Bubbling stirring type cold crucible for vitrification and bubbling stirring method thereof

A technology of glass solidification and stirring method, which is applied in glass furnace equipment, glass manufacturing equipment, radioactive purification and other directions, can solve problems such as the setting of bubbling tubes, and achieve the effects of uniform temperature field distribution, reduced influence and short time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

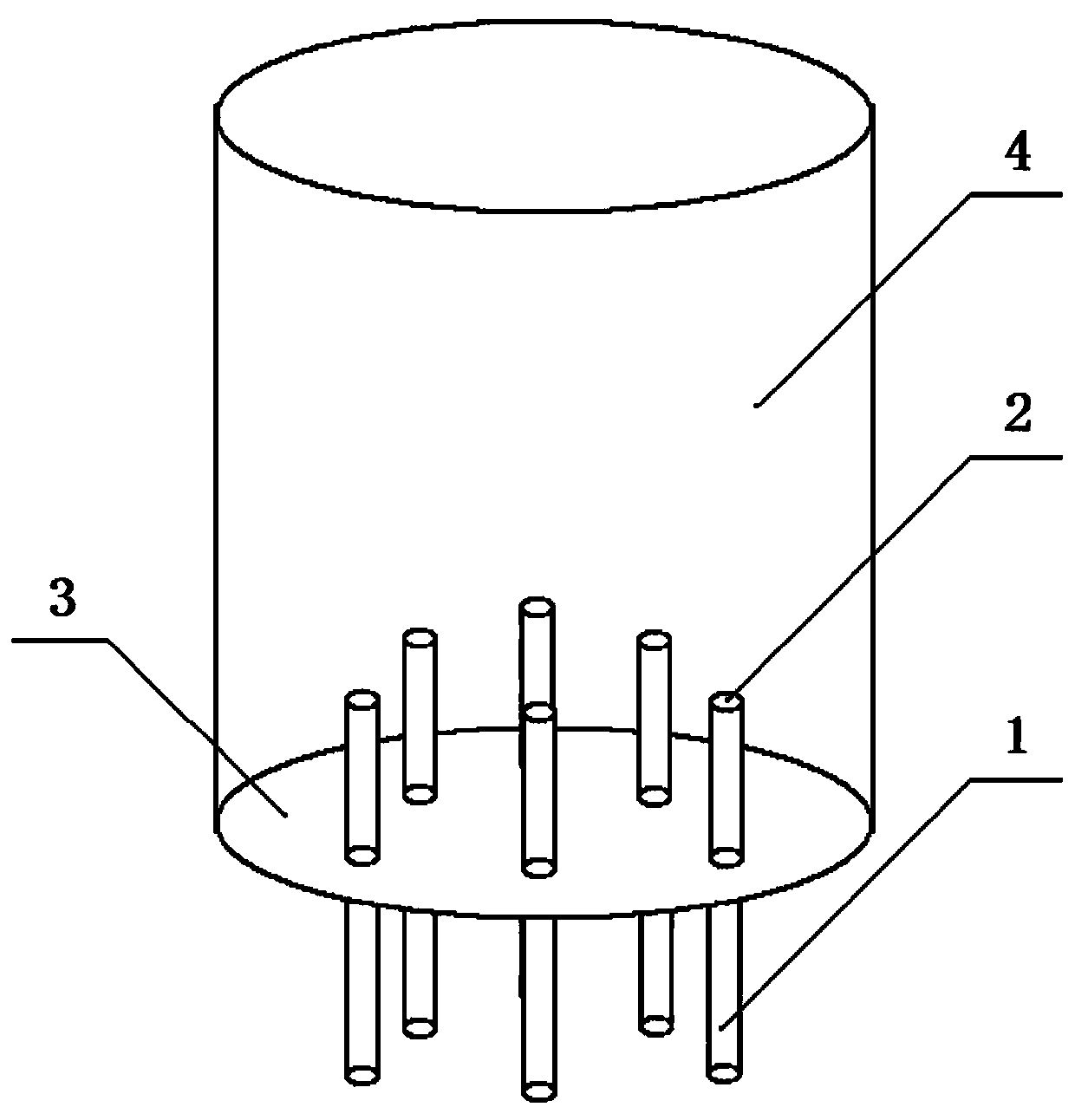

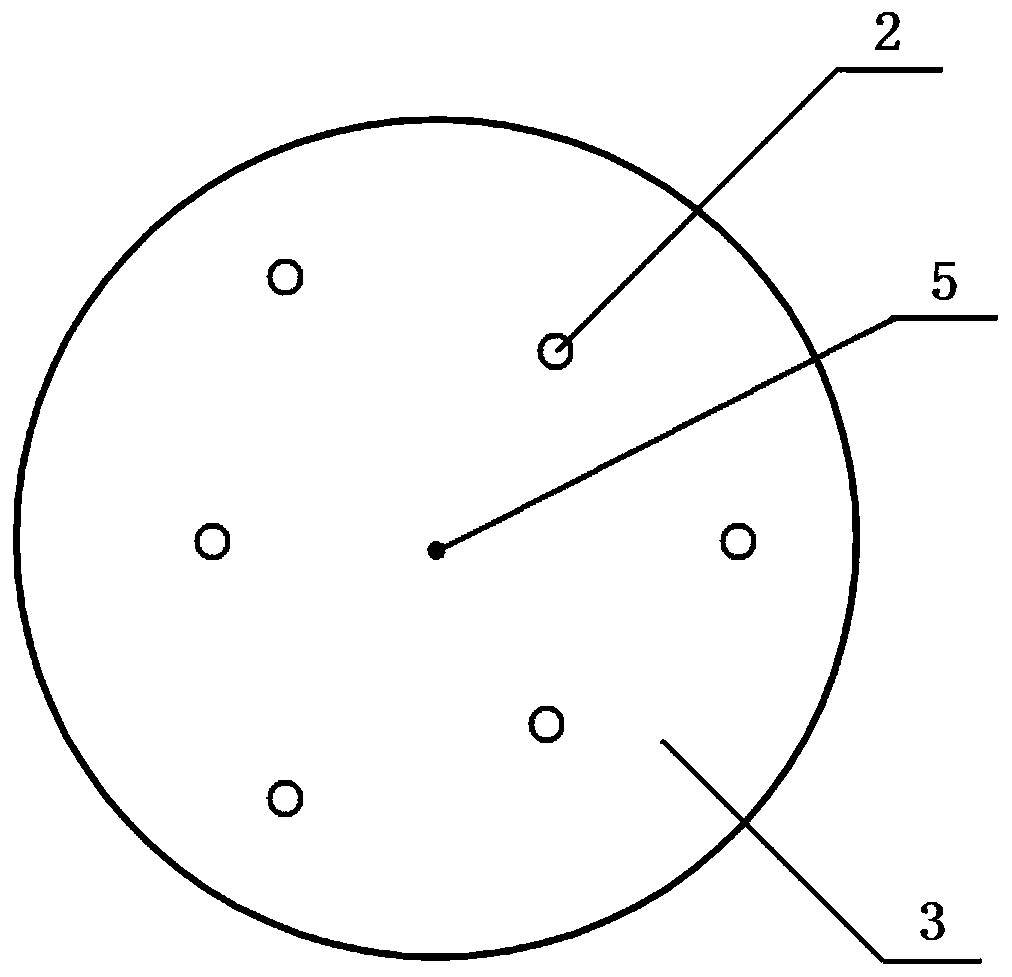

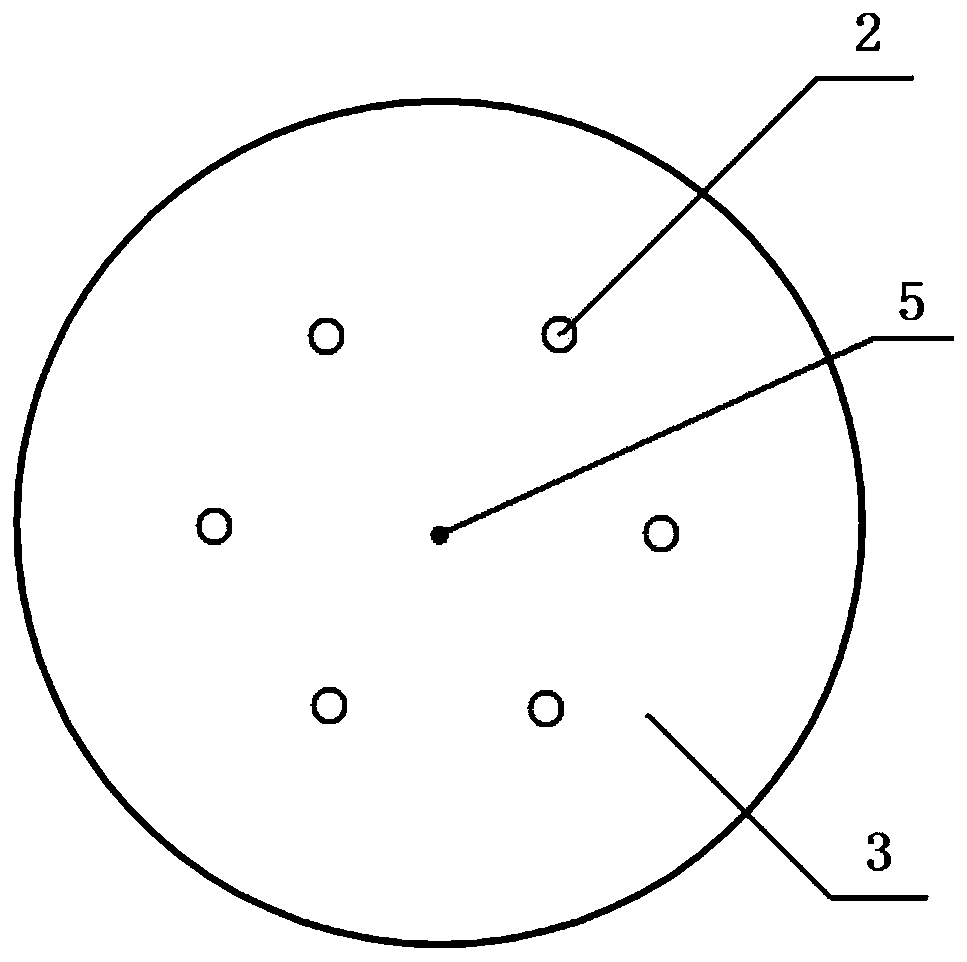

[0038] Adopt the bubbling stirring type cold crucible for vitrification of the present invention and the bubbling stirring method to stir a melt with a viscosity of 500dpa, the height of the cold crucible adopted is 800mm, the inner diameter is 500mm, and the number of bubbling tubes is 6 The distance between the opening of the three bubbling tubes inside the cold crucible and the center line of the cold crucible is 1 / 4 of the inner diameter of the cold crucible, and the distance between the openings of the other three bubbling tubes inside the cold crucible and the center line of the cold crucible is 1 / 3 of the inner diameter of the cold crucible, the height of each bubbling tube inserted into the crucible is 3cm, and the main process is as follows:

[0039] Use a gas compression pump to inject gas pulses into the melt through each bubbling tube for pulse bubbling, and the bubbling tubes that are close to the centerline of the cold crucible and the bubbling tubes that are far ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com