Ecological colored spun yarn production device and method

A production device and color spinning technology, which is applied in the field of ecological color spinning production devices and can solve problems such as pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

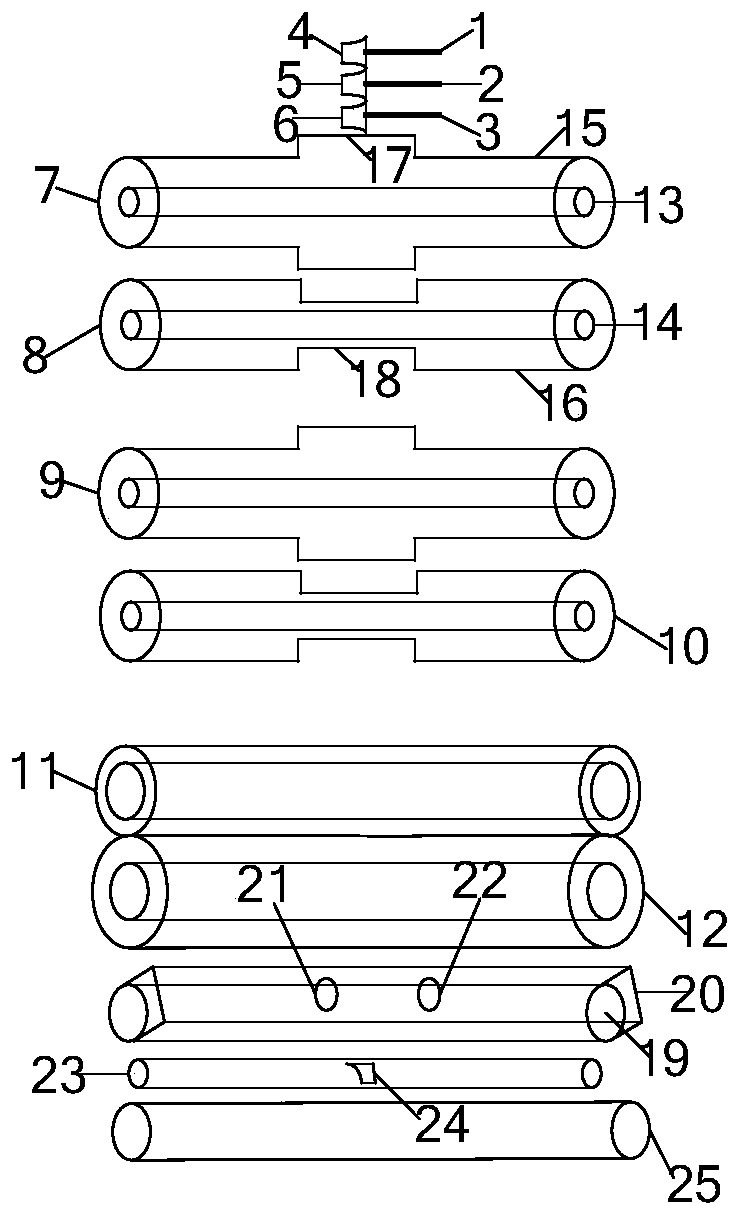

[0010] Depend on figure 1As shown, an ecological color spinning production device is spun by a ring spinning frame. The ring spinning frame is composed of 420 spindle positions or 516 spindle positions with the same structure, and each spindle position includes a drafting system. The drafting system includes the rear roller drafting pair consisting of the rear bottom roller 8 and the rear top rubber roller 7, the middle roller drafting pair consisting of the middle bottom roller 10 and the middle top rubber roller 9, the front bottom roller 12 and the front top roller. The front roller drafting pair composed of rubber rollers 11 is provided with a roving feeding bell mouth at the rear of the rear roller drafting pair. The roving feeding bell mouth includes an upper bell mouth 4, a middle bell mouth 5, a lower bell mouth 6, an upper bell mouth The structure of the bell mouth, the middle bell mouth and the lower bell mouth are exactly the same. The upper bell mouth, the middle b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com