Motor and internal cooling structure thereof

A technology of internal cooling and cooling pipes, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve the problems of low-cost production, complex cooling structure, and unfavorable batch production, and achieve low leakage risk, High cooling efficiency and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

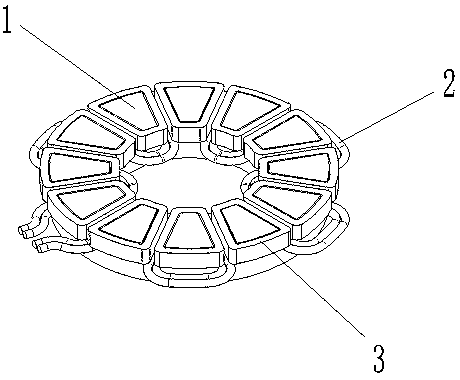

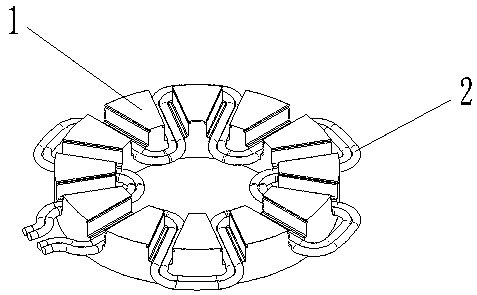

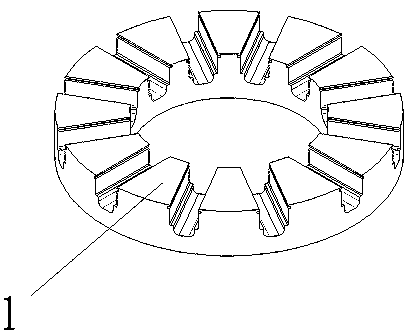

[0019] see Figure 1-Figure 4 , a motor and its internal cooling structure, which includes a stator core 1, a winding, a cooling pipe 2 coiled between the stator core 1 and the winding, and the cooling pipe 2 conducts heat directly to the stator core 1 and the winding.

[0020] see image 3 and Figure 4 , the stator core 1 is provided with a wire embedding groove 3, and the cooling pipe 2 is coiled radially and axially along the wire embedding groove 3 to form a cooling circuit.

[0021] see image 3 and Figure 4 , the stator core 1 is provided with a wire slot 3, and the cooling pipe 2 is pre-made in the same shape as the wire slot 3, and the cooling pipe 2 is fixed in the wire slot 3 Inside.

[0022] see image 3 , the cooling pipe 2 is one or two or more.

[0023] The cooling pipe 2 is a square structure.

[0024] The cooling pipe 2 is an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com