Operation detection method of hub bearing unit

A technology for wheel hub bearing and operation detection, which is used in mechanical bearing testing, measuring devices, instruments, etc., to achieve the effect of improving safety, compact structure, ensuring quality and reputation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

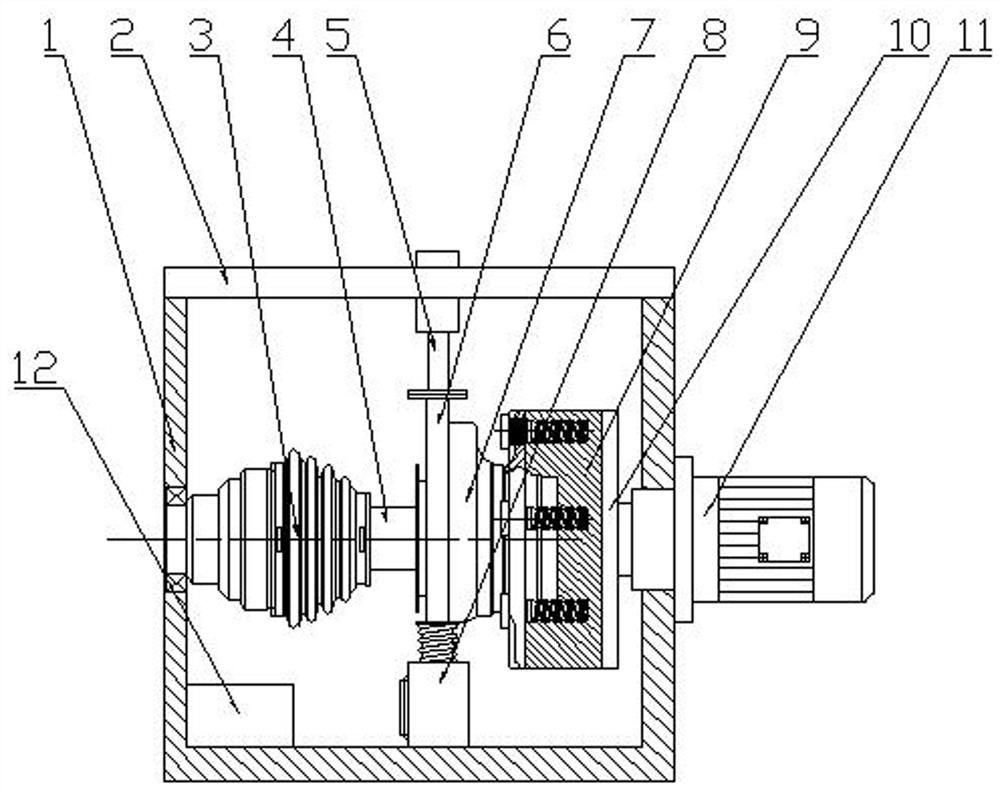

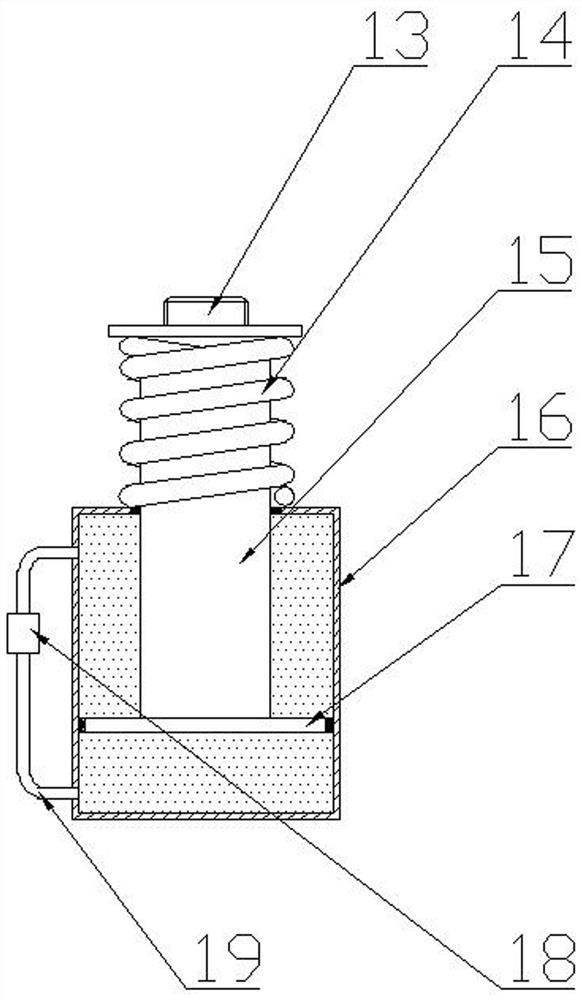

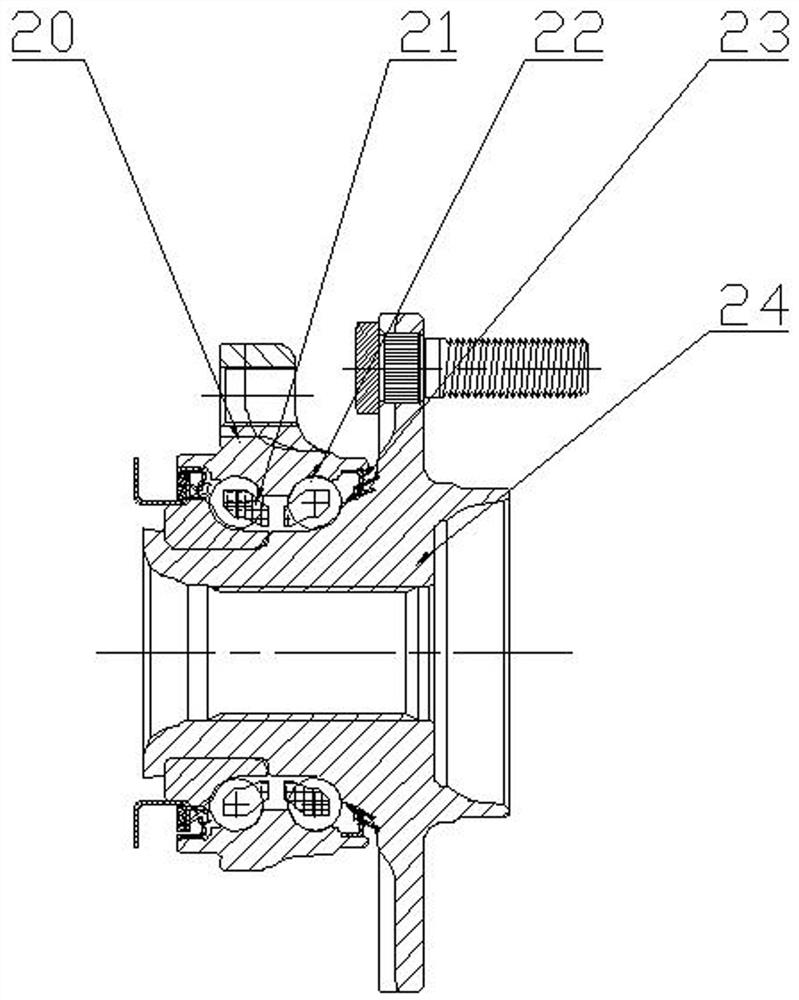

[0026] Example: such as figure 1 , figure 2 and image 3 As shown, a method for detecting the operation of a wheel hub bearing unit follows the following steps:

[0027] Step 1: During random inspection, the hub bearing unit 7 is first placed on the flaw detector to ensure that the inspected product has no processing defects. Then connect the wheel hub outer ring connecting flange 6 without processing defects through the rotating shaft 4 and the cushioning suspension simulation component 8, and then connect and fix the hub bearing unit 7 with the rotating shaft 4 in a splined socket first, and then connect with the wheel hub The outer ring connecting flange is 6-phase flange socket fixed, and at the same time, the bolt connection and fastening of the hub bearing unit 7 and the imitation hub connecting seat 9 are completed. The imitation wheel hub connection seat 9 adopts the motor connection flange plate 10 which is an integrated structure with the drive variable frequency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com