Printed board group

A technology of printed boards and elastic contacts, which is applied in the direction of contact parts, electrical components, coupling devices, etc., can solve the problems of high connection cost and poor flow capacity of printed boards, and achieve low cost, few components and easy installation. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

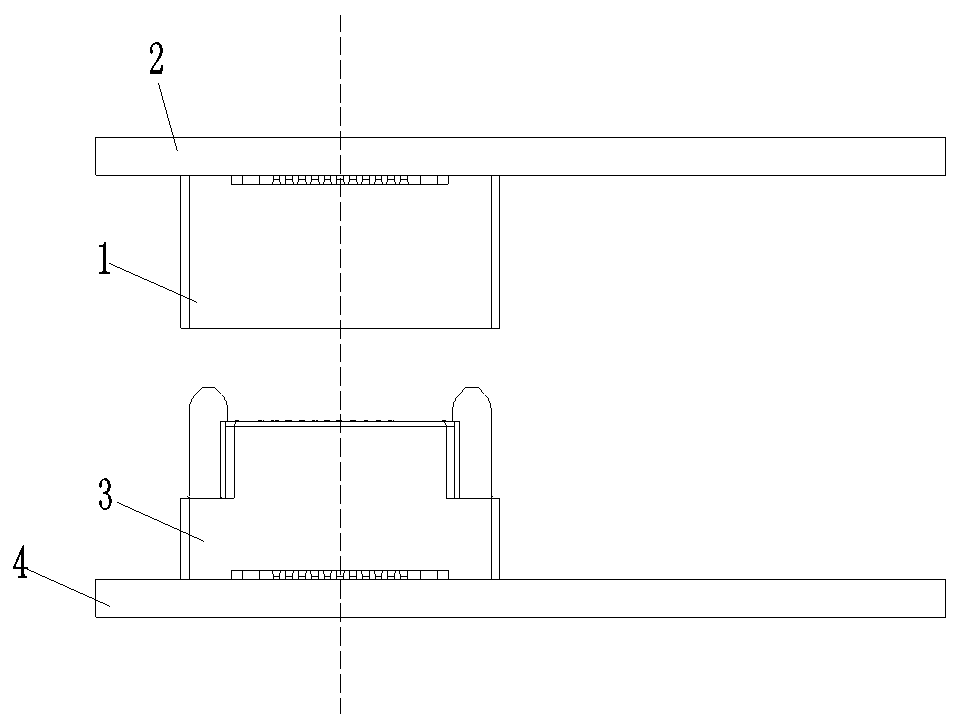

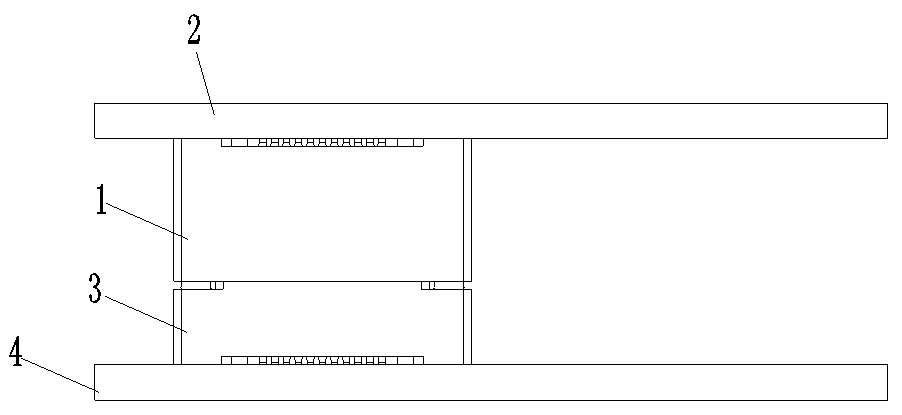

[0020] Example 1 of the printed board set, as Figure 3-4 As shown, in this embodiment, the printed board group has two printed boards, the two printed boards are parallel to each other and relatively fixed, the specific fixing method can be fixed by fasteners such as screws, or can be fixed by using The way of being stuck in the same housing is fixed, only need to realize the relative fixing of the two, and it is not necessary to list them one by one here. For ease of distinction, here image 3 The upper printed board is called the first board 101 , and the other printed board is called the second board 102 .

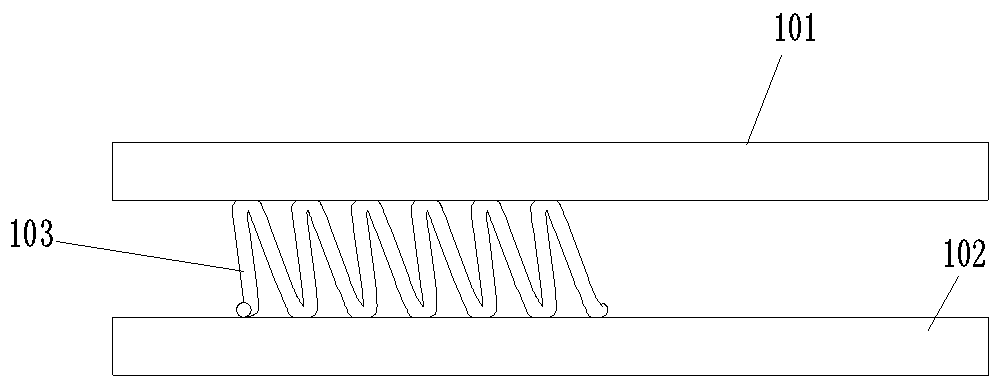

[0021] The first plate 101 and the second plate 102 are electrically connected through the elastic contact piece 103. The elastic contact piece 103 adopts a coil spring, and two conductive contact parts 21 are arranged on the outer peripheral s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com