Directional hydraulic fracturing method based on concentrated energy blasting

A hydraulic fracturing and fracturing technology, which is applied in the field of directional hydraulic fracturing, can solve the problems of difficult directional treatment of local surrounding rock damage, stress disturbance of coal and rock mass, and inability to control the direction of crack propagation in holes, so as to reduce drilling costs. and labor intensity, increase the spacing of drilling holes, and save the effect of explosives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0028] Specific examples 1. The average thickness of 4 coal seams in a mine working face is 2.64m, the average inclination angle is 2°, and the hardness of the coal seam is f=2.7~3.7; the false roof is taupe sandy mudstone with an average thickness of 0.18m; the direct roof is gray siltstone , the structure is uniform, with an average thickness of 3.94m; the old roof is gray-white coarse sandstone, with an average thickness of 2.38m.

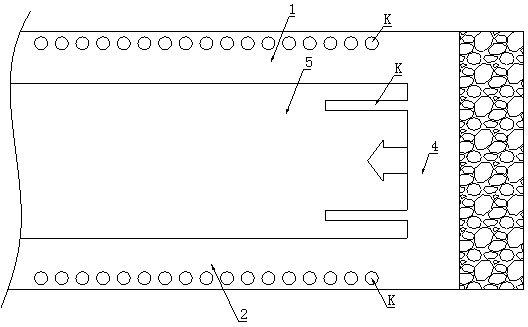

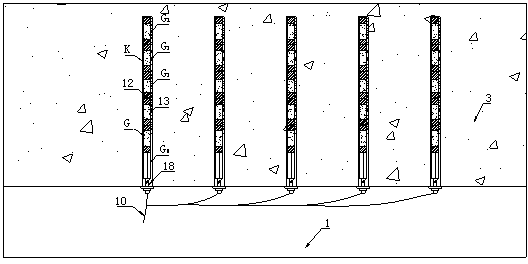

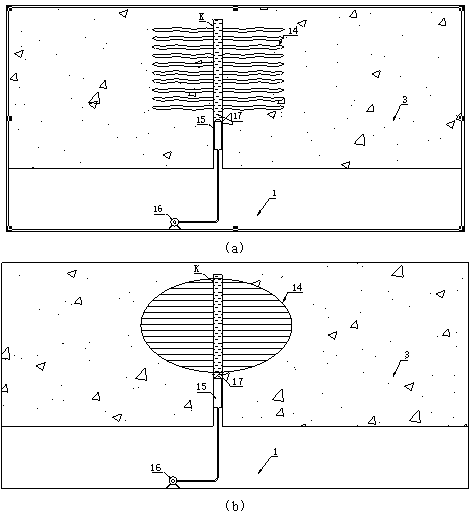

[0029] One fracturing borehole K is drilled above the oblique coal seam 5 at both ends of the working face 4, as Figure 4 As shown, the drilling diameter is 42mm and the hole depth is 9.2m. At the same time, on the 10m ahead of the working face of the machine lane 1 and the wind lane 2, the fracturing drilling K is constructed along the roof on the outer side of the two lanes, the diameter of the drilling hole is 42mm, the hole depth is 6.5m, and the drilling distance is 4m, and then advance along the working face 5 to 10 fracturing drill hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com