A high-efficiency phase-change plate evaporator

A plate evaporator and phase change technology, applied in evaporator accessories, evaporation, chemical instruments and methods, etc., can solve the problem of low heat exchange efficiency, and achieve compact structure, high-efficiency vapor-liquid separation, and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following is a further description of the present invention, rather than a limitation of the present invention.

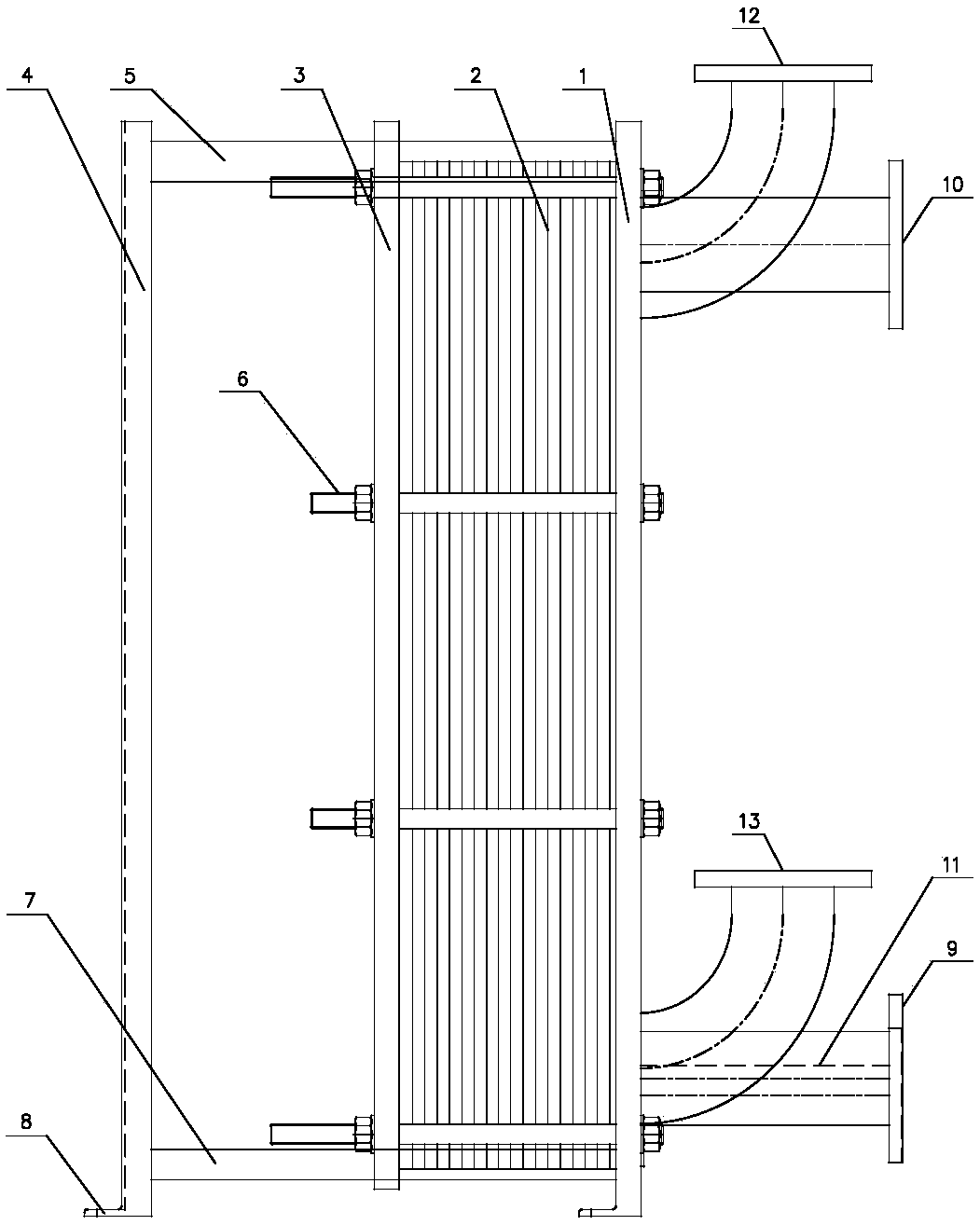

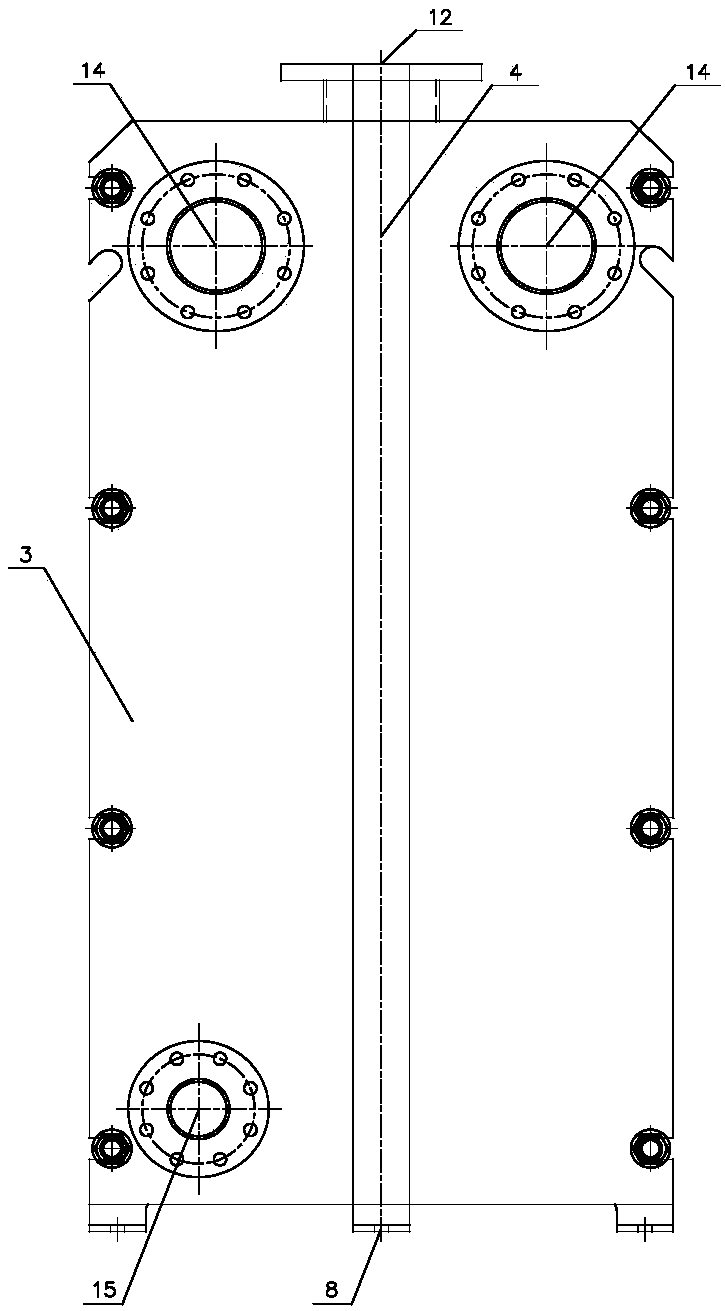

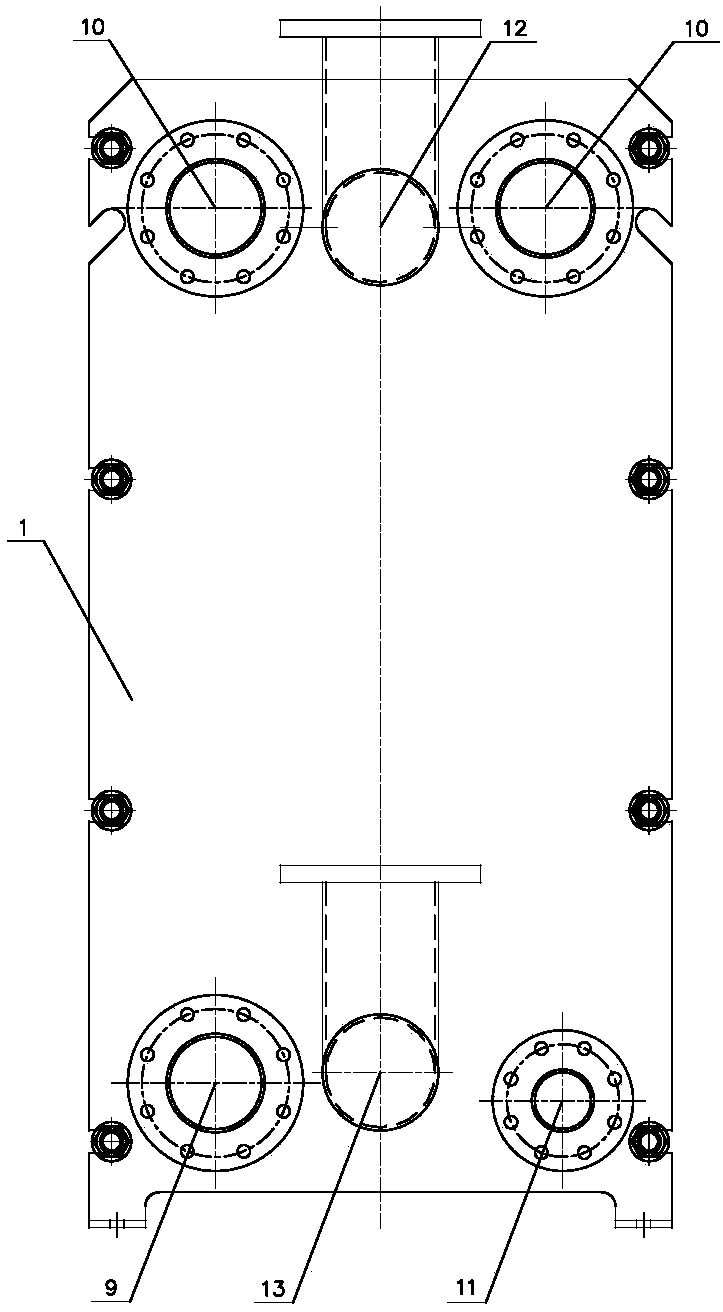

[0017] Such as Figure 1-Figure 4 The shown high-efficiency phase change plate evaporator includes a plurality of evaporative heat exchange plates 2, and the evaporative heat exchange plates 2 are arranged between the front end plate 1 and the rear end plate 3, and the front end plate 1 and the rear end plate The end plate 3 is connected by a tie rod 6, the top center of the evaporation heat exchange plate 2 is provided with a suspension hole 20, and the center of the bottom end is provided with a positioning hole 21, and the evaporation heat exchange plate 2 is fixedly connected to the upper end of the pillar 4 through the suspension hole 20 The upper guide rail 5 is suspended and connected, and is connected to the lower guide rail 7 fixedly connected to the lower end of the pillar 4 through the positioning hole 21; the pillar 4 is fixedly connected to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap