Heat exchanger with uniform furnace temperature

A heat exchanger, furnace temperature technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problem of low heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

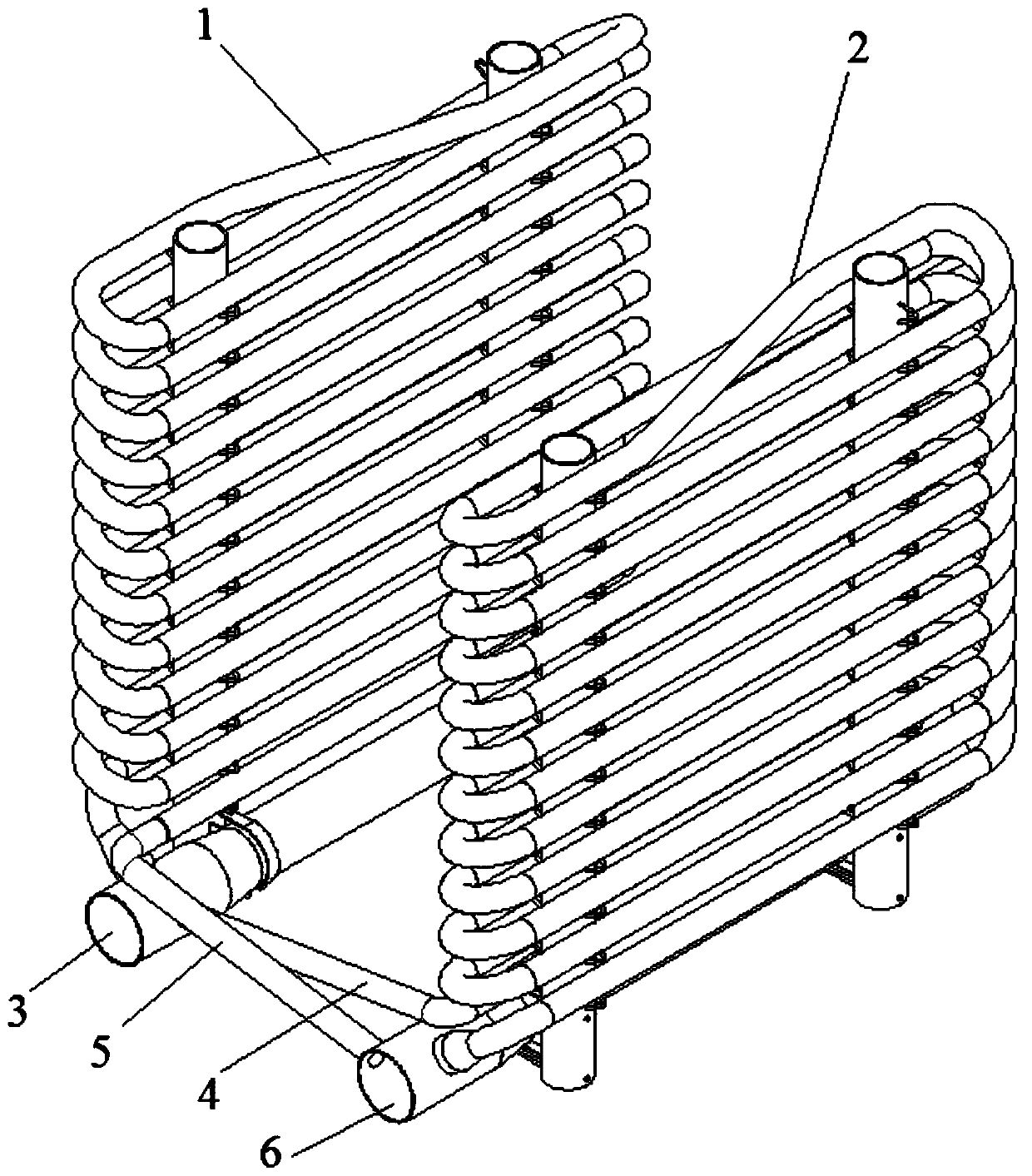

[0014] The first embodiment of the present invention provides a heat exchanger with uniform furnace temperature, which includes a plurality of horizontally parallel or series tube panels. Preferably, the number of the tube screen is two, such as figure 1 As shown, the heat exchanger with uniform furnace temperature includes two tube panels 1~2 combined in parallel. Preferably, each screen tube is supported and fixed by a support rod.

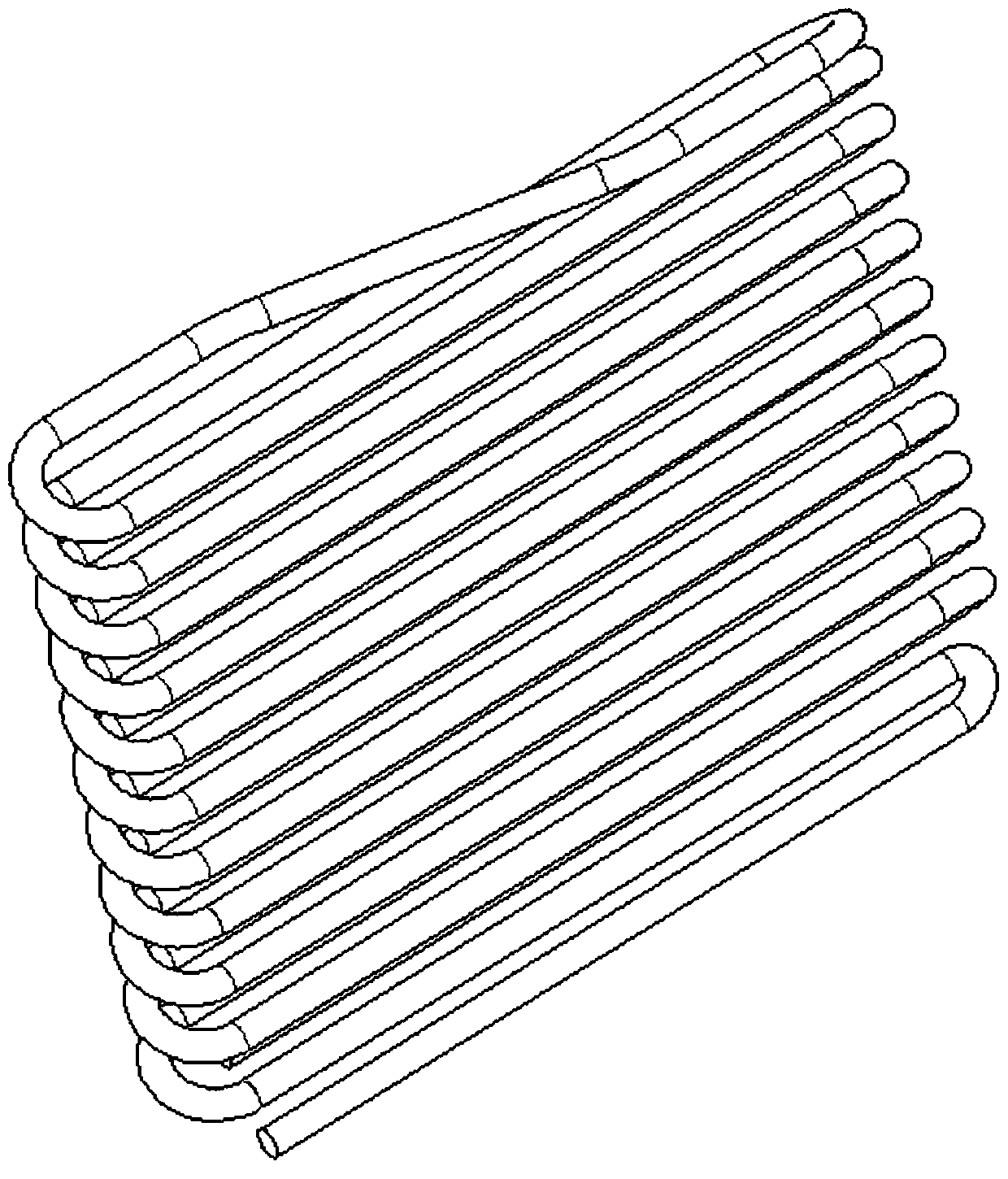

[0015] Please refer to figure 2 , Is a structural diagram of one of the tube panels. The tube panel is formed by spirally rising heat exchange tubes and then spirally descending them, wherein the heat exchange tubes that are set up are wound at intervals from the heat exchange tubes that are set down. Please keep reading figure 1 , Where the inlet 3 is the total inlet of the two tube panels, the outlet 6 is the total outlet of the two tube panels, the inlet shunt pipe 4; the outlet manifold pipe 5.

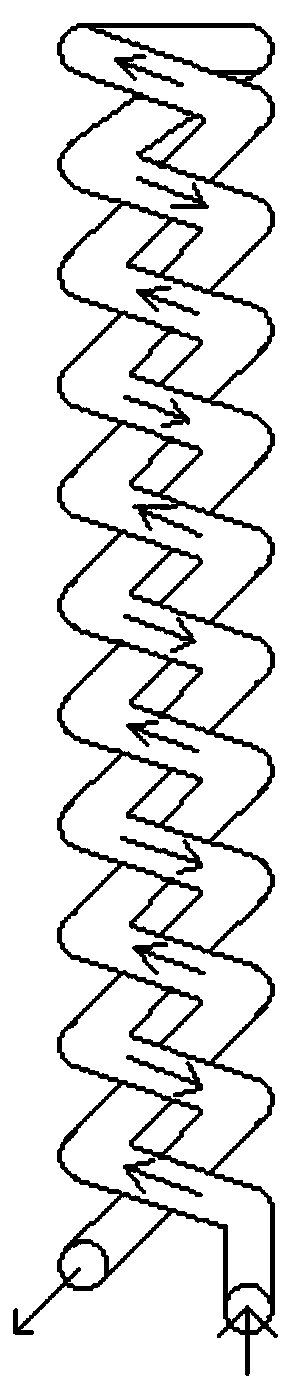

[0016] See image 3 , To indicate the flow dire...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap