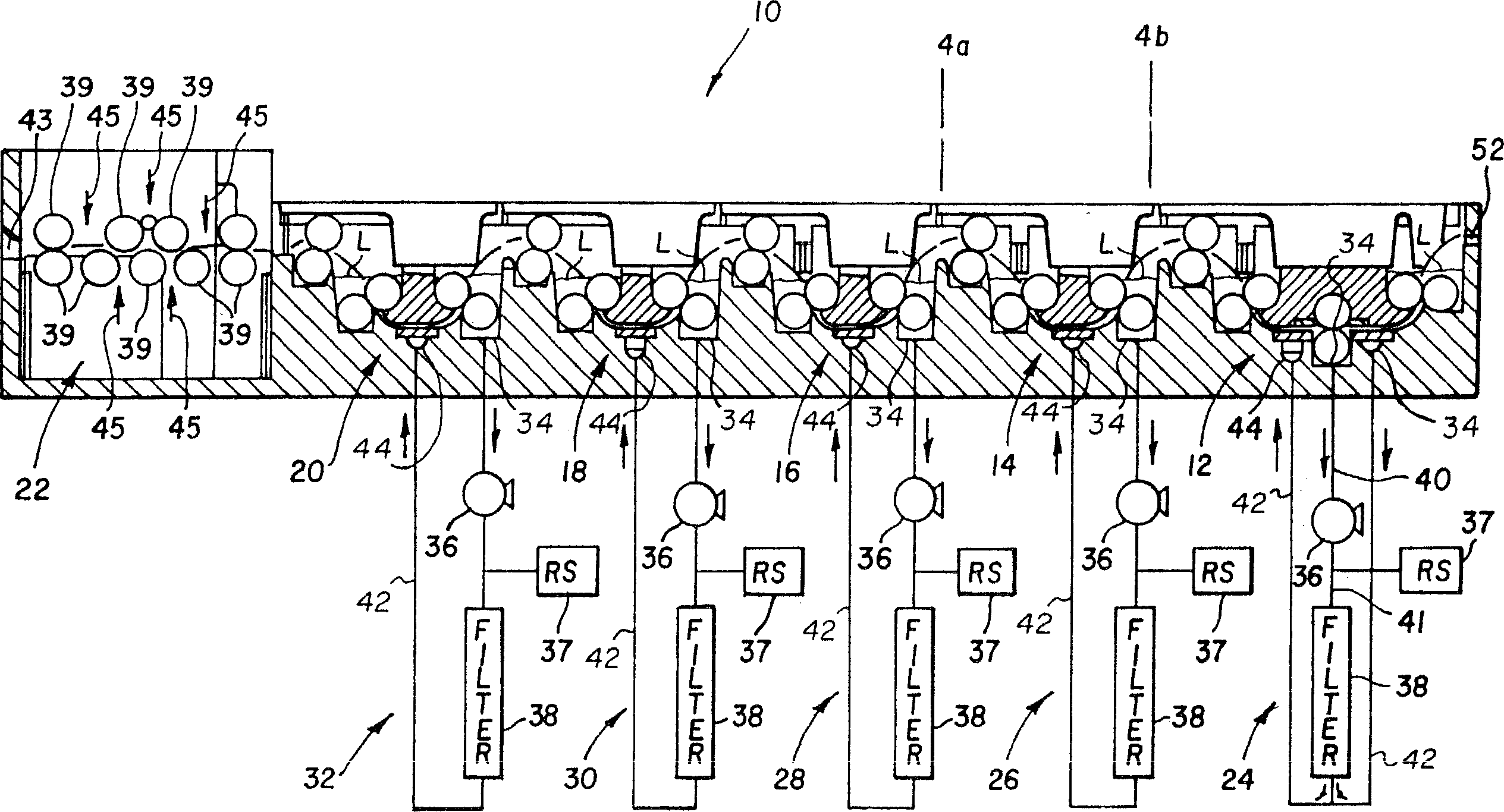

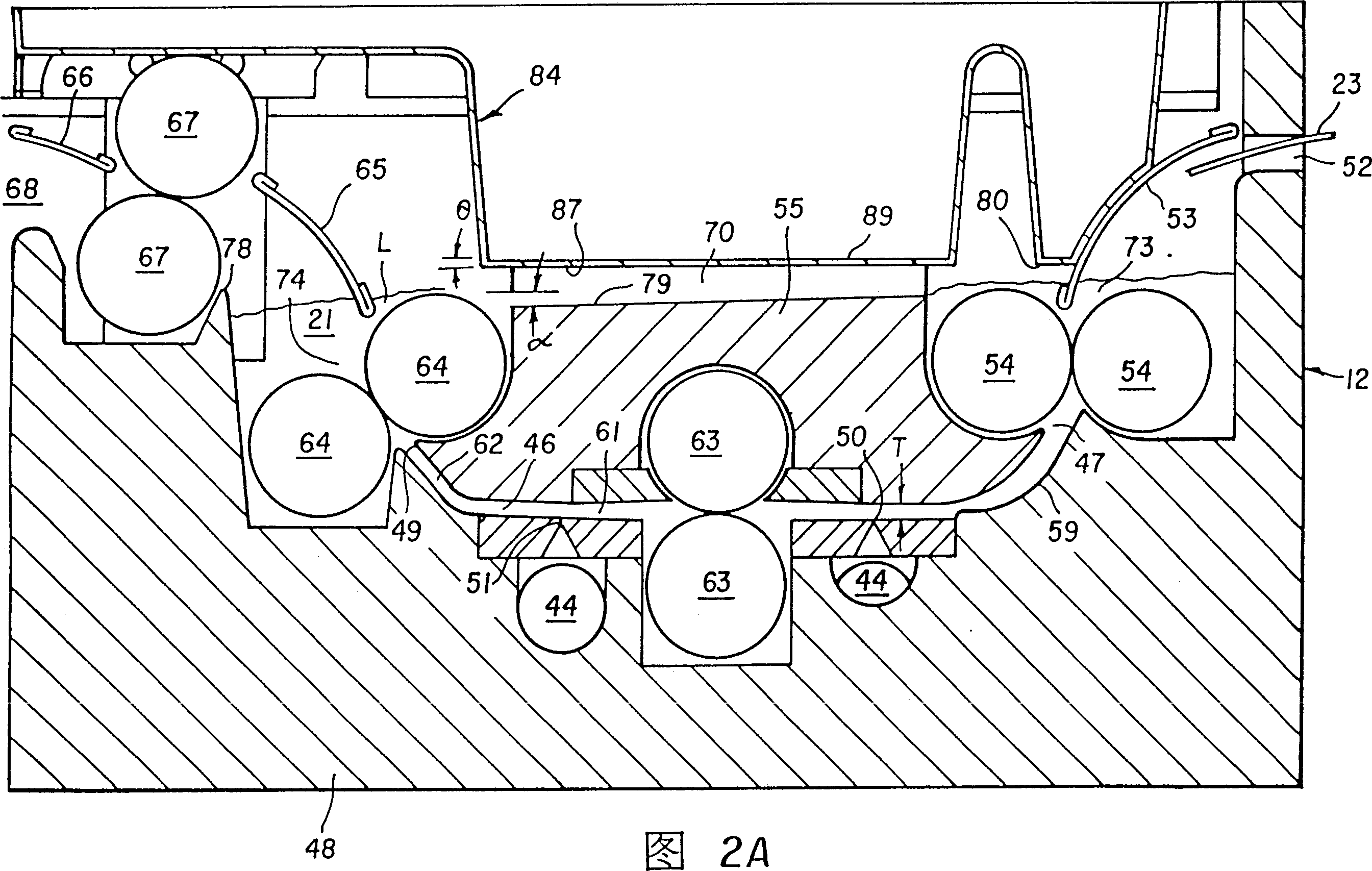

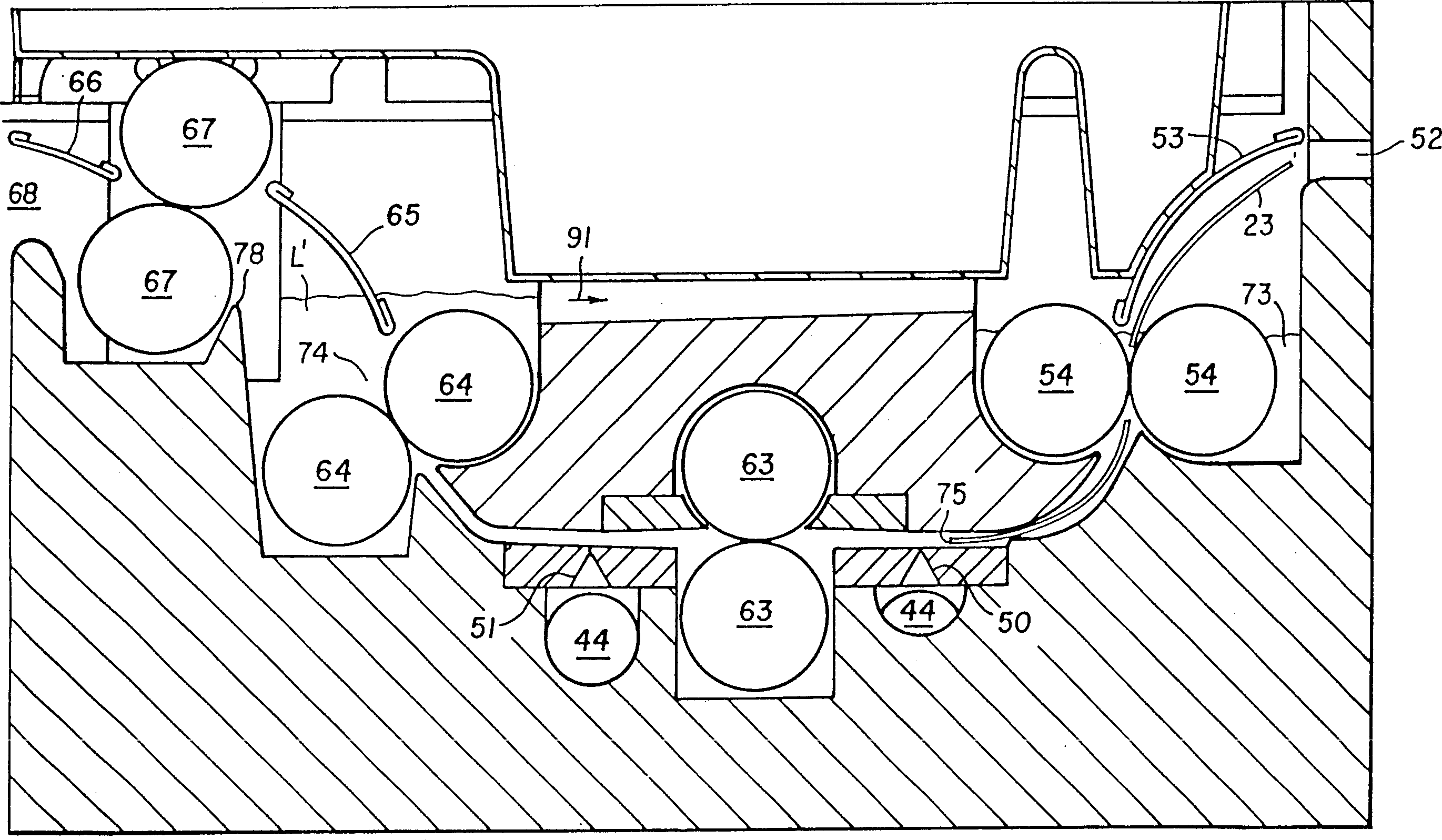

[0017] see figure 1 , shows a film processor 10 made according to the present invention. The film processor includes a plurality of processing sections 12, 14, 16, 18, 20, each processing section is used to hold a processing solution 21 for a photosensitive article 23 passing through the section (see Figure 2B ) for flushing. In the particular embodiment shown, processing section 12 contains a developing processing solution; processing section 14 contains a bleach-fix processing solution; and processing sections 16, 18, 20 each contain a stabilizing Agent flushing liquid. The liquid level of the rinsing liquid in each rinsing part is represented by the letter L. The dryer 22 is provided for drying the photosensitive article 23 after the photosensitive article 23 is discharged from the last processing section 20 .

[0018] Dryer 22 includes a plurality of rollers 39 for guiding and transporting photosensitive article 23 through dryer 22 . A suitable mechanism (which is we...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap