A punching die for leather production

A mold and punching technology, which is applied in the field of punching molds for leather production, can solve the problems of poor stability, increase or decrease the number of punching holes, and inaccurate punching positions, so as to achieve good stability and avoid poor positional stability. poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

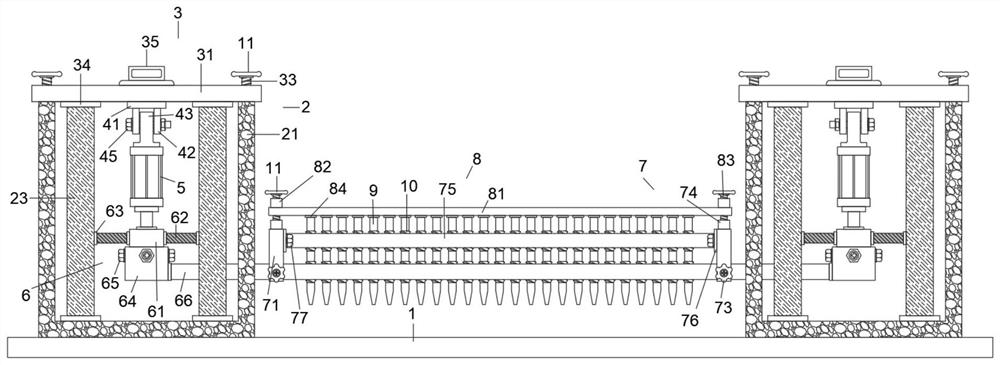

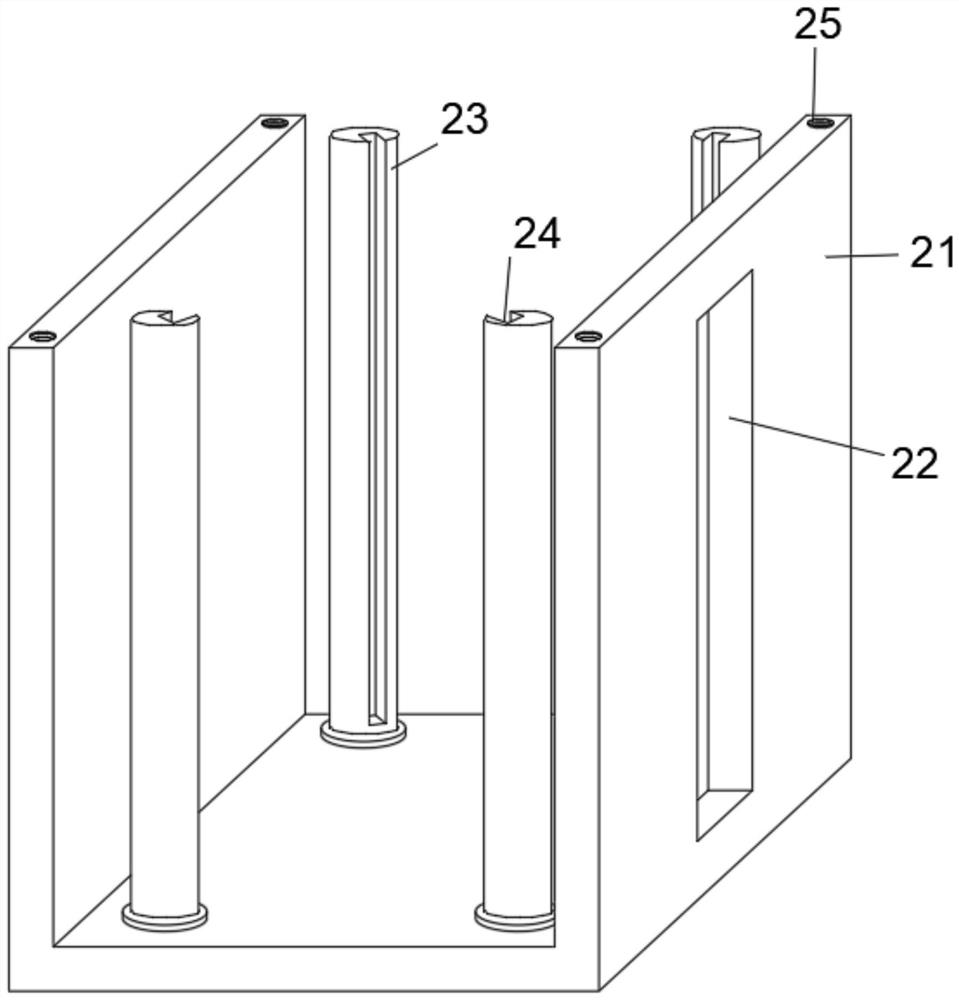

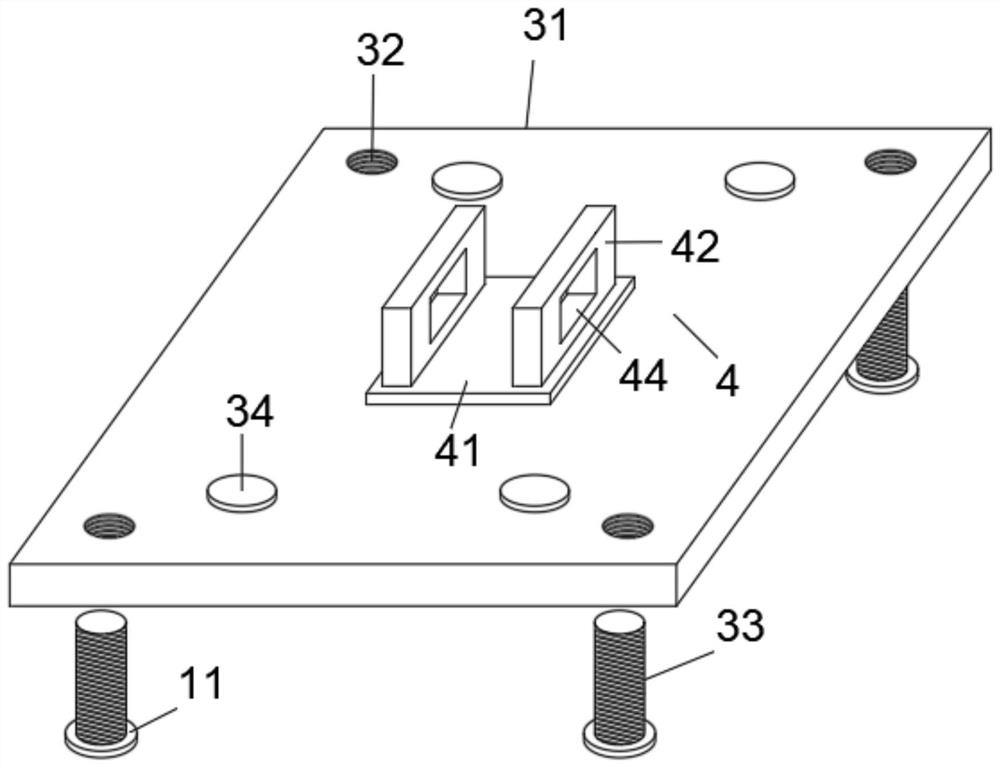

[0034] like Figure 1-9 As shown, this specific embodiment adopts the following technical solutions: a punching die for leather production, comprising a workbench 1 and a number of die bars 9, the top ends of the workbench 1 are provided with limiting mechanisms 2, and the two said The top of the limit mechanism 2 is connected with a cover plate mechanism 3 , two ends of the cover plate mechanisms 3 close to the limit mechanism 2 are connected with an installation mechanism 4 , and one end of the two installation mechanisms 4 away from the cover plate mechanism 3 and A hydraulic rod 5 is connected to the interior of the limiting mechanism 2, the output ends of the two hydraulic rods 5 are fixed with a connecting mechanism 6, and a reinforcing mechanism 7 is arranged between the two connecting mechanisms 6, and the reinforcing mechanism 7 A baffle mechanism 8 is arranged between the two limiting mechanisms 2;

[0035] The two limiting mechanisms 2 both include a U-shaped frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com