A prefabricated building anti-seismic structure using cement prefabricated components

A technology of prefabricated components and anti-seismic structures, which is applied in the direction of protective buildings/shelters, buildings, building types, etc., and can solve problems such as poor shock absorption effect and lack of shock absorption structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

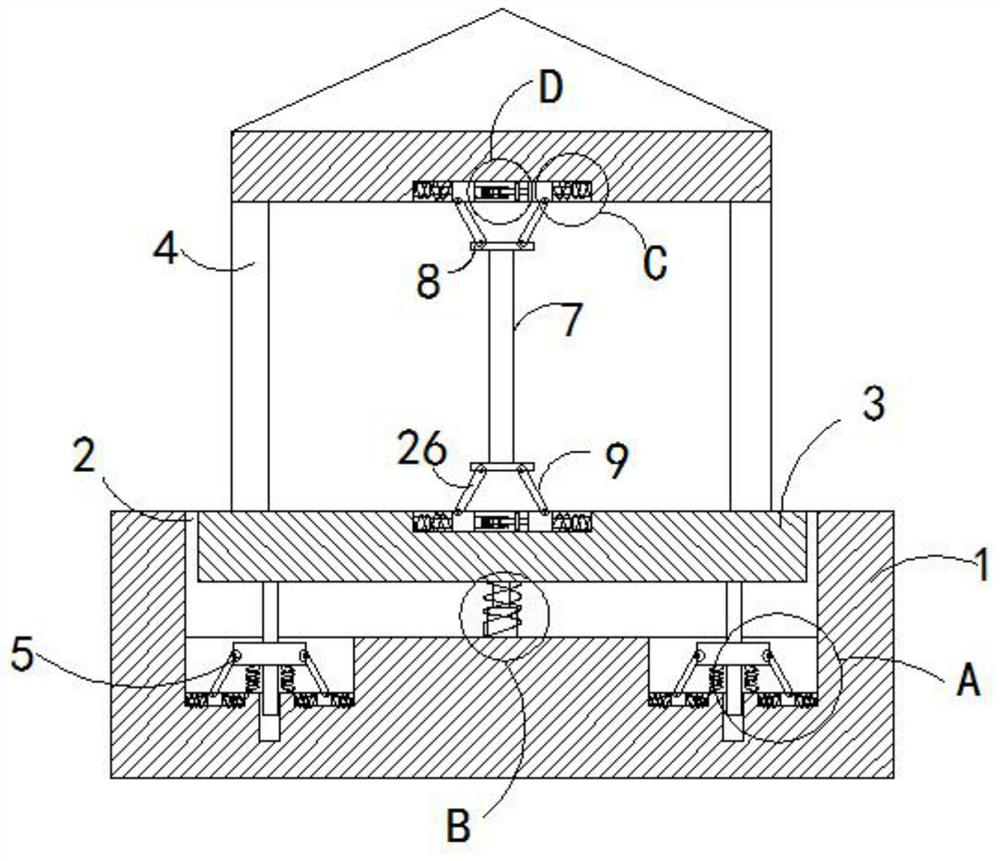

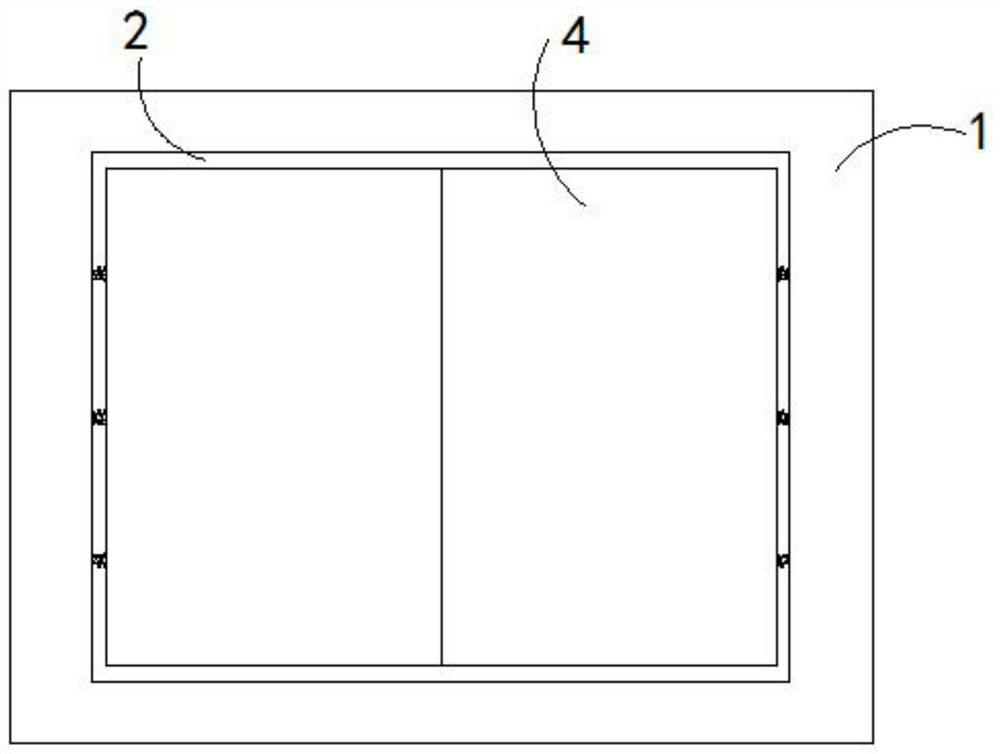

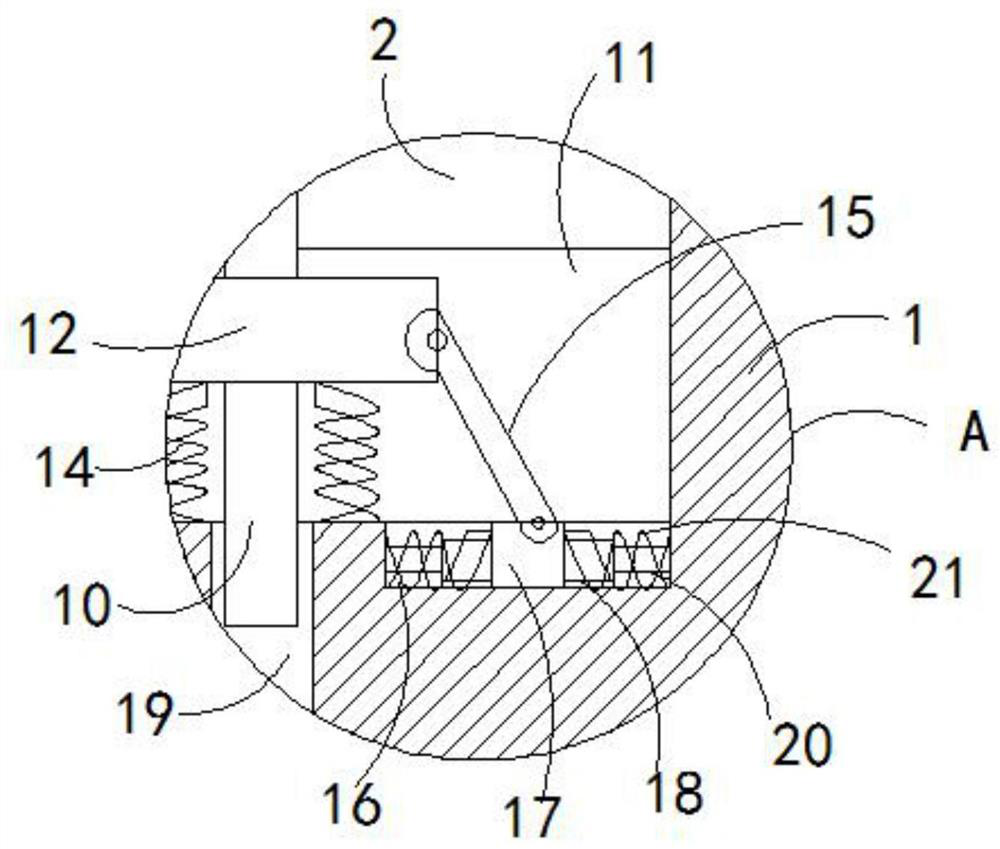

[0028] Such as Figure 1-6 As shown in the figure, a prefabricated prefabricated building structure using cement components includes a base 1 to meet the construction needs. The upper end of the base 1 is provided with a first groove 2, and the first groove 2 is provided with a bottom plate 3 , the upper end of the base plate 3 is fixedly connected with the housing body 4, and the lower end of the base plate 3 is fixedly connected with a plurality of first damping devices 5 and a plurality of first elastic members 6, which can play the role of buffering and shock absorption, thereby protecting the prefabricated housing. , the lower end of the first elastic member 6 is fixedly connected to the bottom of the first groove 2. It should be noted that the first elastic member 6 can not only support the bottom plate 3, but also play a role of buffering and shock absorption. The housing body 4 is provided with a plurality of supporting columns 7, which can stabilize the housing body 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com