Perforating device for wooden products

A drilling device and technology for wood products, applied in the direction of fixed drilling machines, etc., can solve problems such as hole deviation, drilling, and inflexibility, and achieve the effects of increasing friction, convenient disassembly and assembly, and easy support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

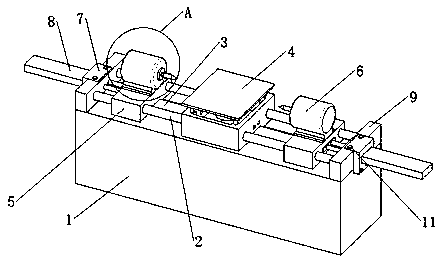

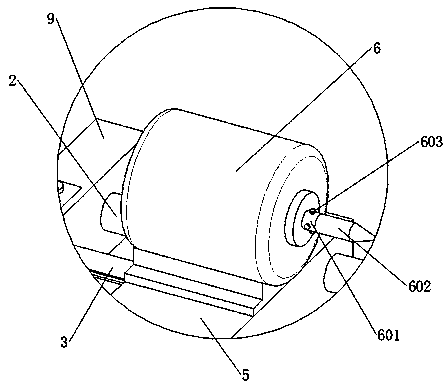

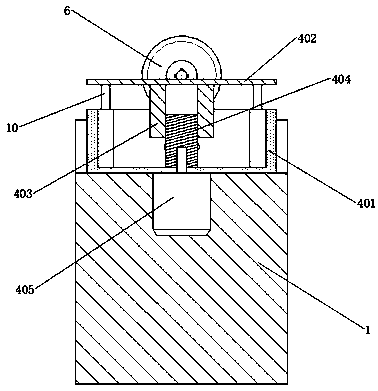

[0025] see figure 1 and Figure 4 , figure 1 It is a perspective view and a top view of the punching device of the present invention. A wood product punching device, comprising a workbench 1, the upper end of the workbench 1 is fixedly connected with a placing platform 4 and a pair of limiting plates 9, and an orientation shaft is fixedly connected between the limiting plate 9 and the side wall of the placing platform 4 2 and a pair of guide rails 3, the orientation shaft 2 is slidably connected with a movable seat 5 that matches the guide rail 3, and a damping layer is laid on the orientation shaft 2 to increase the friction between the orientation shaft 2 and the movable seat 5, so that the movable seat 5 It is not easy to be displaced due to the vibration generated when the punching device 6 is working. The upper end of the limiting plate 9 is fixedly connected with a mounting plate 7, and the mounting plate 7 is fixedly connected with an electric cylinder 8. The telescop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com