Oral implant positioning drill bit

A drill bit and oral cavity technology, which is applied in the field of oral implant positioning drill bits, can solve problems such as unfavorable practical operation, easy drilling too deep, and inconvenient adjustment of the drill bit position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

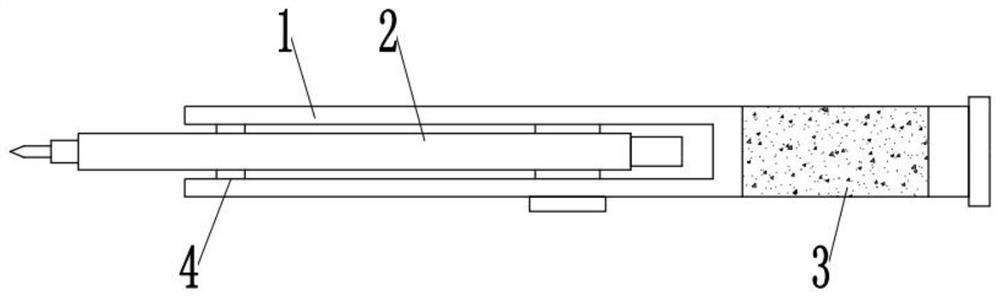

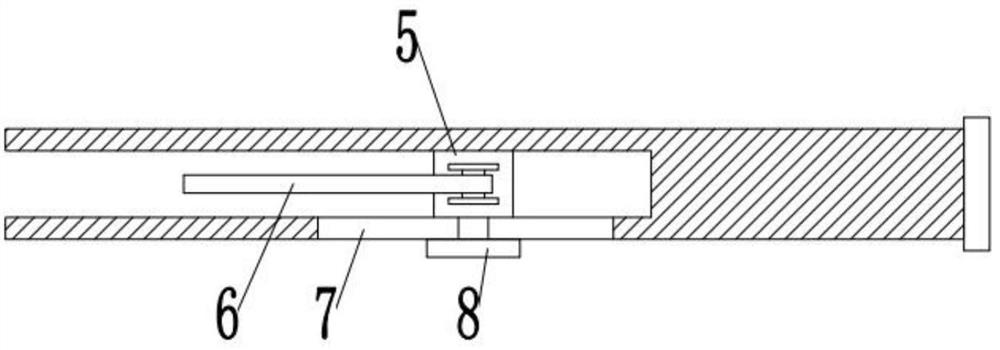

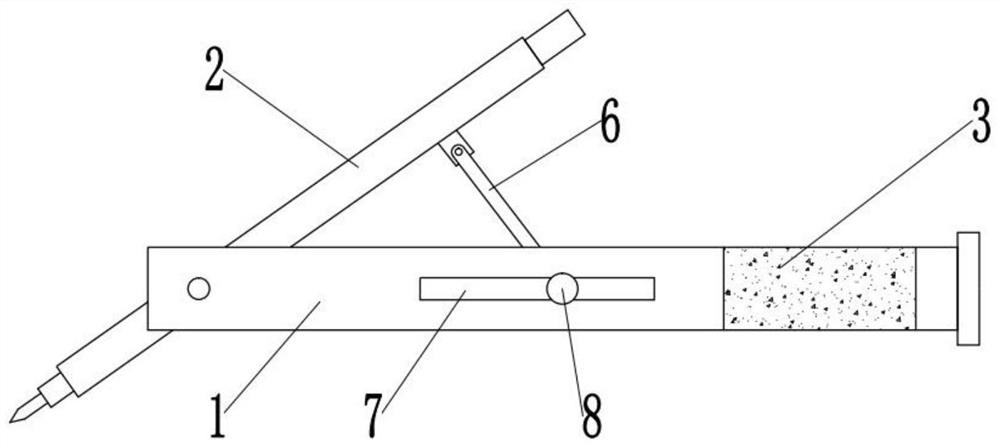

[0030] see Figures 1 to 4 , In the embodiment of the present invention, an oral implant positioning drill includes a frame 1 and a drilling mechanism 2; the frame 1 is a U-shaped structure, and the rear end of the frame 1 is provided with a holding part, The open end is provided with the drilling mechanism 2, and the drilling mechanism 2 is rotated on the frame 1 through the rotating shaft 4; the interior of the frame 1 is slidably installed with a sliding block 5, and the sliding block 5 is rotatably installed at one end of the push-pull rod 6 , the bottom of the drilling mechanism 2 is fixedly installed with a hinged seat, and the other end of the push-pull rod 6 is hingedly installed on the hinged seat. During the sliding process of the slider 5 inside the frame 1, the drilling mechanism is driven by the push-pull rod 6 2. Rotate to adjust the position of the drilling mechanism 2, so that the drilling mechanism 2 is precisely aligned with the teeth to be drilled;

[0031]...

Embodiment 2

[0036] see Figures 1 to 4 , In the embodiment of the present invention, an oral implant positioning drill includes a frame 1 and a drilling mechanism 2; the frame 1 is a U-shaped structure, and the rear end of the frame 1 is provided with a holding part, The open end is provided with the drilling mechanism 2, and the drilling mechanism 2 is rotated on the frame 1 through the rotating shaft 4; the interior of the frame 1 is slidably installed with a sliding block 5, and the sliding block 5 is rotatably installed at one end of the push-pull rod 6 , the bottom of the drilling mechanism 2 is fixedly installed with a hinged seat, and the other end of the push-pull rod 6 is hingedly installed on the hinged seat. During the sliding process of the slider 5 inside the frame 1, the drilling mechanism is driven by the push-pull rod 6 2. Rotate to adjust the position of the drilling mechanism 2, so that the drilling mechanism 2 is precisely aligned with the teeth to be drilled;

[0037]...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap